Automatic liquid-replenishing device for diffusion furnace in solar battery production

An automatic liquid replenishing device and solar cell technology, applied in the direction of diffusion/doping, circuit, crystal growth, etc., can solve the problems of affecting the ambient temperature and production efficiency of the source bottle, affecting the accuracy of the liquid level, and increasing the investment cost. Achieve the effects of improving product quality and process stability, high liquid level control accuracy, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

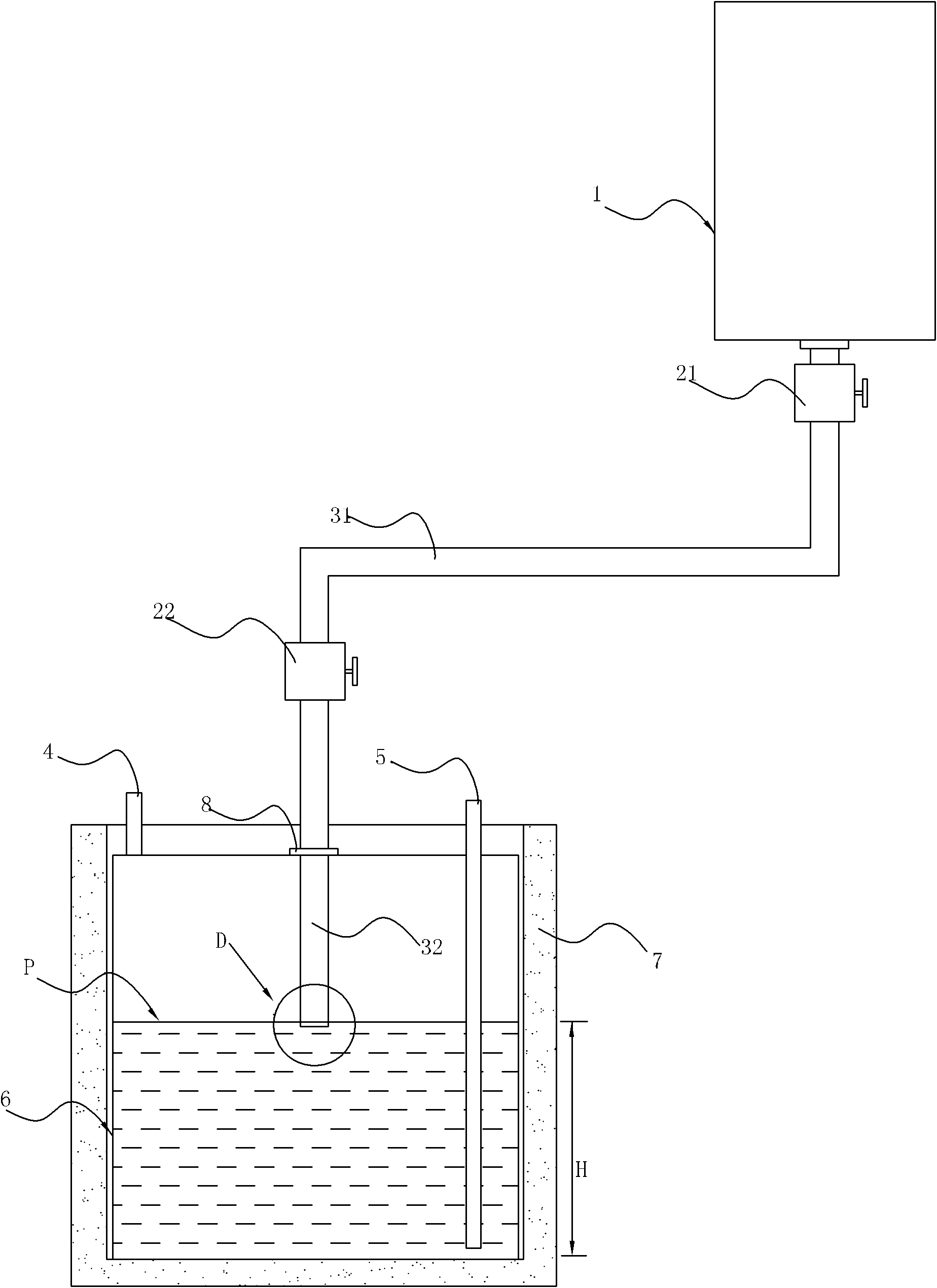

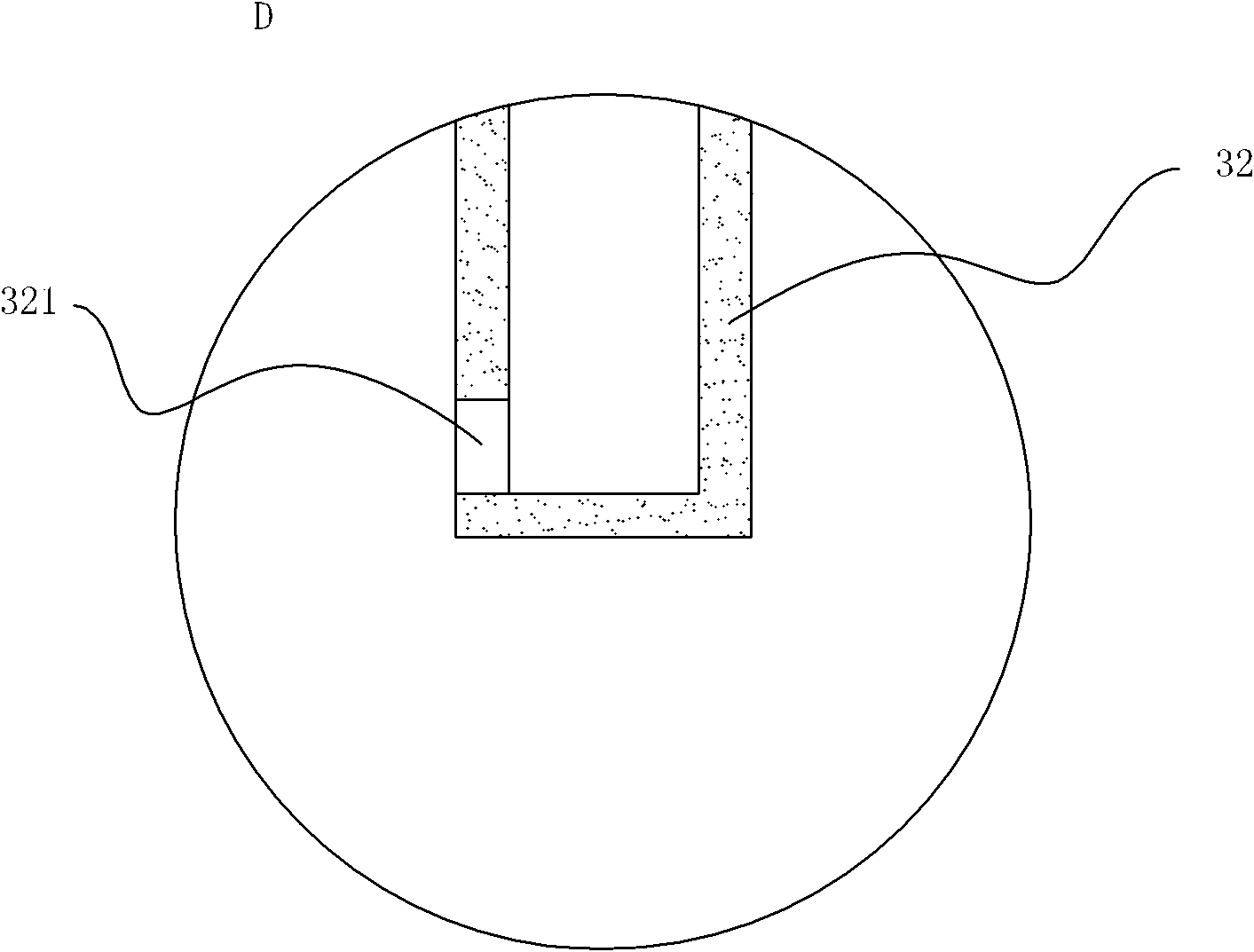

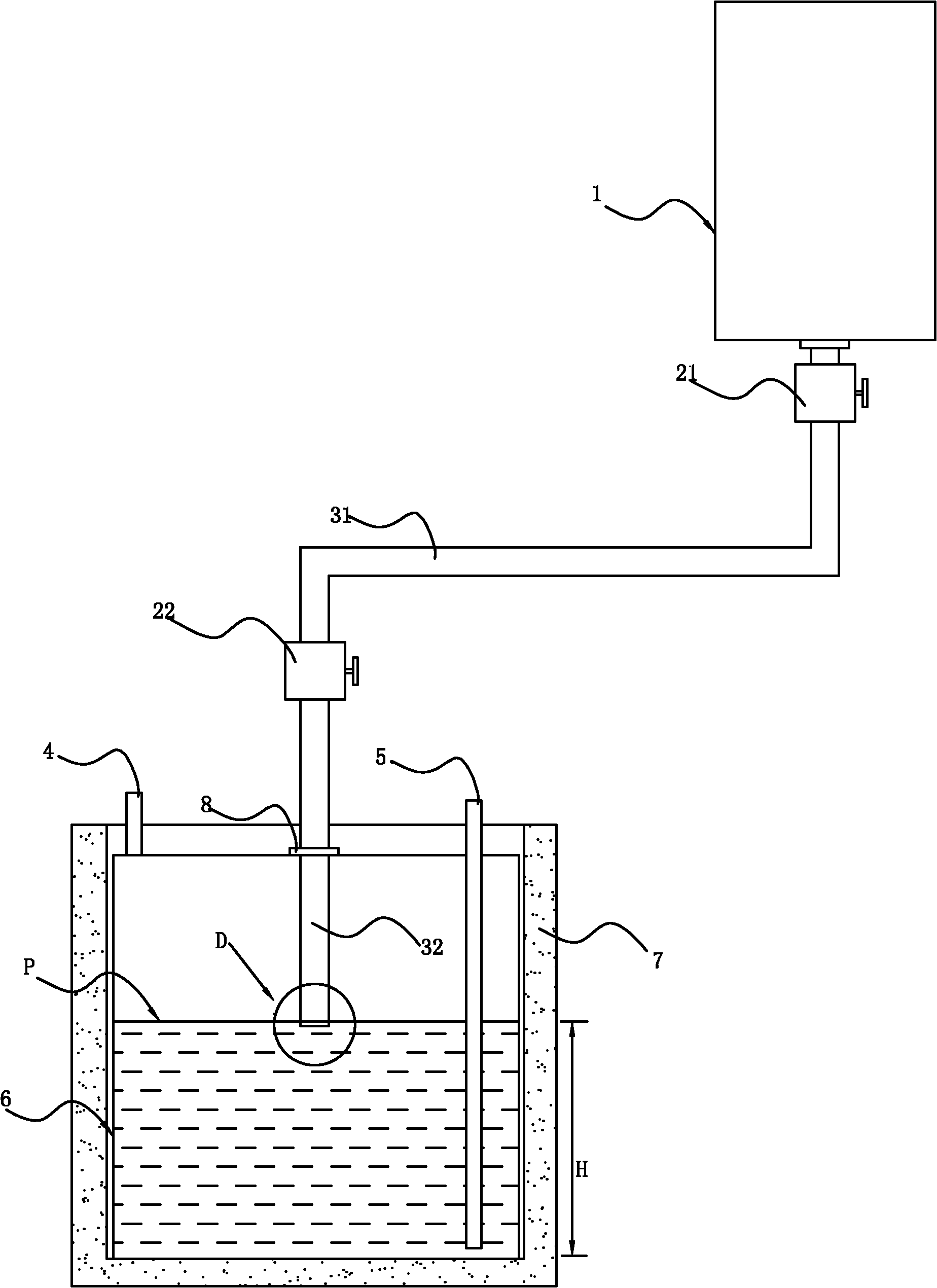

[0020] Such as figure 1 Shown is an embodiment of an automatic replenishment device for a diffusion furnace in solar cell production, including a phosphorus oxychloride liquid storage tank 1 and a source bottle 6 installed in a constant temperature tank 7, and 1 phosphorus oxychloride liquid storage tank The mouth is downwardly arranged at a height above the source bottle 6 to form potential energy; the phosphorus oxychloride liquid storage tank 1 is connected with the source bottle 6 by a pipeline, and its connection structure is: the mouth of the phosphorus oxychloride liquid storage tank 1 and the The inlet of the shut-off valve 21 is connected, the outlet of the shut-off valve 21 is connected with the upper end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com