A high thermal conductivity aluminum-based copper clad laminate

An aluminum-based copper-clad laminate with high thermal conductivity technology, which is applied in lamination devices, lamination, and layered products, etc., can solve the problem of poor bonding performance between the thermally conductive adhesive layer and copper foil and aluminum plate, dip soldering resistance and voltage resistance. and other problems, to reduce the existence of defects, improve the resistance to dip soldering and voltage resistance, and shorten the heat conduction path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

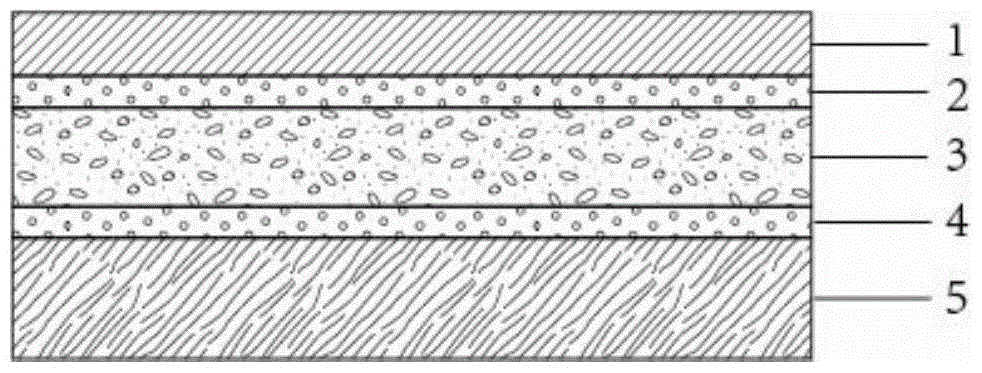

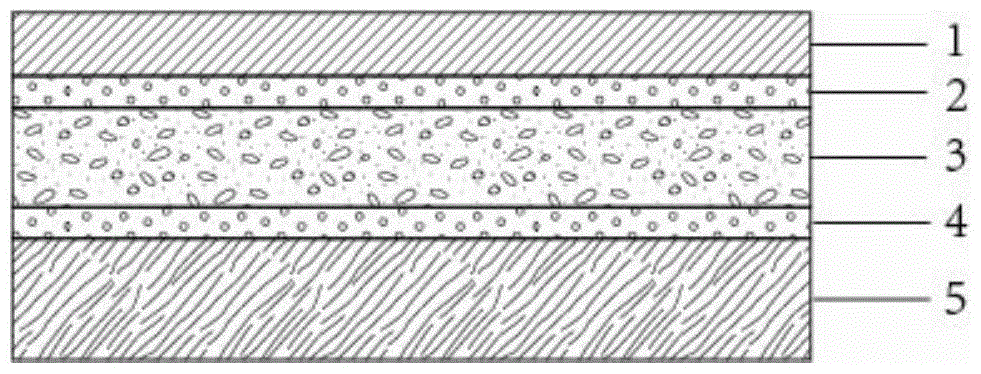

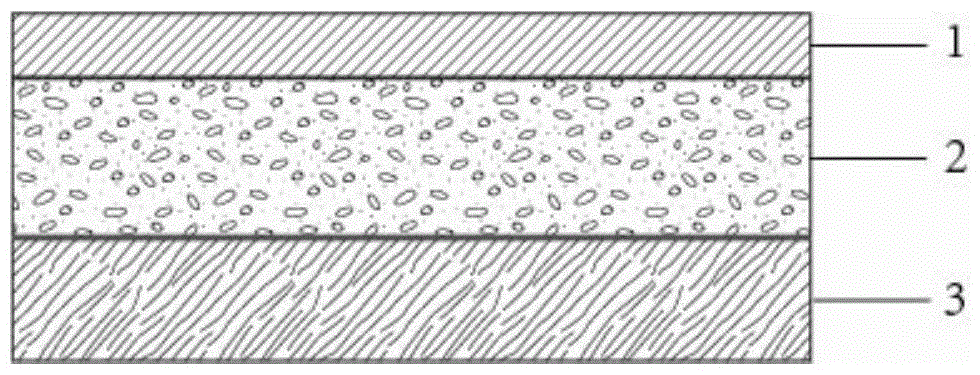

[0031] Coat the first layer of glue and the third layer of glue on the rough surface of the copper foil and the aluminum plate. The coating thickness of the first layer of glue and the third layer of glue are both 7 μm. Imide resin, no filler, the main components of the third layer of glue are polyimide resin and alumina filler, wherein the filler content is 20wt%, the particle size D50 is 1 μm, and D100 is 2 μm. The second layer of glue Coating on the rough surface of copper foil coated with the first layer of glue or aluminum plate coated with the third layer of glue, the thickness of the second layer of glue coating is 45μm, and the main component of the second layer of glue is polyimide Resin and alumina filler, the filler content is 70wt%, the particle size D50 is 5 μm, and the D100 is 10 μm. The solvent was evaporated at 170°C, according to figure 2 As shown, it is stacked and laminated at 350°C to obtain a high thermal conductivity aluminum-based copper clad laminate....

Embodiment 2

[0033]Coat the first layer of glue and the third layer of glue on the rough surface of the copper foil and the aluminum plate. Glue, the main components of the glue are bisphenol A epoxy resin, dicyandiamide and alumina filler, the filler content is 40wt%, the particle size D50 is 2μm, and the D100 is 6μm. The second layer of glue is coated on the The rough surface of the copper foil of the first layer of glue or the aluminum plate coated with the third layer of glue, the coating thickness of the second layer of glue is 90 μm, and the main components of the glue of the second layer of glue are biphenyl epoxy resin, rubber modified permanent epoxy resin, aromatic amine curing agent and spherical alumina filler, the filler content is 90wt%, the particle size D50 is 25 μm, and the D100 is 60 μm. The solvent was evaporated at 120°C, according to figure 2 As shown, it is stacked and laminated at 190°C to obtain a high thermal conductivity aluminum-based copper clad laminate.

Embodiment 3

[0035] Coat the first layer of glue and the third layer of glue on the rough surface of the copper foil and the aluminum plate. Glue, the main components of the glue are biphenyl epoxy resin, phenolic resin, aromatic amine curing agent and alumina filler, the filler content is 70wt%, the particle size D50 is 4μm, D100 is 10μm, the second One layer of glue is coated on the rough surface of copper foil coated with the first layer of glue or the aluminum plate coated with the third layer of glue. The thickness of the second layer of glue is 80 μm, and the main component of the second layer of glue is biphenyl Epoxy resin, bisphenol A benzoxazine resin, phenoxy resin, aromatic amine curing agent and alumina filler, the filler content is 90wt%, the particle size D50 is 10 μm, and the D100 is 35 μm. The solvent was evaporated at 150°C, according to figure 2 As shown, it is stacked and laminated at 230°C to obtain a high thermal conductivity aluminum-based copper clad laminate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com