Electrical removal device of liquid crystal panel substrate

A technology for liquid crystal panels and substrates, which can be used in static electricity, electrical components, optics, etc., and can solve problems such as slow removal of electricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Hereinafter, embodiments of the present invention will be described in detail based on the drawings.

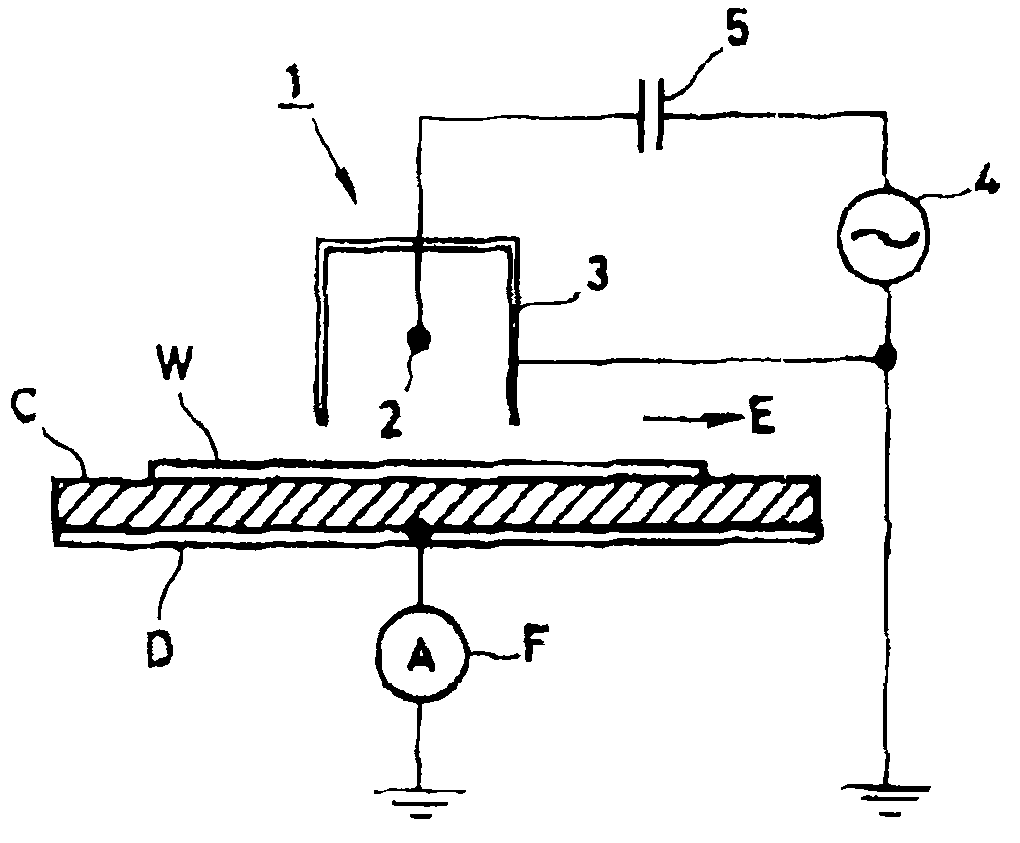

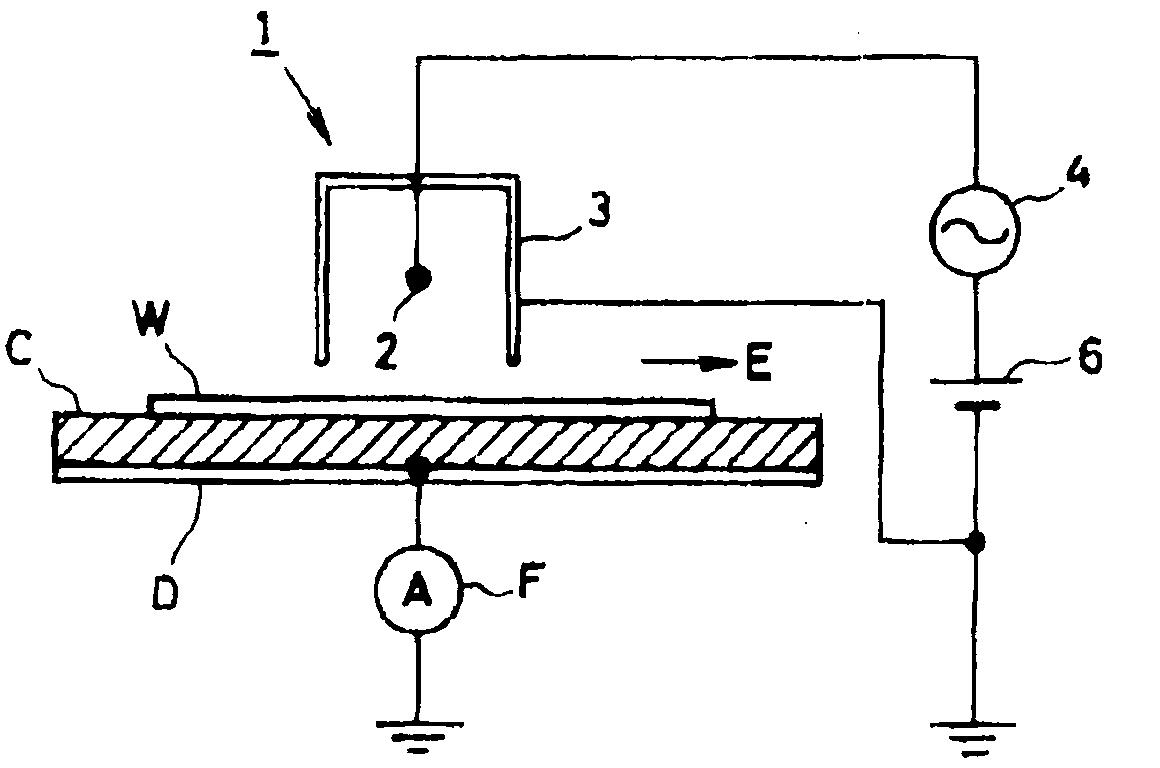

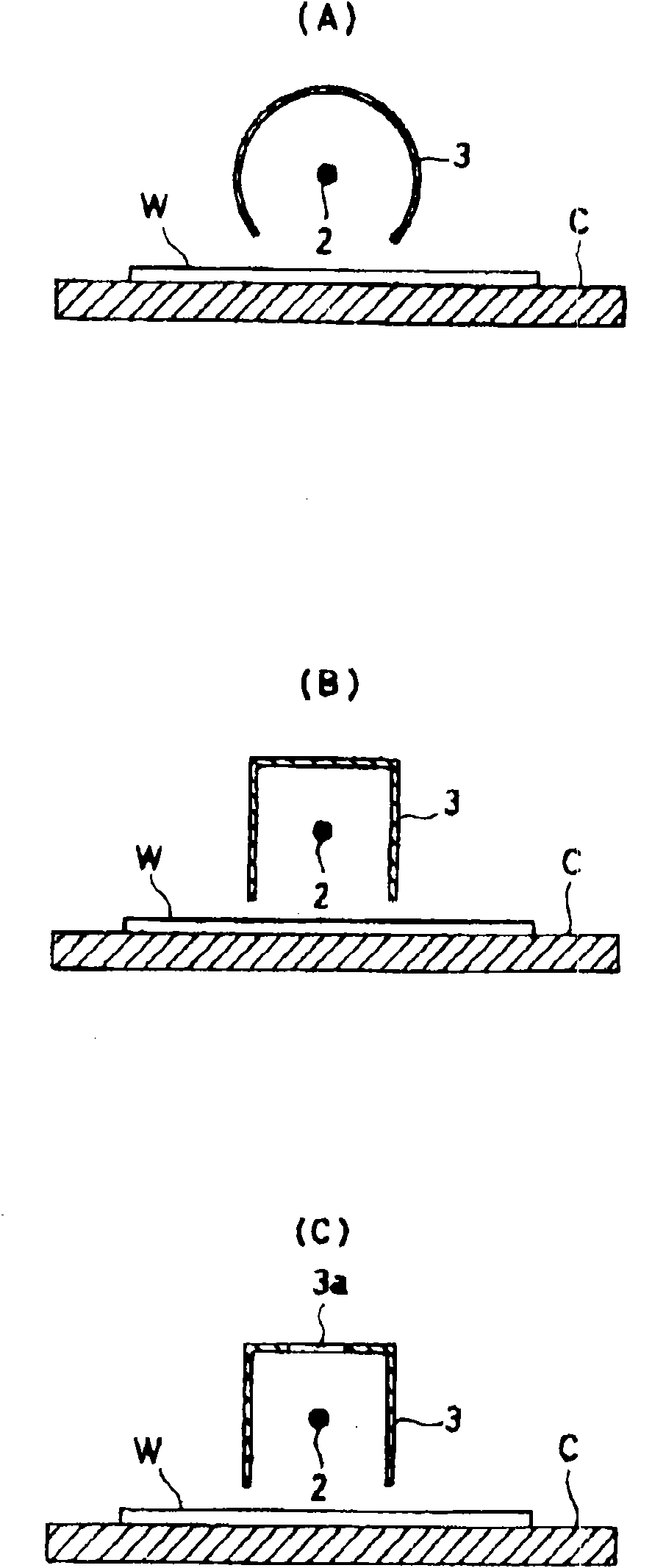

[0074] figure 1 It is a diagram showing an example of the basic structure of the present invention. In the same diagram, an ionizer 1 is composed of a discharge electrode 2 made of metal filaments and a grounded conductive case 3 covering the discharge electrode 2 . The transport carrier C or the conductive layer D is grounded, and a liquid crystal panel substrate W is placed on the transport carrier C, and an ionizer is placed above the liquid crystal panel substrate W in a manner perpendicular to the transport direction E of the liquid crystal panel substrate W or obliquely. Device 1.

[0075] The AC high voltage of the AC high voltage power supply 4 is applied to the discharge electrode 2 of the ionizer 1 via the capacitor element 5 , and a discharge current from which a DC current component has been removed is supplied through the capacitor element 5 . Then, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com