Pipe-cavity integrated disc solar heat receiver

A solar thermal and receiver technology, applied in solar thermal collectors, solar thermal collectors using working fluid, solar thermal energy, etc., can solve local damage or air leakage, extremely high material requirements, difficult to guarantee air tightness, etc. problems, to achieve the effect of uniform circumferential temperature, high heat absorption rate, and uniform gas distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

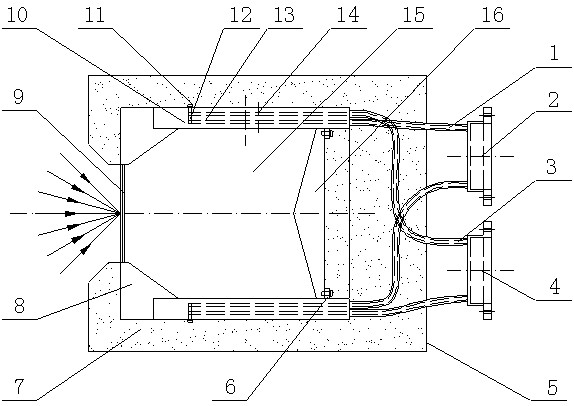

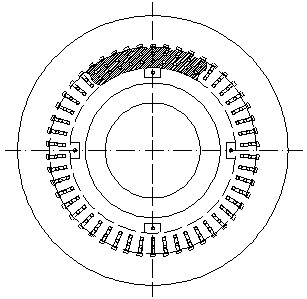

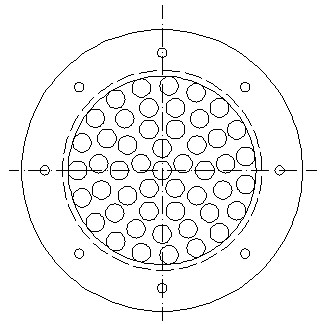

[0020] Such as figure 1 As shown, the lumen-integrated dish-type solar heat receiver includes an inner ventilation pipe 1, a first gas distribution / collection cover 2, an outer ventilation pipe 3, a second gas distribution and collection cover 4, an aluminum alloy shell 5, and a fixed connection. Plate 6, high temperature heat insulation layer 7, annular diffuse reflector 8, high temperature resistant quartz glass 9, cylindrical cavity 10, screw 11, communication hole 12, inner ring flow channel 13, outer ring flow channel 14, heat absorption cavity 15 and diffuser Reflecting cone 16; annular diffuse reflector 8 is tightly connected to the top of cylindrical cavity 10, and the bottom of cylindrical cavity 10 is provided with a diffuse reflecting cone 16, and diffuse reflecting cone 16 is fixed on four connection fixing plates 6 by screws Above, the four connecting and fixing plates 6 are evenly welded to the inner wall of the cylindrical cavity 10 along the circumferential dir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com