Static elimination processing method for wool knitted fabric

A wool knitted fabric, static electricity elimination technology, applied in knitting, weft knitting, fabric surface trimming, etc., can solve the problems of wool knitted fabrics that cannot meet the needs of static electricity, human blood pH rise, electrical component damage, etc., to improve antistatic Friction, long-lasting antistatic effect, anti-local accumulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A static elimination processing method for wool knitted fabrics, the method is as follows:

[0026] (1) Pretreatment: soak the wool yarn in an antistatic solution and then dry it for pretreatment;

[0027] The wool mass percentage content of the wool yarn is 40%, and the antistatic solution is composed of dihydrogenated tallow dimethyl ammonium chloride, isomeric tridecyl alcohol polyoxyethylene ether, fatty alcohol ether phosphate, phenol ether Phosphate ester and water are composed at a mass ratio of 4:3:5:1:120, the soaking time is 25 minutes, the soaking temperature is 45°C, the drying temperature is 110°C, and the drying time is 50 minutes.

[0028] (2) Yarn feeding: the wool yarn and conductive fiber are sent to the loop knitting area of the knitting machine;

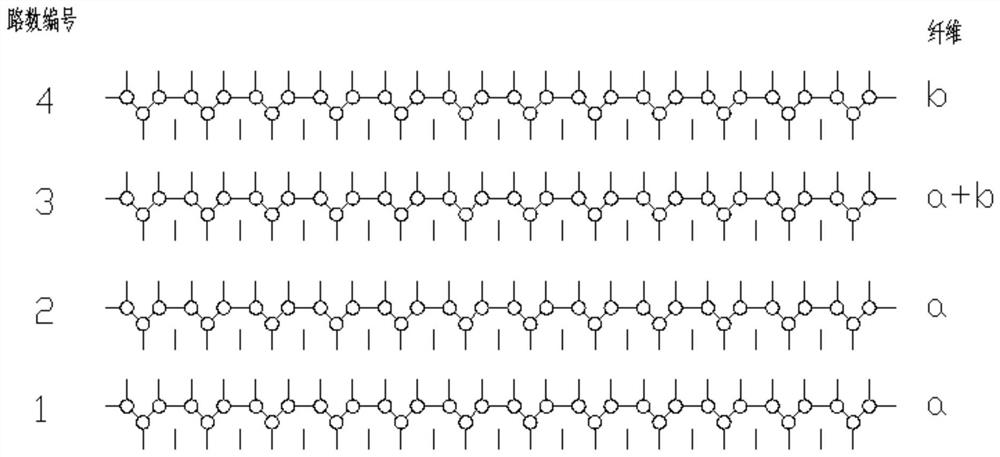

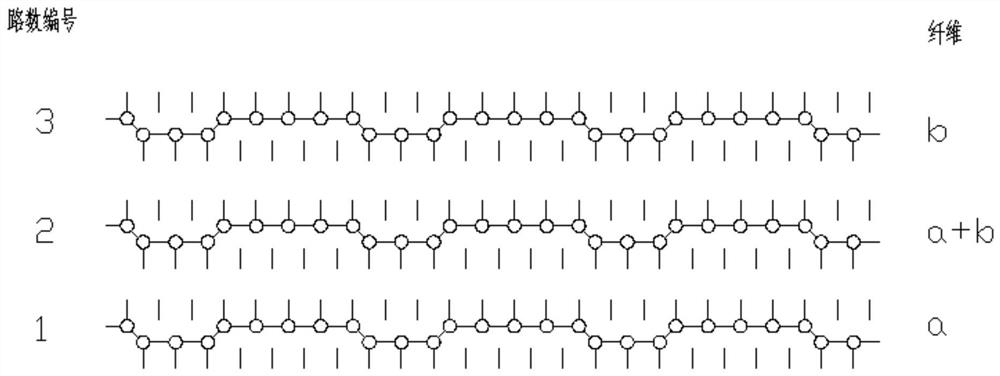

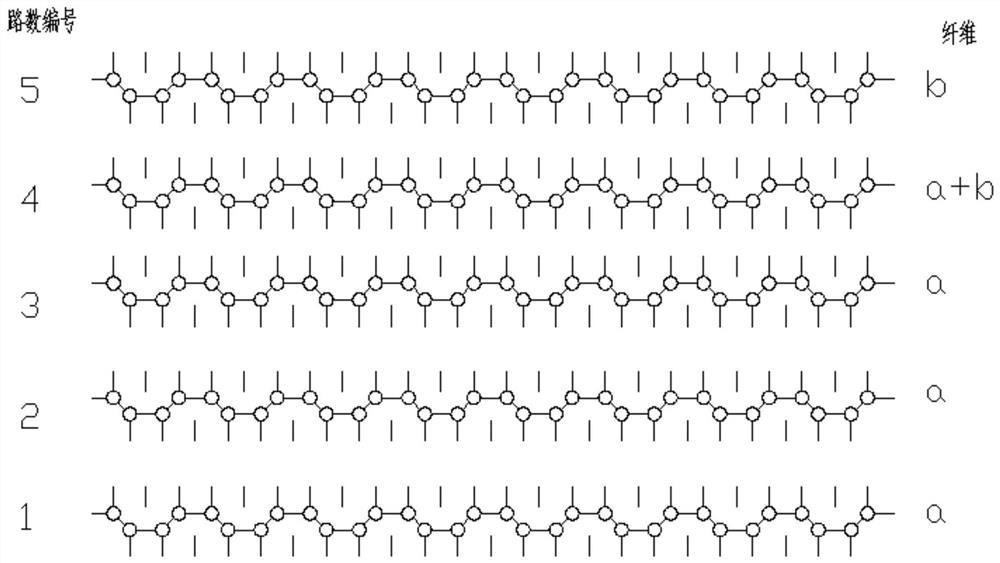

[0029] (3) Knitting back: The knitting machine is configured to have a number of dials and needle cylinders for upper and lower needles respectively. The upper and lower needles rise to move the old loop...

Embodiment 2

[0036] A static elimination processing method for wool knitted fabrics, the method is as follows:

[0037] (1) Pretreatment: soak the wool yarn in an antistatic solution and then dry it for pretreatment;

