Flexible-transmission composite balanced oil sucking machine

A flexible transmission and pumping unit technology, applied in transmission devices, mechanical equipment, mining fluids, etc., can solve the problems of large amount of steel and cement, many energy transmission links, low system efficiency, etc., to reduce volume, improve efficiency, Smooth running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

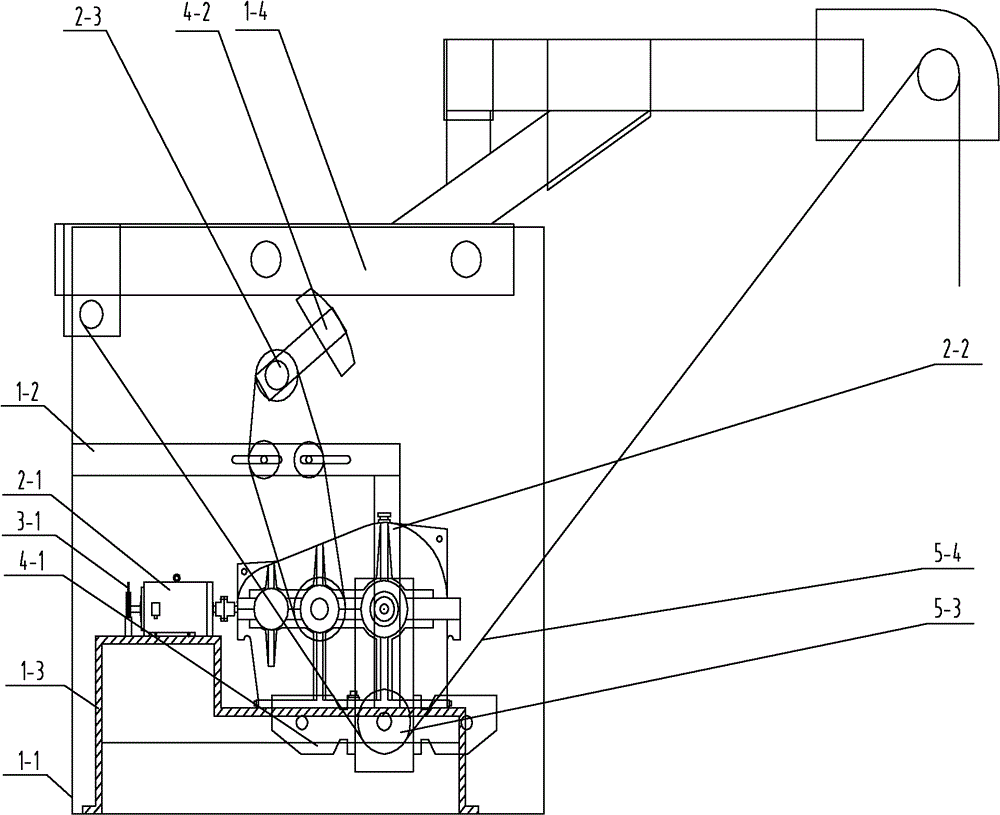

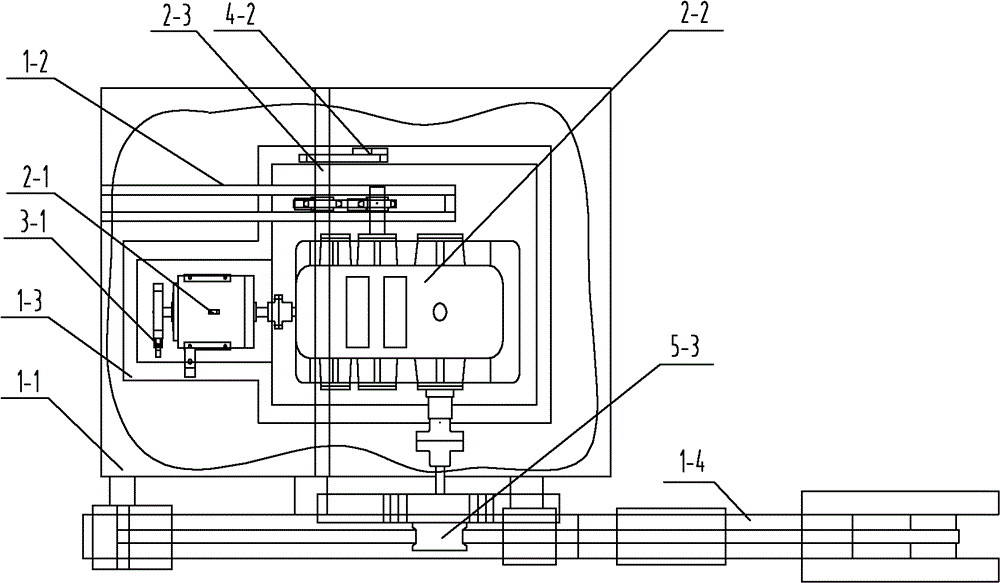

[0031] Depend on figure 1 combine figure 2 As shown, the flexible transmission compound balanced pumping unit includes a frame base system, a power transmission system, a brake system, a balance system and a reversing system.

