Pure natural aromatic mothproof solid wood composite floor

A solid wood composite flooring, pure natural technology, applied in the field of pure natural aromatic mothproof solid wood composite flooring, can solve the problems of not being able to prevent insects, termites, cockroaches, etc., and achieve the effect of eliminating peculiar smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

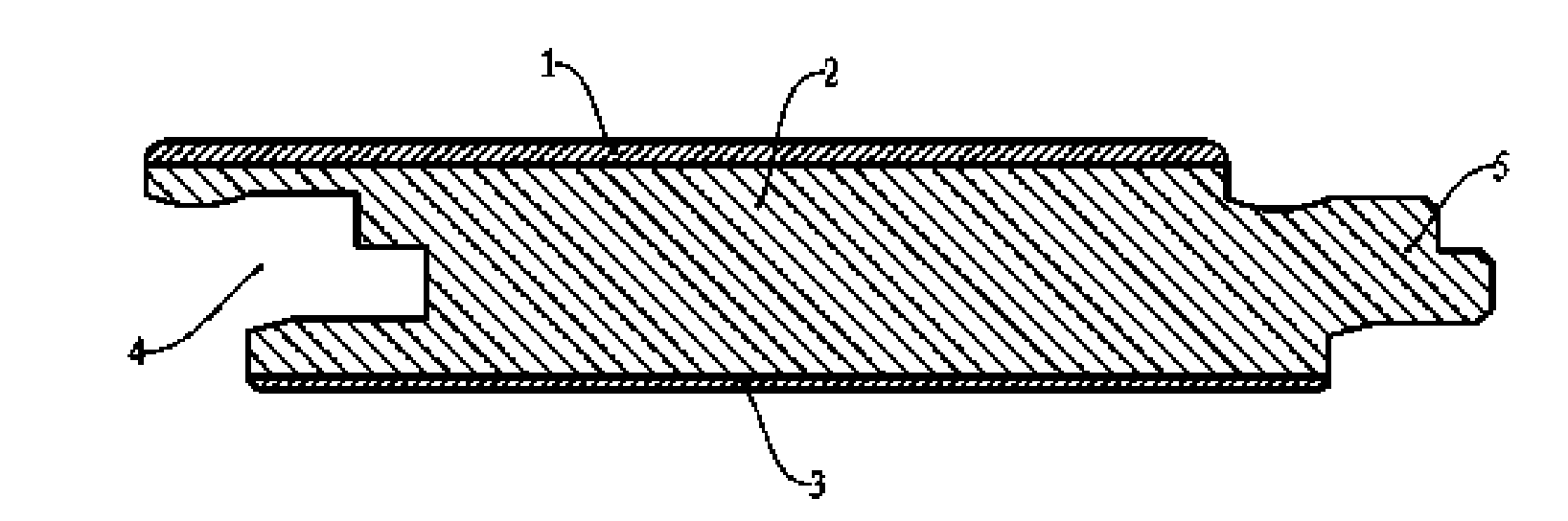

[0020] see figure 1 , figure 1 It is a cross-sectional view of the floor of the first embodiment. From top to bottom, it is the upper surface layer 1, the middle layer 2 and the bottom layer 3. In this figure, it can be seen that the two sides of the lath-shaped main body are provided with grooves, and the grooves can have A variety of structural forms, the left side in this example is a groove 4, the right side is a tenon 5, and the other two sides that are not visible in this figure are similar to these two sides and also have grooves or tenons.

[0021] The upper surface layer 1 adopts thin veneer of precious tree species with a thickness of 0.6-3mm, the bottom layer 3 adopts thin veneer of poplar or other fast-growing forests, and the middle layer 2 adopts a layer of camphor wood. If the width of the slats is large, this layer of incense The middle layer 2 that camphor wood constitutes can be splicing structure, that is, middle layer 2 can be the single layer that two pie...

