Manufacturing method for flame-resistant impact resistant ABS (acrylonitrile-butadiene-styrene) composite material

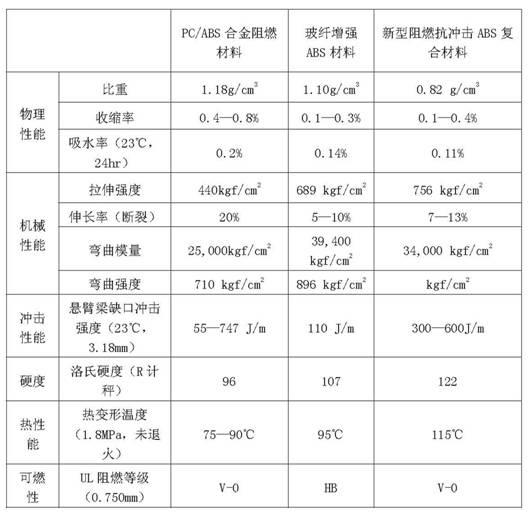

A composite material and a manufacturing method technology, applied in the field of manufacturing flame-retardant and impact-resistant ABS composite materials, can solve the problems of decreased surface finish, heavy quality and high cost, achieve simple and continuous production process, improve production efficiency and excellent product performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The manufacture method of flame-retardant impact-resistant ABS composite material of the present invention, its processing step is as follows:

[0012] (1) First put 20-40 parts by weight of glass fibers and 10-14 parts by weight of hollow glass microspheres into a solid mixer, and directly spray the silane coupling agent solution on the glass fibers and hollow glass microspheres and stir, Use high rotational speed in order to achieve good dispersion effect. After stirring for 10-30 minutes, dry at 120°C for about 2 hours;

[0013] (2) Fully mix the processed glass fibers and glass beads with 100 parts by weight of ABS resin, 50-80 parts by weight of PC resin, and 2-4 parts by weight of lubricant, and then pass through the feeding device Feed into the twin-screw extruder, under the heating, shearing and mixing of the screw, the material is fully melted, and then extruded, drawn, cooled and pelletized to be the finished product.

[0014] The aspect ratio of the twin-sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com