Oil-in-water drilling fluid suitable for different kinds of furnish preparation water and oils

The technology of oil-in-water drilling fluid and main emulsifier is applied in the field of oil-in-water drilling fluid, which can solve the problems of effective development of buried hill oil and gas reservoirs and difficult underbalanced drilling operations, complex geological conditions and high formation temperature, and achieves strong inhibition performance and anti-pollution ability, easy on-site operation, and simple handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

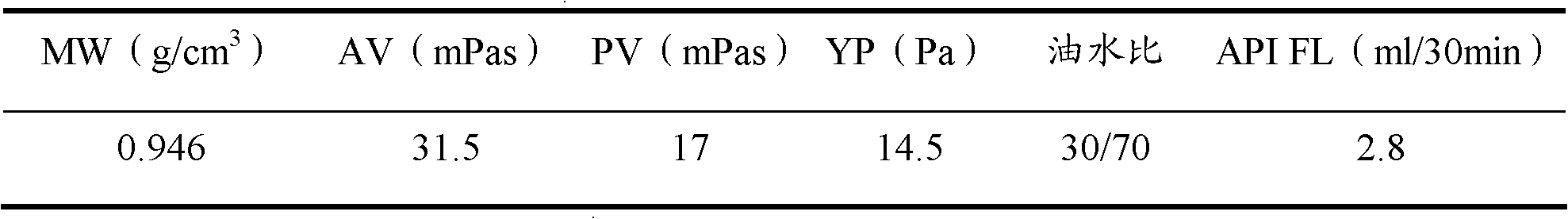

[0043] Measure 280ml of seawater into a high stirring cup, add 1.2g of caustic soda, stir at 10,000 rpm for 2 minutes, add 4g of supplementary milk, stir at high speed for 2 minutes, measure 120ml of gas oil and slowly add it to the cup, and stir at 10,000 rpm for high Stir for 10 minutes, add 10g of main milk, stir at 10,000 rpm for 20 minutes to make it fully emulsified, add 4g of fluid loss reducer, stir at 10,000 rpm for 10 minutes, add 2.4g of thickener, and stir at 10,000 rpm for 20 minutes, Form a stable white emulsion, the preparation is complete, and the measurement properties are as shown in Table 1:

[0044] Table 1 Example 1 prepares the performance of oil-in-water drilling fluid

[0045]

Embodiment 2

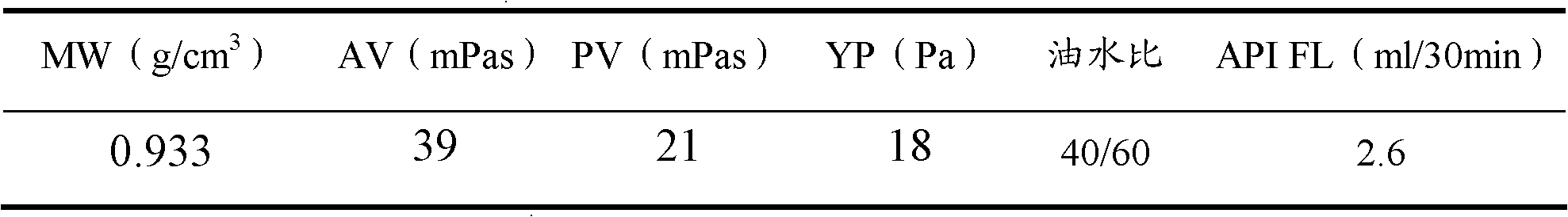

[0047] Measure 240ml of seawater into a high stirring cup, add 1.2g of caustic soda, stir at 10,000 rpm for 2 minutes, add 4g of supplementary milk, stir at high speed for 2 minutes, measure 160ml of white oil and slowly add it to the cup, stir at 10,000 rpm 10min, add 10g of main milk, stir at 10000 rpm for 20min to make it fully emulsified, add 4g fluid loss reducer, stir at 10000rpm for 10min, add 2.4g of thickener, stir at 10000rpm for 20min, and form Stable emulsion, the preparation is completed, and the measurement properties are as shown in Table 2:

[0048] The performance of table 2 embodiment 2 preparation oil-in-water drilling fluid

[0049]

Embodiment 3

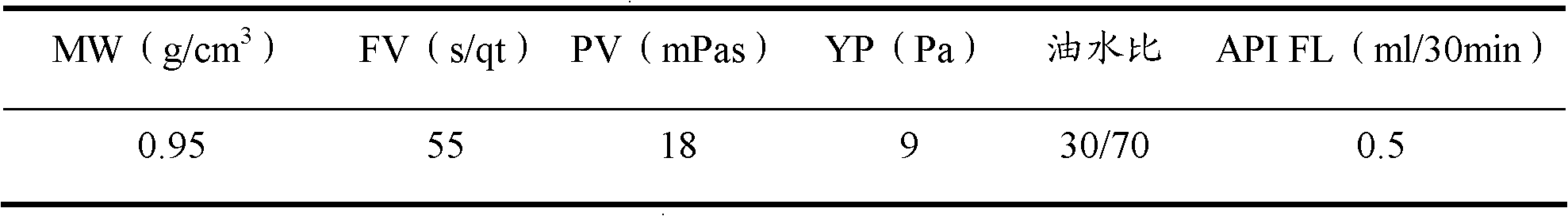

[0051] This patent is implemented in a well in the Bohai Oilfield. The implementation site is a drilling platform. Before drilling, 70m of oil-in-water drilling fluid is placed in each of the two mud pools. 3 , first add 49m in the mud pool 3 sea water and 21m 3 Gas to oil, then add 850kg PF-WOCOAT (secondary emulsifier) and 1400kgPF-WOEMUL (main emulsifier) through the addition funnel, stir thoroughly for 3 hours, then add 1300kgPF-WODFL (fluid loss reducer) and 250kgPF-WOVIS, and finally Stir again for 6 hours, the performance of measuring is as follows:

[0052] Table 3 Properties of newly prepared oil-in-water drilling fluid

[0053]

[0054] After spud drilling, use the configured oil-in-water drilling fluid to drill. During the drilling process, the drilling fluid has stable performance, strong anti-pollution ability, good performance and easy maintenance, which meets the requirements of the development of buried hill reservoirs in this block. The requirement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com