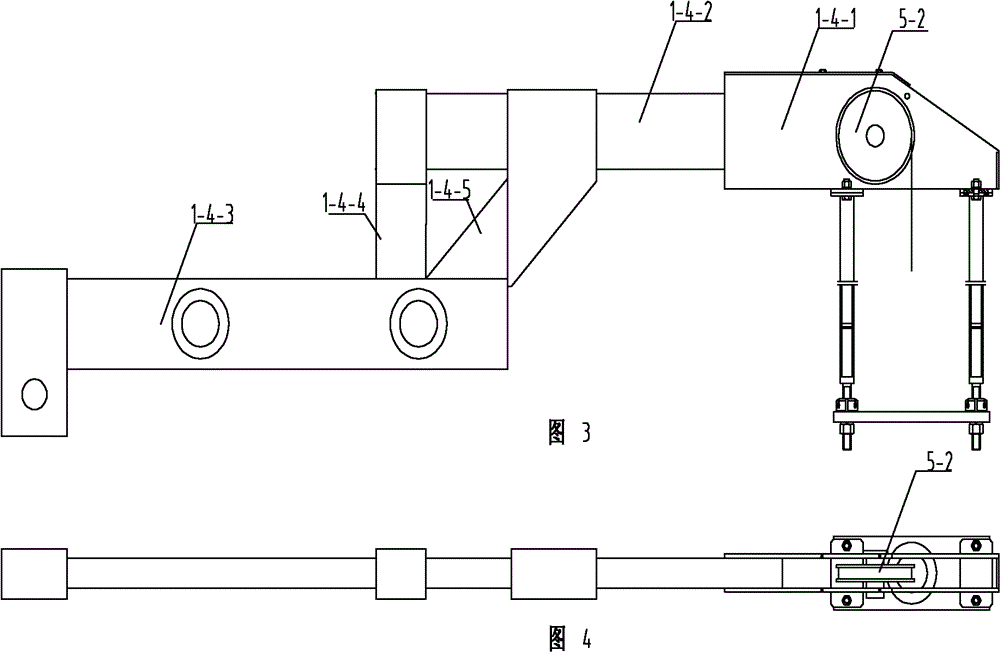

[0032] The frame base system includes a box body 1-1, a frame 1-2, a base 1-3 and a wellhead support 1-4; image 3 combine Figure 4 Shown: wellhead support 1-4, including support head 1-4-1 and upper and lower beams, wherein support head 1-4-1 and upper beam 1-4-2 are welded and fixed; lower beam 1-4-3 passes through The column is welded and fixed on the upper end of the box body 1-1; the lower beam 1-4-3 is also welded and fixed on the straight support beam 1-4-4 and the inclined support beam 1-4-5, and the straight and inclined support beams are welded with inverted U Shaped sleeve, the upper beam 1-4-2 passes through the inverted U-shaped s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com