Method for testing rated working temperature of component battery under non-standard environment condition

A technology for rated work and testing components, applied to thermometers, thermometers with directly heat-sensitive electric/magnetic components, measuring devices, etc., can solve problems such as inability to accurately reflect the rated working temperature of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] A test square array is designed as an n×n array, and test components are installed in the middle, and the installation of the test components must be detachable. When n is an odd number, the installation position of the test component is as follows figure 1 shown. When n is an even number, the installation position of the test component is as follows figure 2 shown.

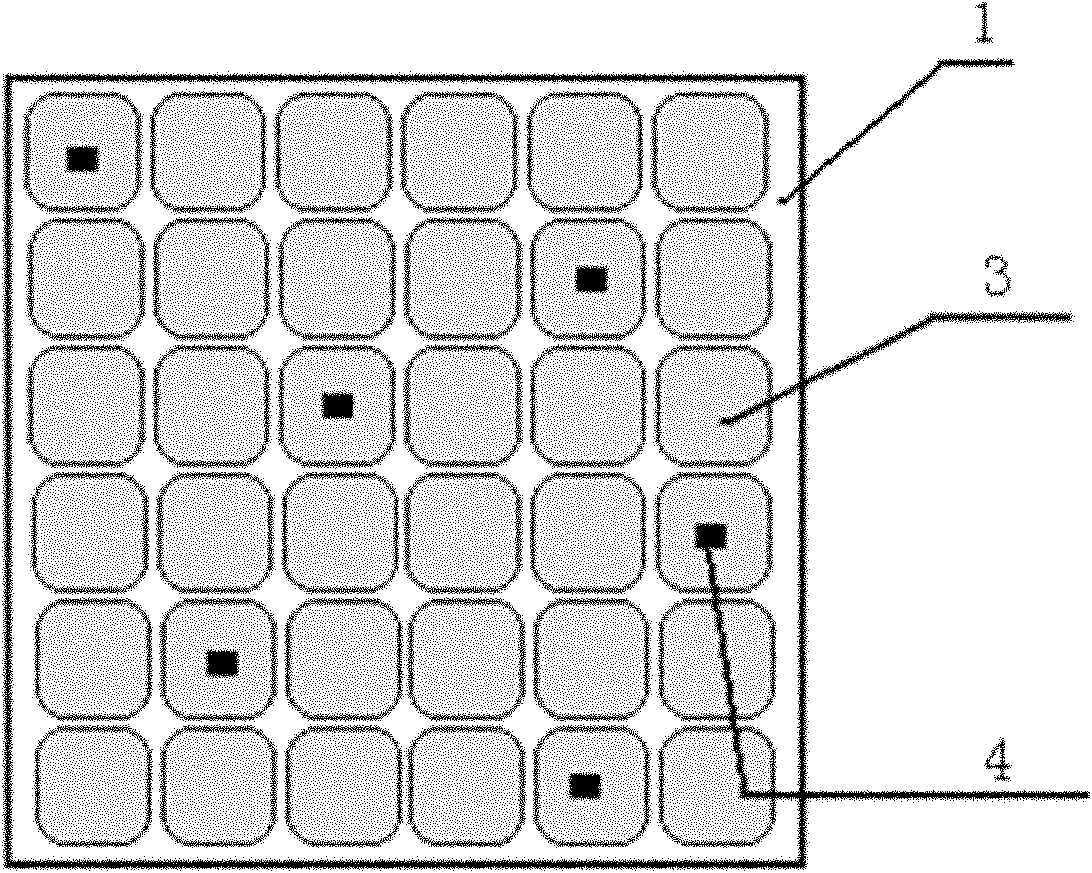

[0045] Select a number of representative test points in the test component, and set a thermocouple to measure the temperature at the test point. The location requirement of the thermocouple is mainly based on the idea that the location of the test point must be representative and can fully represent the temperature of the battery in other locations of the module. 6×6 crystalline silicon solar cell module, press on the back figure 1 Arrange thermocouple points as shown; make a sample with a length or width of 0.5m ~ 0.8m for a thin-film solar cell module. During the production process, preset at least ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com