Insulation process of motor stator punching sheet for electric vehicle

A motor stator and stator punching technology, which is applied to electric vehicles, motors, laying solid insulation, etc., can solve problems such as high labor costs, friction of rotors, and exposed bamboo sticks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

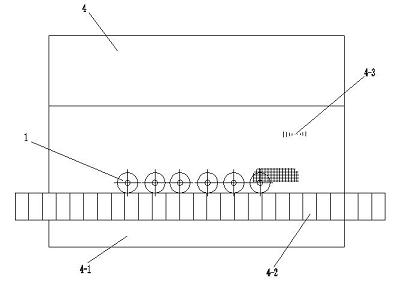

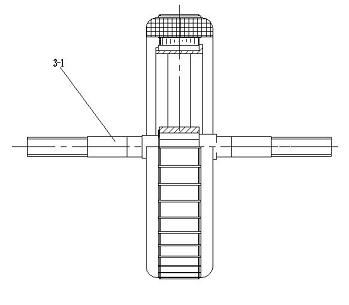

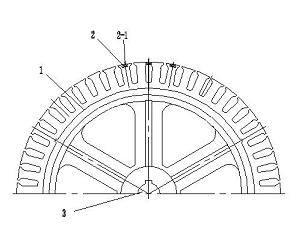

[0018] The following embodiments are given in conjunction with the accompanying drawings to further describe in detail the insulation process of the electric motor stator punching sheet of the present invention.

[0019] see figure 1 , 2 , 3, 4, an insulation process for electric vehicle motor stator punching, its innovative points are:

[0020] a. Including the surface treatment, masking, preheating and dip-coating curing of the motor stator punching sheet 1 in sequence;

[0021] b. The masking is the process of protecting the parts that do not need to be coated with an insulating layer after the surface treatment of the motor stator punching sheet 1, including installing and connecting the rotating shaft protection tooling 3 at the shaft hole 3 of the motor stator punching sheet 1. 1. A Hall slot protection tool 2-1 is installed in the Hall slot 2 of the motor stator punch 1, and the Hall slot protection tool 2-1 includes a protection block 2- corresponding to the shape of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com