[0038] The wool mass percentage content of the wool yarn is 55%, and the antistatic solution is composed of dihydrogenated tallow dimethyl ammonium chloride, isomeric tridecyl alcohol polyoxyethylene ether, fatty alcohol ether phosphate, phenol ether Phosphate ester and water are composed in a mass ratio of 4:3:5:1:112, the soaking time is 22 minutes, the soaking temperature is 48°C, the drying temperature is 120°C, and the drying time is 60 minutes.

[0039] (2) Yarn feeding: the wool yarn and conductive fiber are sent to the loop knitting area of the knitting machine;

[0040] (3) Knitting back: The knitting machine is configured to have a number of dials and cylinders for upper and lower needles respectively. The upper and lower needles rise to move the old loops from ...

Embodiment 3

[0047]A static elimination processing method for wool knitted fabrics, the method is as follows:

[0048] (1) Pretreatment: soak the wool yarn in an antistatic solution and then dry it for pretreatment;

[0049] The wool mass percentage content of the wool yarn is 23%, and the antistatic solution is composed of dihydrogenated tallow dimethyl ammonium chloride, isomeric tridecyl alcohol polyoxyethylene ether, fatty alcohol ether phosphate, phenol ether Phosphate ester and water are composed according to the mass ratio of 4:3:5:1:128, the soaking time is 28 minutes, the soaking temperature is 43°C, the drying temperature is 116°C, and the drying time is 45 minutes.

[0050] (2) Yarn feeding: the wool yarn and conductive fiber are sent to the loop knitting area of the knitting machine;

[0051] (3) Knitting back: The knitting machine is configured to have a number of dials and needle cylinders for upper and lower needles respectively. The upper and lower needles rise to move t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com