Thyristor valve section and crimping method thereof

A thyristor valve and thyristor technology, which is applied in the direction of output power conversion devices, electrical components, electric solid devices, etc., can solve the problems that the center of the radiator cannot be guaranteed to be in the same straight line, the pressure of the thyristor is uneven, and the valve section is crimped unstable. Achieve the effect of providing reliability and stability, eliminating internal stress and improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 1. Thyristor valve section

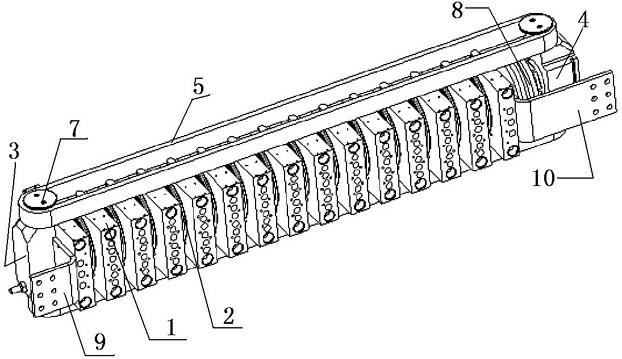

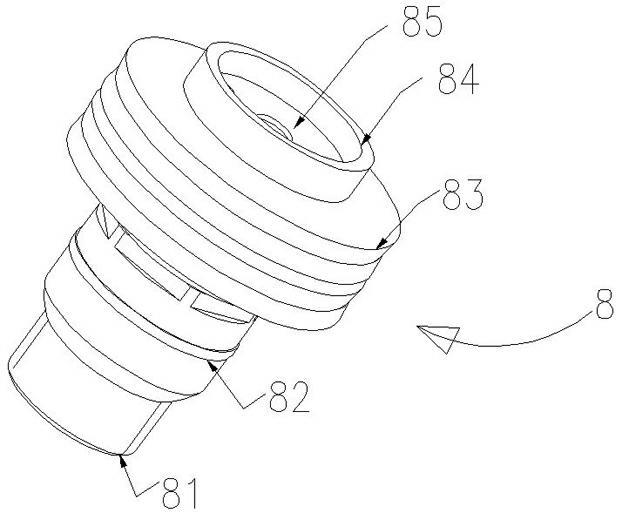

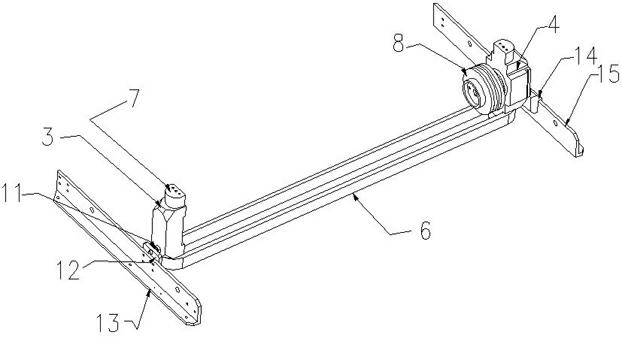

[0020] Thyristor valve section of the present invention such as figure 1 As shown, the valve section includes a valve group composed of alternately arranged water-cooled radiators 1 and thyristors 2 and a frame for installing the valve group. The upper and lower ends of the left end plate 3 and the right end plate 4 of the valve section are respectively provided with limit bolts 7, and the upper clamping ring 5 The two ends of the lower clamping ring 6 are clamped on the upper limit bolts of the left and right end plates of the valve section, and the two ends of the lower clamping ring 6 are clamped on the lower limit bolts of the left and right end plates of the valve section. Spring top pressure device 8, such as figure 2 As shown, the disc spring pressing device 8 is composed of a stainless steel bushing 81, a lock nut 82, a disc spring 83, a stainless steel retaining ring 84 and a stainless steel baffle 85, and the lock nut 82 is scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com