Method for mass production of water-soluble fluorescent carbon nanoparticles

A carbon nanoparticle, water-soluble technology, applied in the field of carbon nanoparticle preparation, to achieve the effect of excellent fluorescence properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

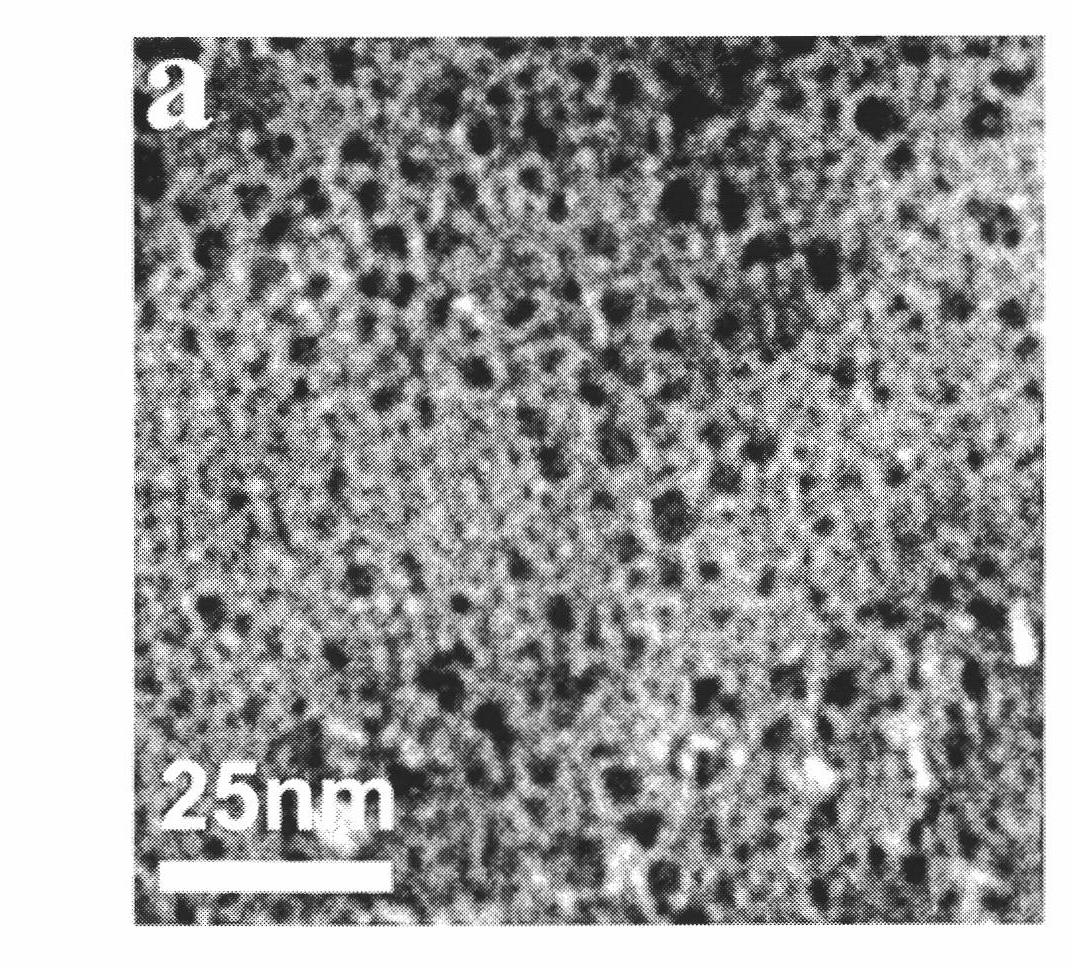

[0037] Take activated carbon as the carbon source for preparing carbon nanoparticles, take 2-4g of activated carbon and add 70-200ml of hydrogen peroxide to 30% hydrogen peroxide solution by mass percentage (or volume percentage), and put the mixture containing the two Put the glass reaction vessel (or other materials such as Teflon) on a magnetic stirrer and stir for 10 minutes, and make a black suspension after stirring evenly, then put the reaction vessel into a 300W power ultrasonic cleaner, and ultrasonically After 2 to 4 hours, after the reaction, vacuum filter the suspension (the filter paper used for suction filtration is 300 mesh medium-speed filter paper) to obtain a brown-black filtrate. Finally, the filtrate is slowly evaporated to dryness at 60°C to remove unreacted hydrogen peroxide. The obtained black solid was dissolved in deionized water at room temperature to obtain purified water-soluble carbon nanoparticles. The purity of the activated carbon and hydrogen p...

Embodiment 2

[0043] Take activated carbon as the carbon source for preparing carbon nanoparticles, get 3g activated carbon and join 100ml hydrogen peroxide mass percentage (or volume percentage) in the hydrogen peroxide solution of 40%, the glass reaction vessel ( or other material reaction vessels, such as Teflon) were placed on a magnetic stirrer and stirred for 15 minutes, and a black suspension was formed after stirring evenly, and then the reaction vessel was placed in a 300W power ultrasonic cleaner, and ultrasonic 3.5 at a frequency of 40KHz After the reaction, the suspension was vacuum-filtered (300 mesh medium-speed filter paper for suction filtration) to obtain a brown-black filtrate, and finally the filtrate was slowly evaporated to dryness at 70°C to remove unreacted hydrogen peroxide, and the obtained The black solid was dissolved in deionized water at room temperature to obtain purified water-soluble carbon nanoparticles. The purity of the activated carbon and hydrogen peroxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com