Production method of high-frequency four-layer circuit board

A manufacturing method and circuit board technology, applied in the direction of multi-layer circuit manufacturing, etc., to achieve the effect of solving edge burrs, stable performance, and improving manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

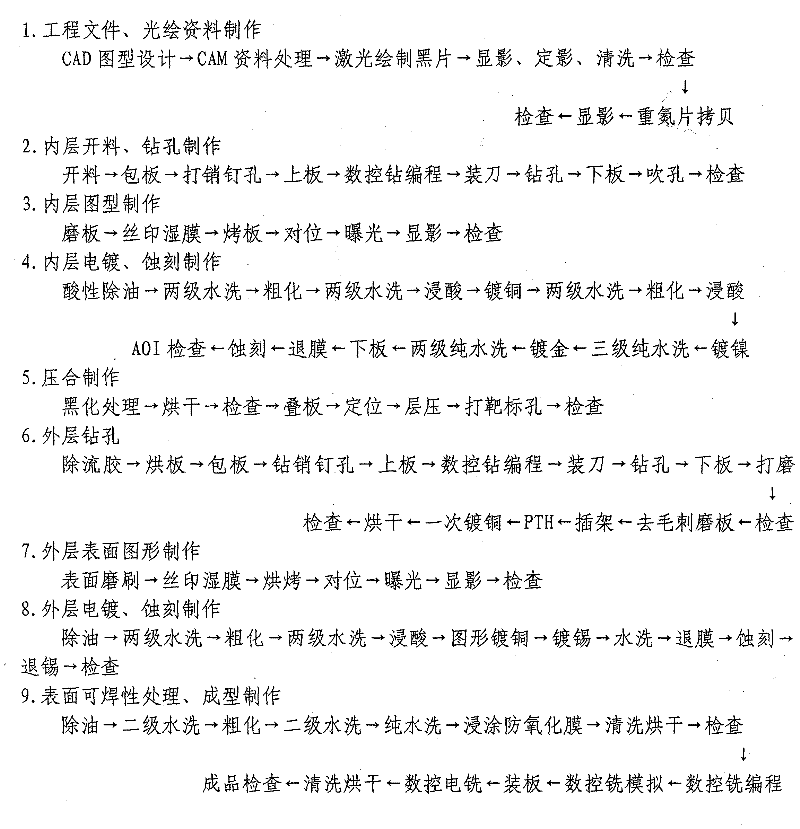

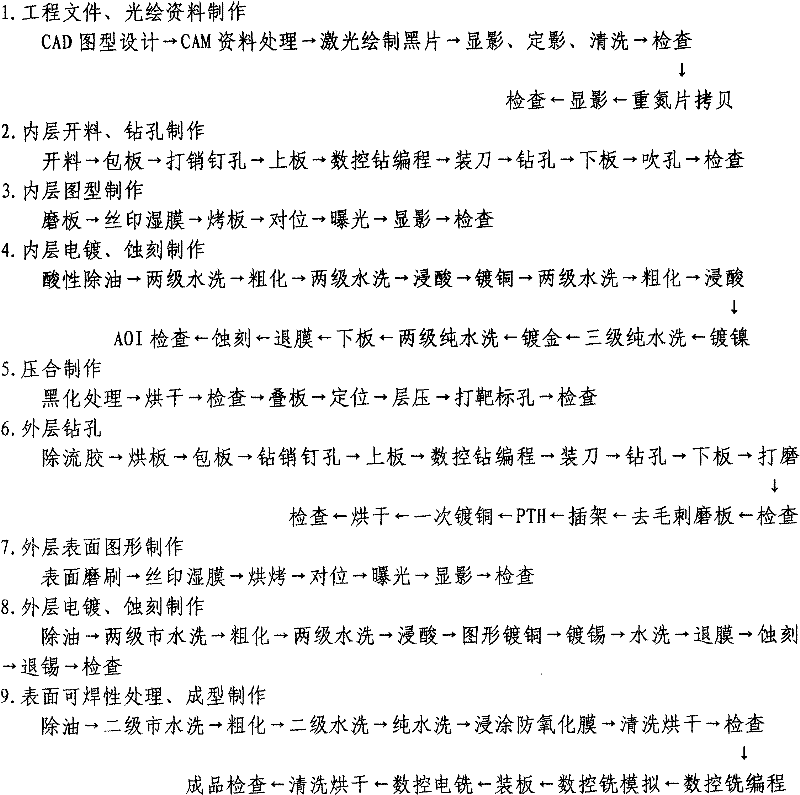

[0008] exist figure 1 Among them, the present invention is a method for manufacturing a high-frequency four-layer circuit board, which includes the following steps: Step 1, making engineering and light-painting materials: firstly, graphic design is carried out on the template, and then the designed graphics are carried out according to the production process parameters Process the engineering documents to make them meet the requirements of production and processing, then make imposition of the processed documents, and use a high-precision laser photo-painting machine with a resolution of 20240dpi to make black negatives of L1, L2, L3, and L4 layers, which is good for photo-painting Rinse, develop, fix, clean, and air-dry the negatives; then use a 200-fold magnifying glass to check the negatives and check the drawn negatives, and finally use a 3KW exposure machine to copy the diazo film based on the checked negatives. And check the copied diazo tablets. Step 2, the production ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com