no. 2 example

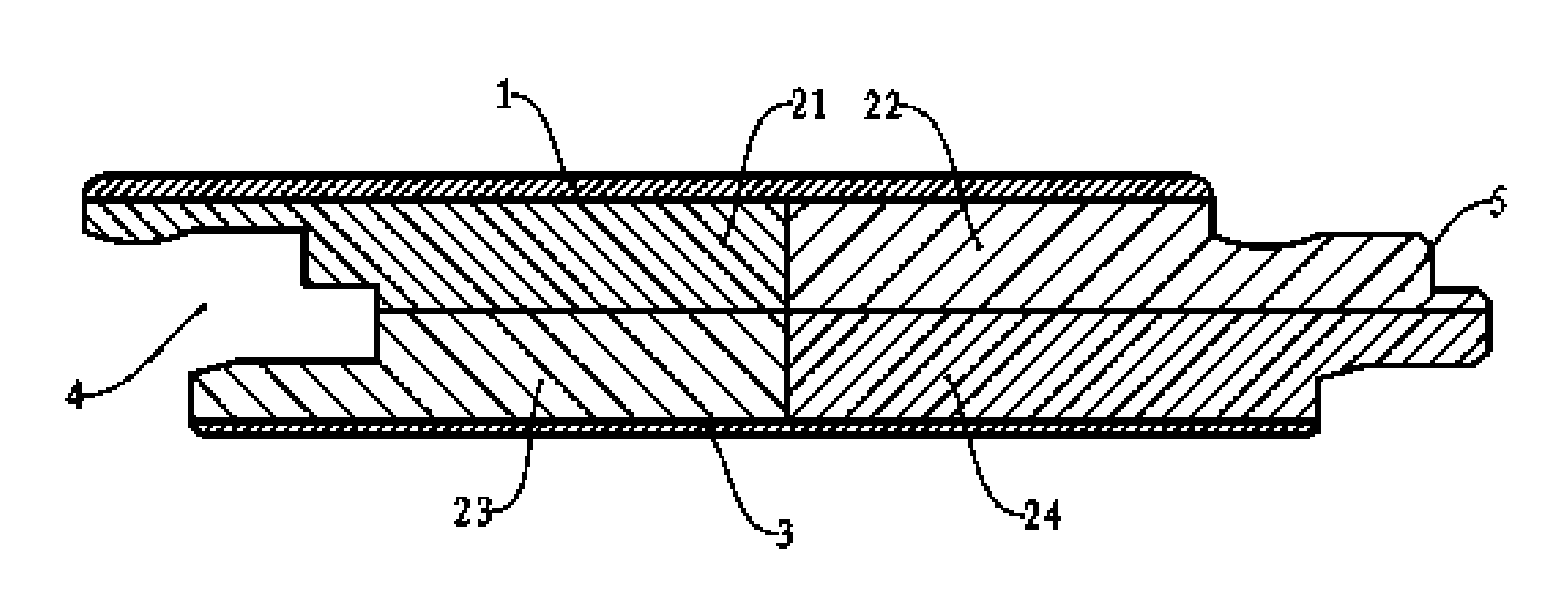

[0023] see figure 2 , this example is basically the same as the first embodiment, the difference is the structure of the middle layer, the middle layer is made of two layers, the first layer is made of camphor wood board 21 and camphor wood board 22, and the second layer is made of camphor wood board 22. Two pieces of plank 23 and camphor plank 24 are spliced together. That is to say, under the same situation as the thickness of the middle layer in the first embodiment (up and down directions in each drawing), this example can make the camphor wood board relatively thinner in thickness to be used, so as to save the camphor wood material.

no. 3 example

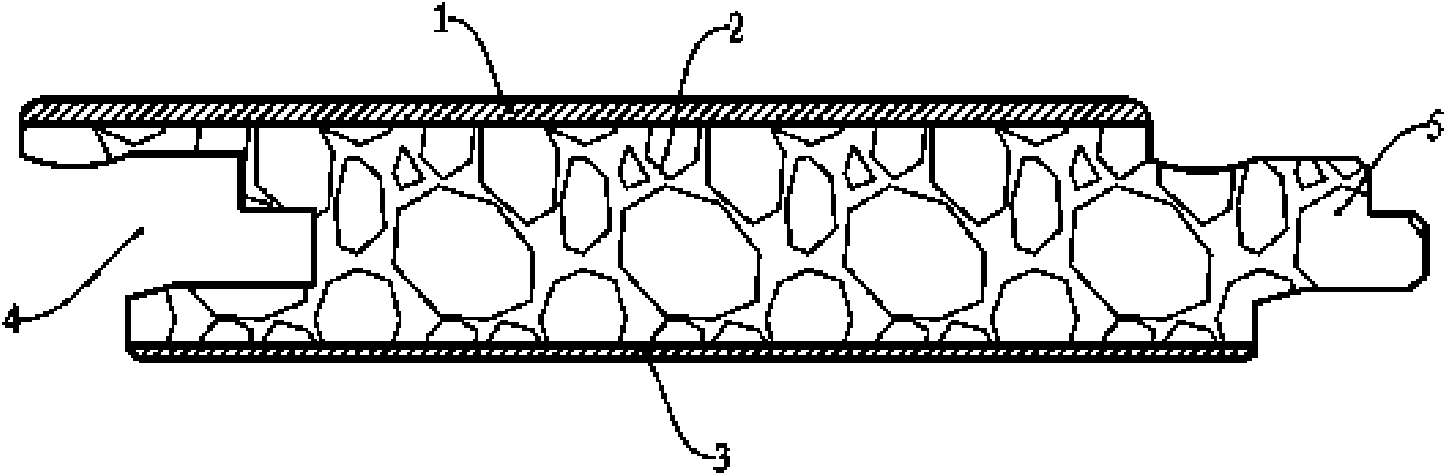

[0025] see image 3 , this example is basically the same as the first embodiment, and the difference is the structure of the middle layer 2, the middle layer 2 is made of an integrated board made of camphor wood small blocks, and the structure and manufacturing method of the integrated board are as follows: some short camphor wood The wood is manufactured into the required size and shape for bonding and gluing, and defects such as knots and decay should be removed as much as possible before gluing. When matching boards, the defective wood is scattered and arranged, arranged according to the strength of the laminates and fully dried to ensure that the moisture content of each part is consistent, and then machined to form large boards that meet the size requirements of solid wood composite flooring by hot pressing. That is to form a camphor wood integrated board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com