Double-cavity thermal field of crystal silicon ingot casting furnace and control method thereof

A control method and ingot furnace technology, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problem that the solid-liquid interface cannot be continuously corrected, the crystal melting and crystal growth process time cannot be taken into account, and the crystal growth is controllable Insufficient performance and other problems, to achieve the effect of increasing process time and power consumption, easy installation and use, and increasing temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

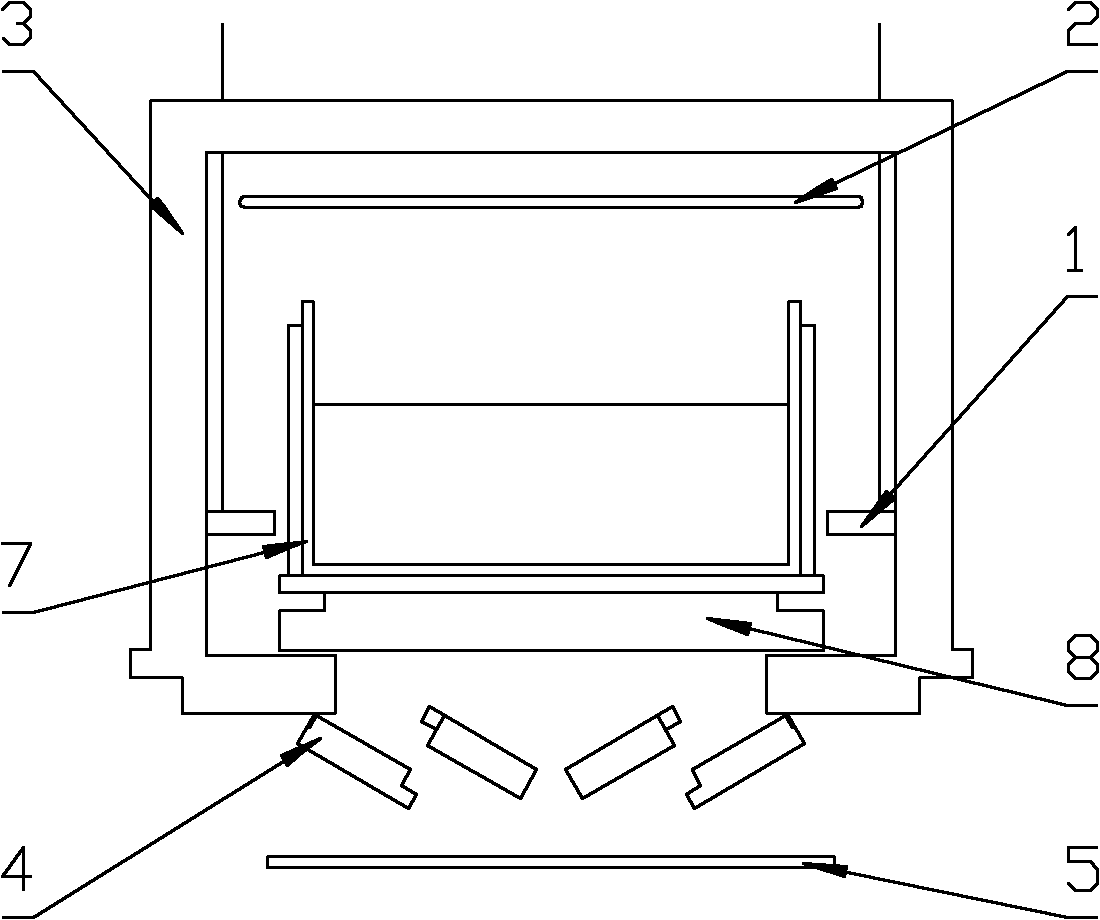

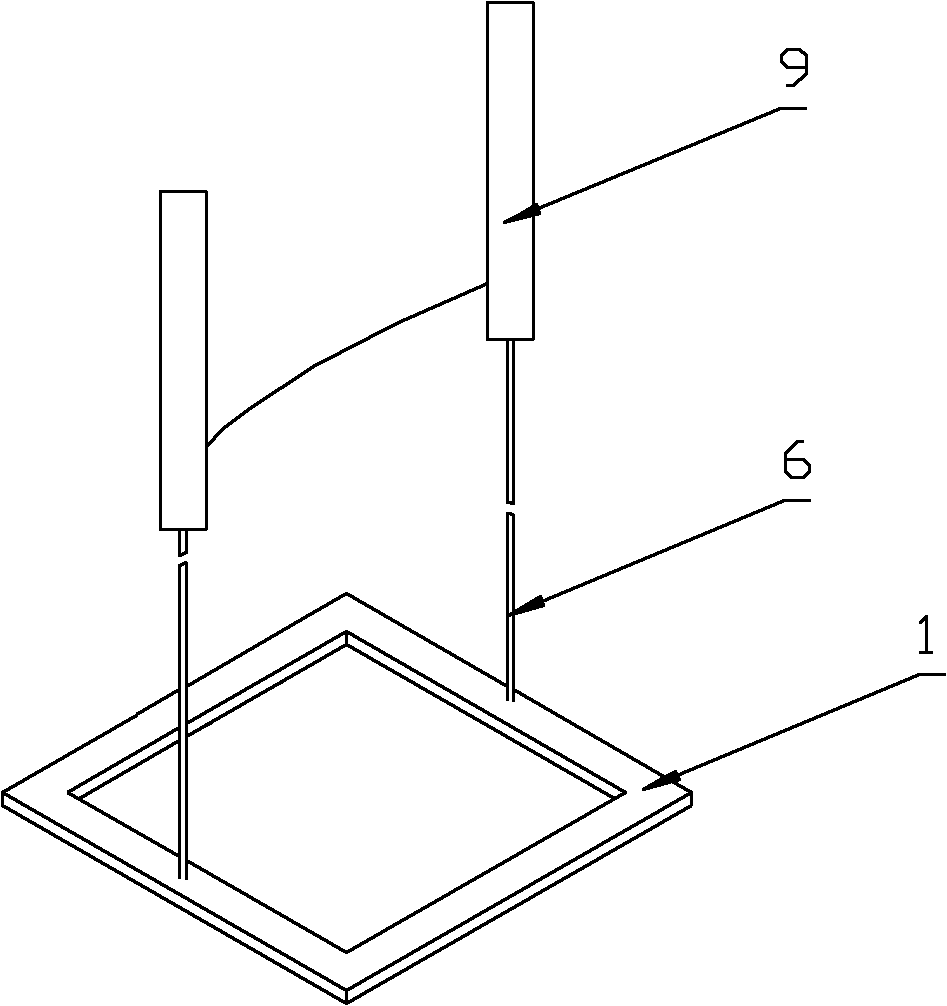

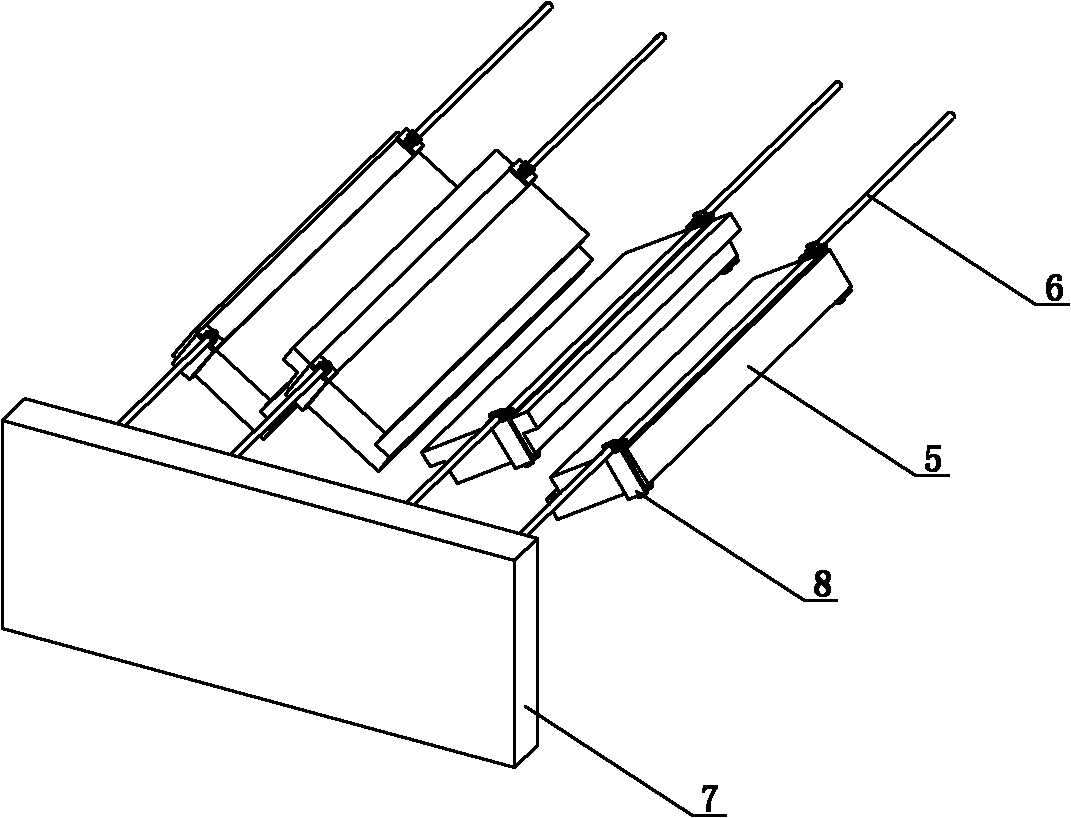

[0030] Such as figure 1 The shown double-chamber thermal field of a crystalline silicon ingot casting furnace consists of a thermal insulation cage 3, a single upper heater 2 arranged in the thermal insulation cage, a heat exchange table 8 for placing a crucible 7, and a heat exchange table and a heat insulation cage. The heat dissipation between the outside of the cage is composed of a water-cooled plate 5 under the heat-insulating cage, and a heat-exchanging platform 8 is placed in the heat-insulating cage 3. The inner wall of the heat-insulating cage 3 is provided with a circle of friction on it and can be moved along the The dividing plate 1 of its lifting. The partition is made of heat insulating material. The partition 1 is located between the inner wall of the heat insulation cage and the outer wall of the heat exchange platform. Suspenders 6 are fixed on the partitions on both sides of the heat exchange platform. The upper ends of the suspension rods pass through the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com