Method for manufacturing light-emitting diode lamp

A technology for light-emitting diodes and a manufacturing method, which is applied to semiconductor devices, light sources, point light sources, etc. of light-emitting elements, can solve the problems of occupying space, increasing costs, and consuming manpower, saving man-hours and costs, and reducing the space occupied. , the effect of increasing the heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

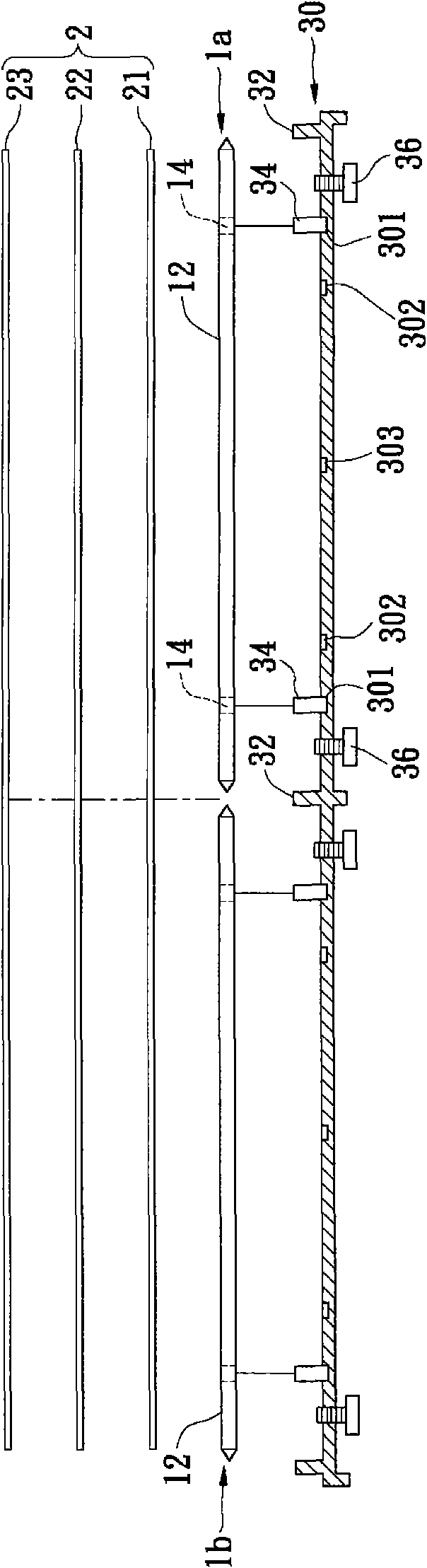

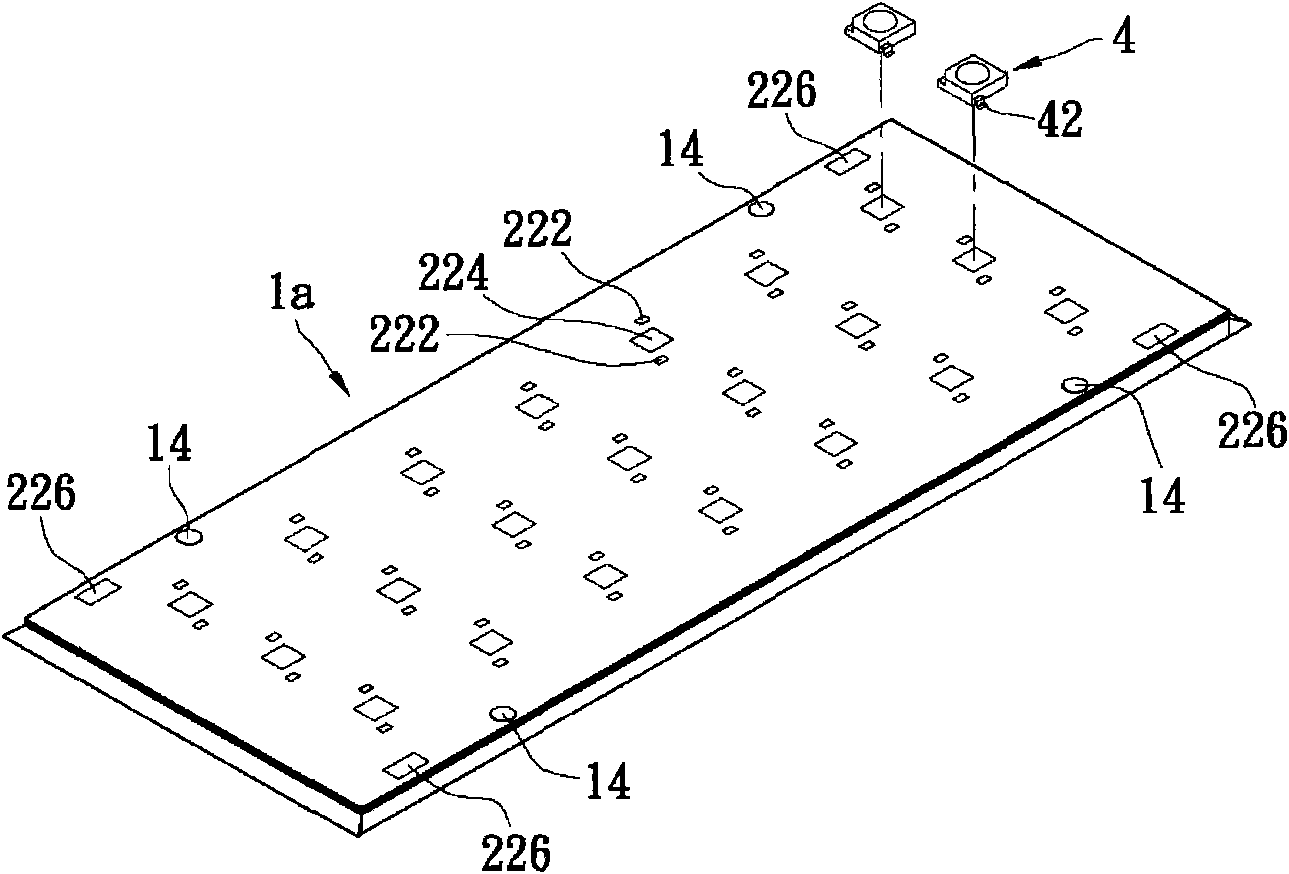

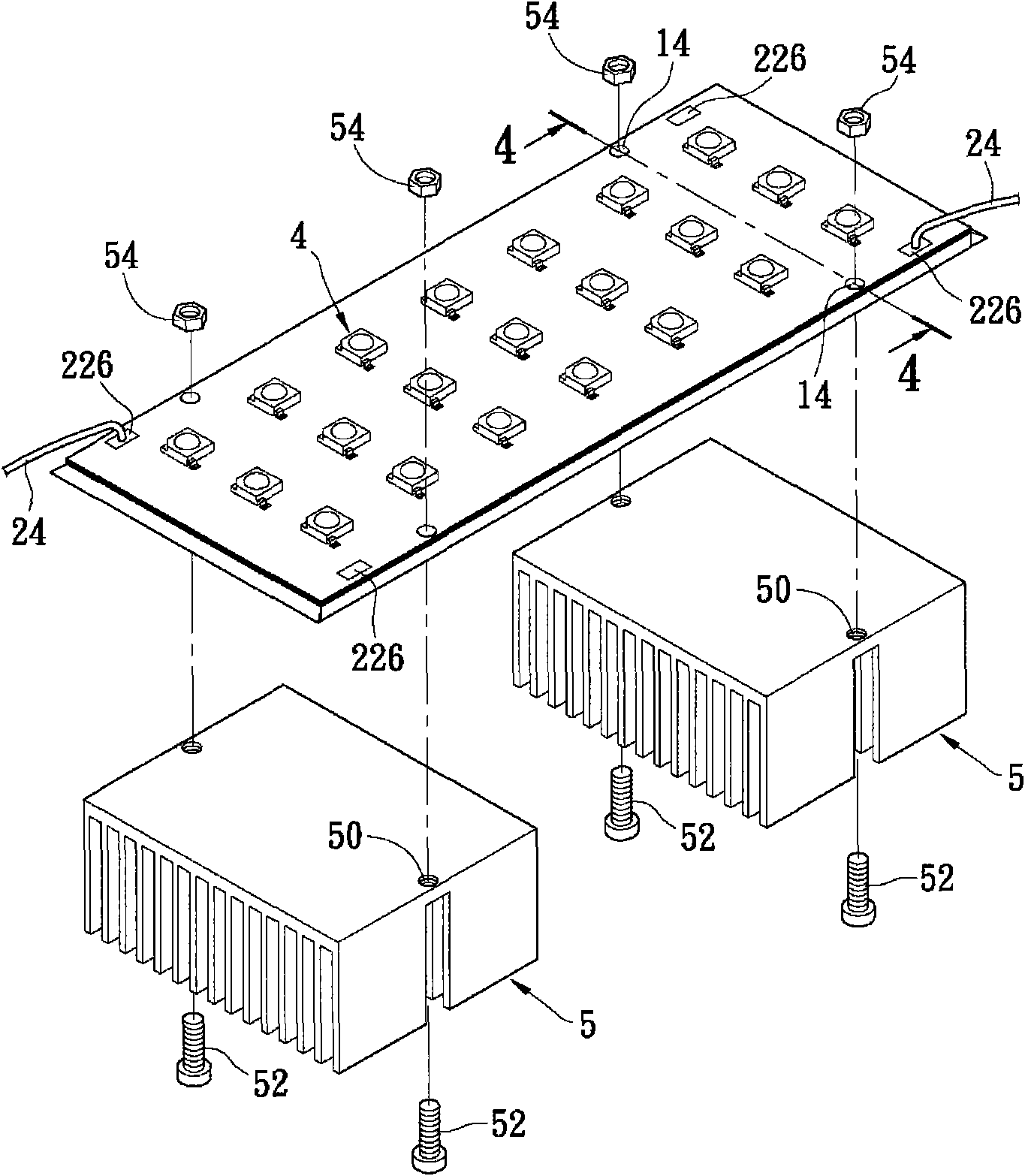

[0038] Please refer to figure 1 , is a schematic diagram of the manufacturing method of the light-emitting diode lamp of the present invention. The manufacturing method of the LED lamp of the present invention includes the following steps: firstly, at least one flat heat pipe 1a, 1b is provided, and a flat surface 12 is formed on each of them. The flat heat pipes 1a, 1b are preferably elongated plates. In this embodiment, since the flat heat pipe 1a and the flat heat pipe 1b are symmetrical, the following description will only take the flat heat pipe 1a as a representative.

[0039] The step of forming the flat surface 12 on the flat heat pipe 1a, 1b includes: firstly, polishing a plane of the flat heat pipe 1a, 1b; The flat surface 12 is for directly forming a printed circuit layer 2 on the flat heat pipes 1a, 1b.

[0040] Before forming the printed circuit layer 2, in order to fix the flat heat pipes 1a, 1b. The present invention provides a jig 30 on which the flat heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com