Metal suction end for assembling laser diode

A technology of laser diodes and metals, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of easy aging of rubber materials, difficulty in making heads, short service life, etc., achieve long service life, reduce surface pressure, Good observation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

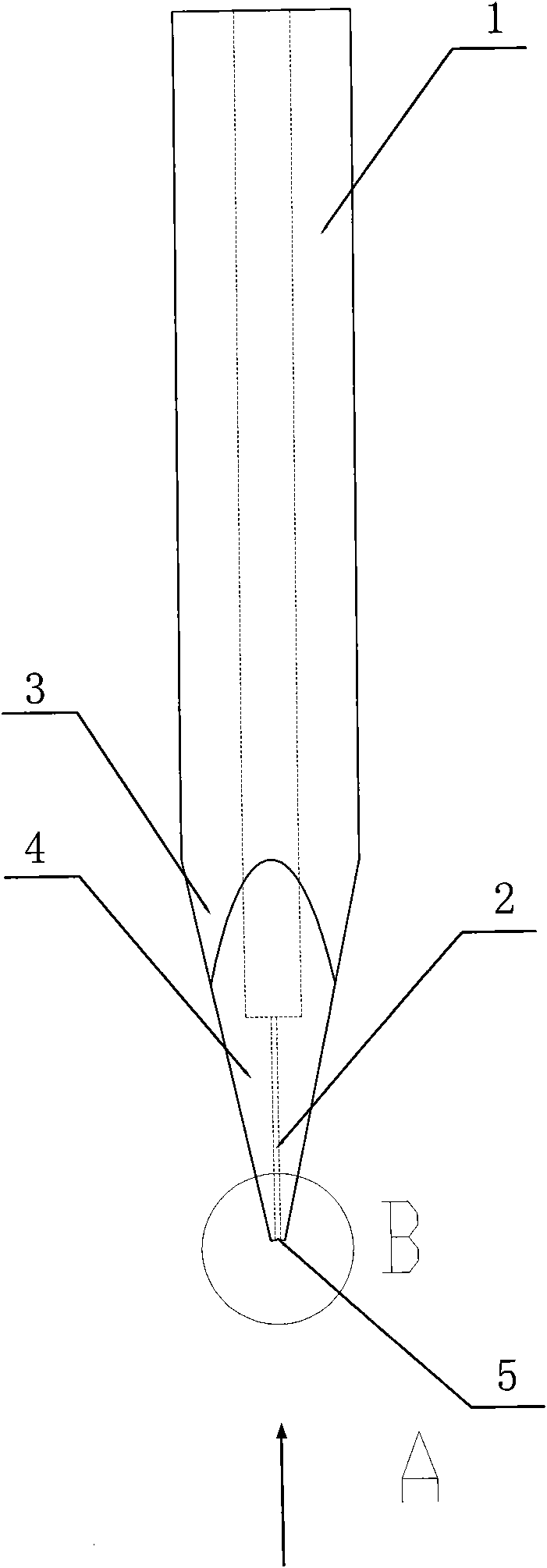

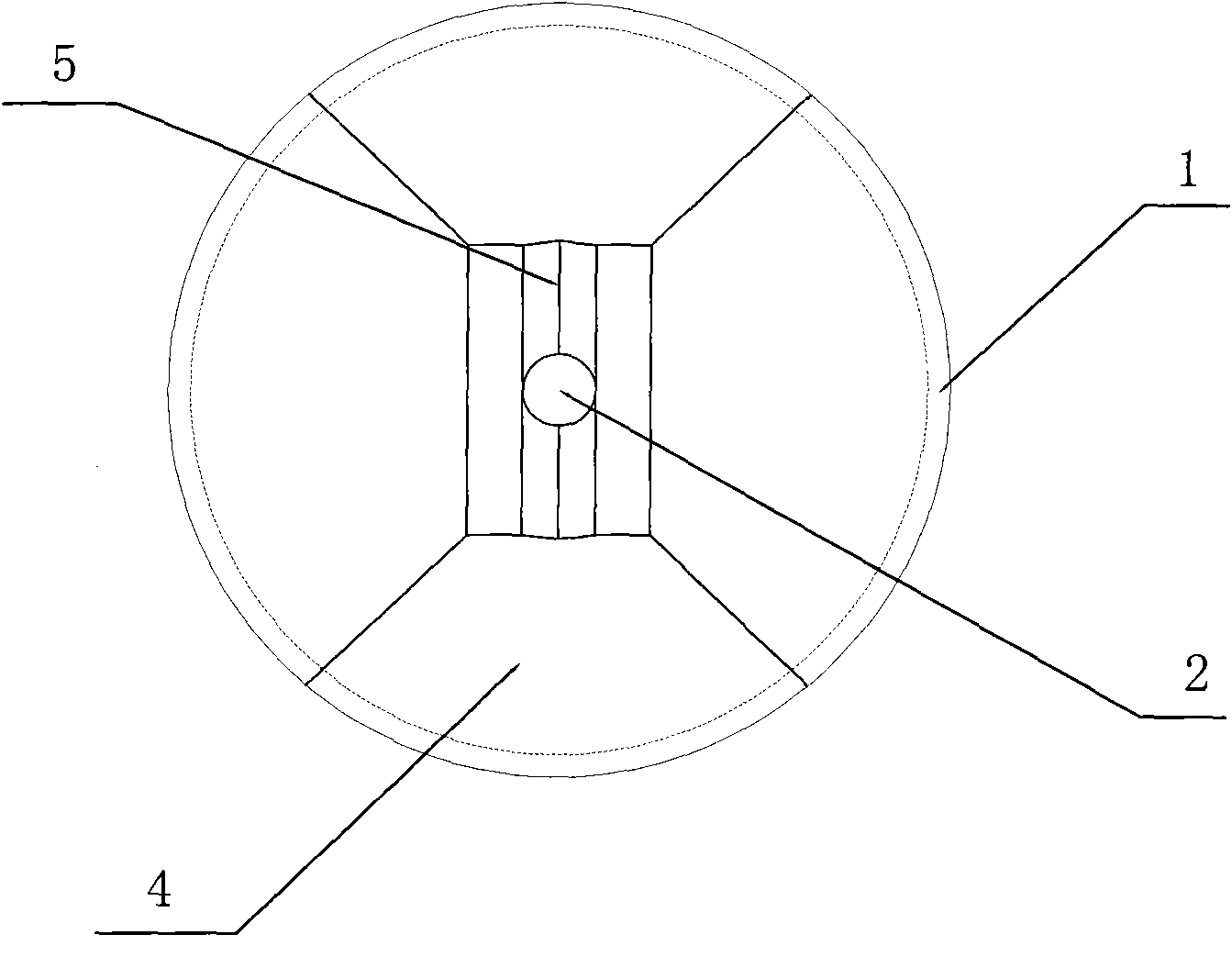

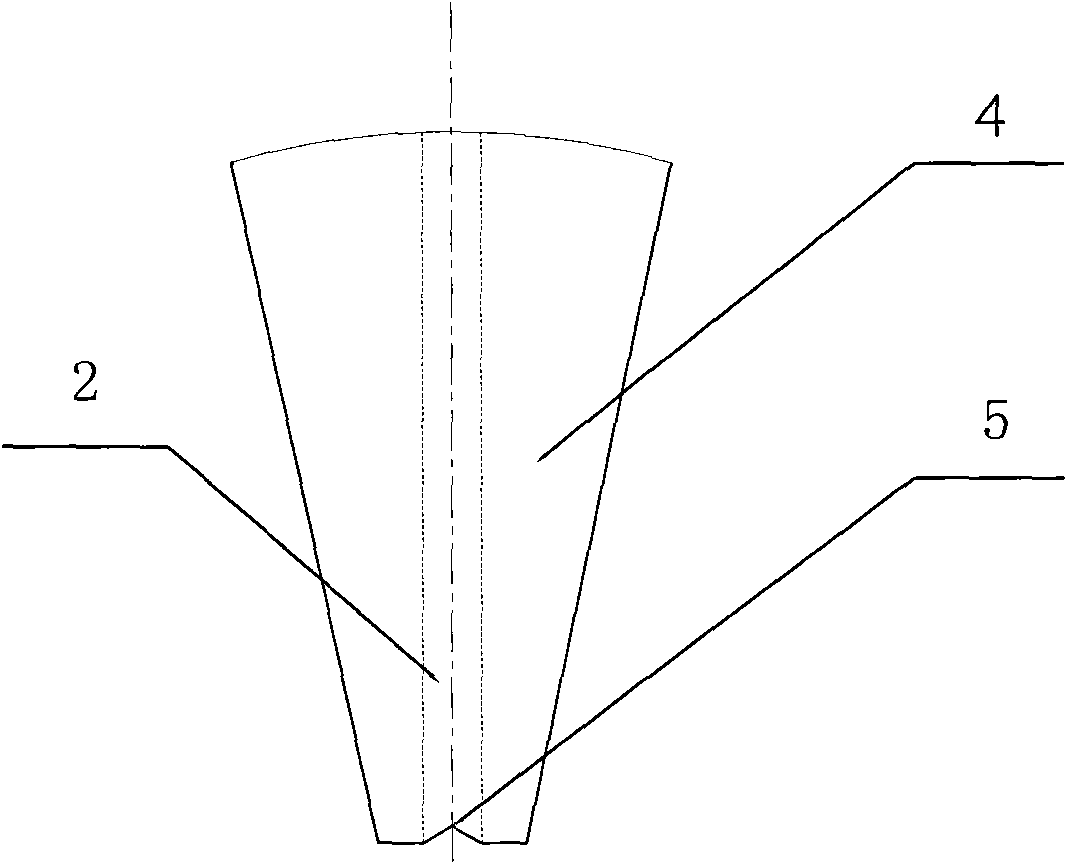

[0011] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 , 2 Shown in , 3: the same as the prior art, there is a metal cylinder 1, there is a suction hole 2 at the axis of the metal cylinder 1, and the front end of the metal cylinder 1 is a frustum-shaped head 3, which is different from the prior art It is a metal with an integrated structure of the frustum-shaped head 3 and the metal cylinder 1. On the frustum-shaped head 3, there are two wedge surfaces 4 arranged symmetrically along the axis. Front V-groove 5. In order to further improve the absorption performance, the opening angle of the V-shaped groove 5 is 120°-150°. The metal cylinder 1 and the frustum-shaped head 3 are preferably made of tungsten steel, which can withstand the temperature requirement of 300°C to 800°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com