Deposited metal stripping agent and preparation method thereof

A technology for depositing metal and stripper, which is applied in the direction of metal material coating process, liquid chemical plating, coating, etc., can solve the problems of difficulty in plating solution, reduce the quality of plating on other parts, and uneconomical problems, and achieve low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

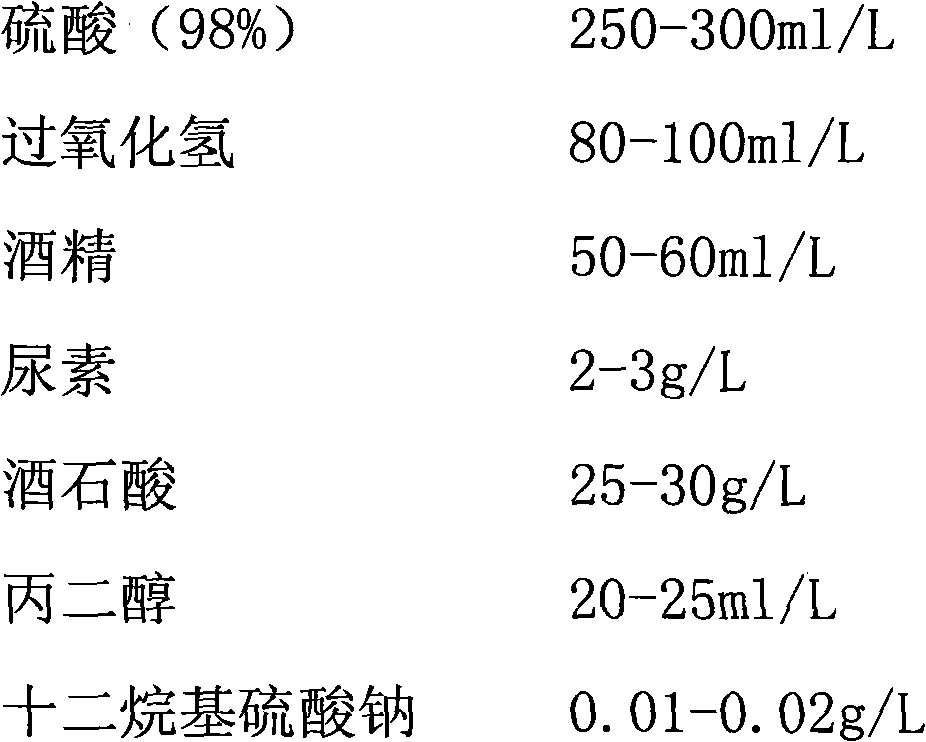

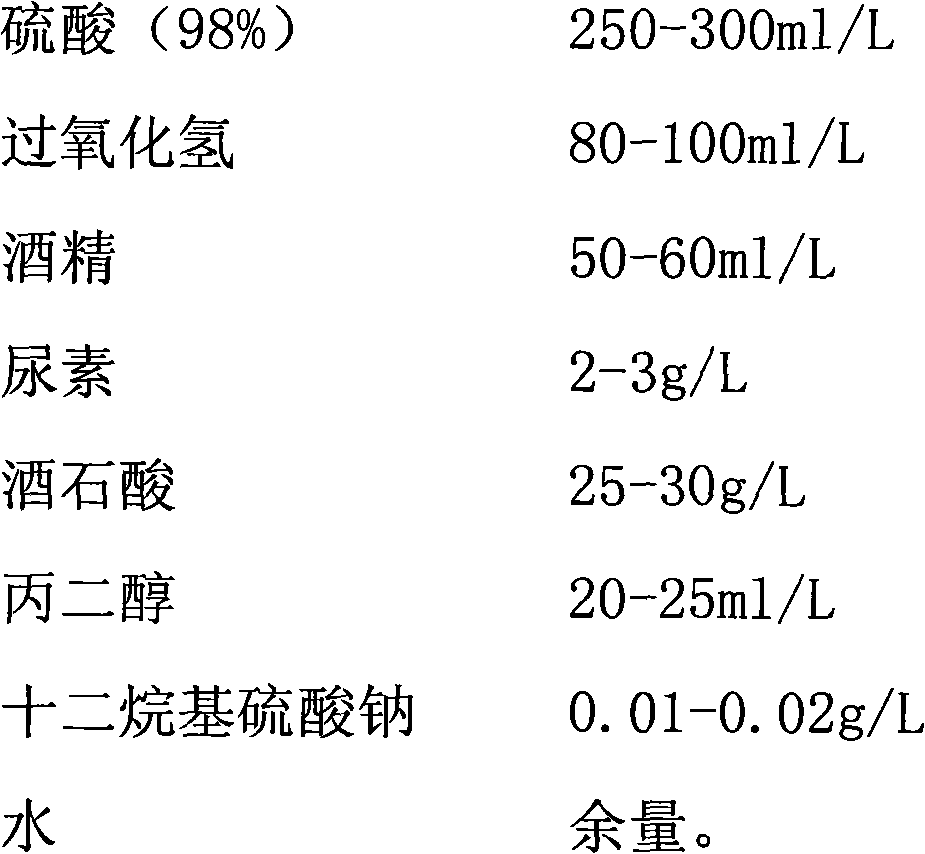

[0012] Deposited metal remover of the present invention is made up of following each component:

[0013]

[0014] The preparation method of the above-mentioned deposited metal remover is as follows: at normal temperature, add 1 / 2 tap water of the allocated volume in the container, slowly add concentrated sulfuric acid (98%) under continuous stirring, then add hydrogen peroxide, alcohol, urea , tartaric acid, propylene glycol and sodium lauryl sulfate, stirring continuously to dissolve it, adding the remainder of tap water, and stirring until the solution is homogeneous and transparent.

[0015] The method of using the above-mentioned deposited metal remover is as follows: heat the remover to 40-50°C, pour it into the plating tank, immerse the surface of the deposited metal, and stir continuously. When all the deposited metal is removed, pour it out and remove it. solution, cleaning the plating tank, the plating tank can be used for electroless plating again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com