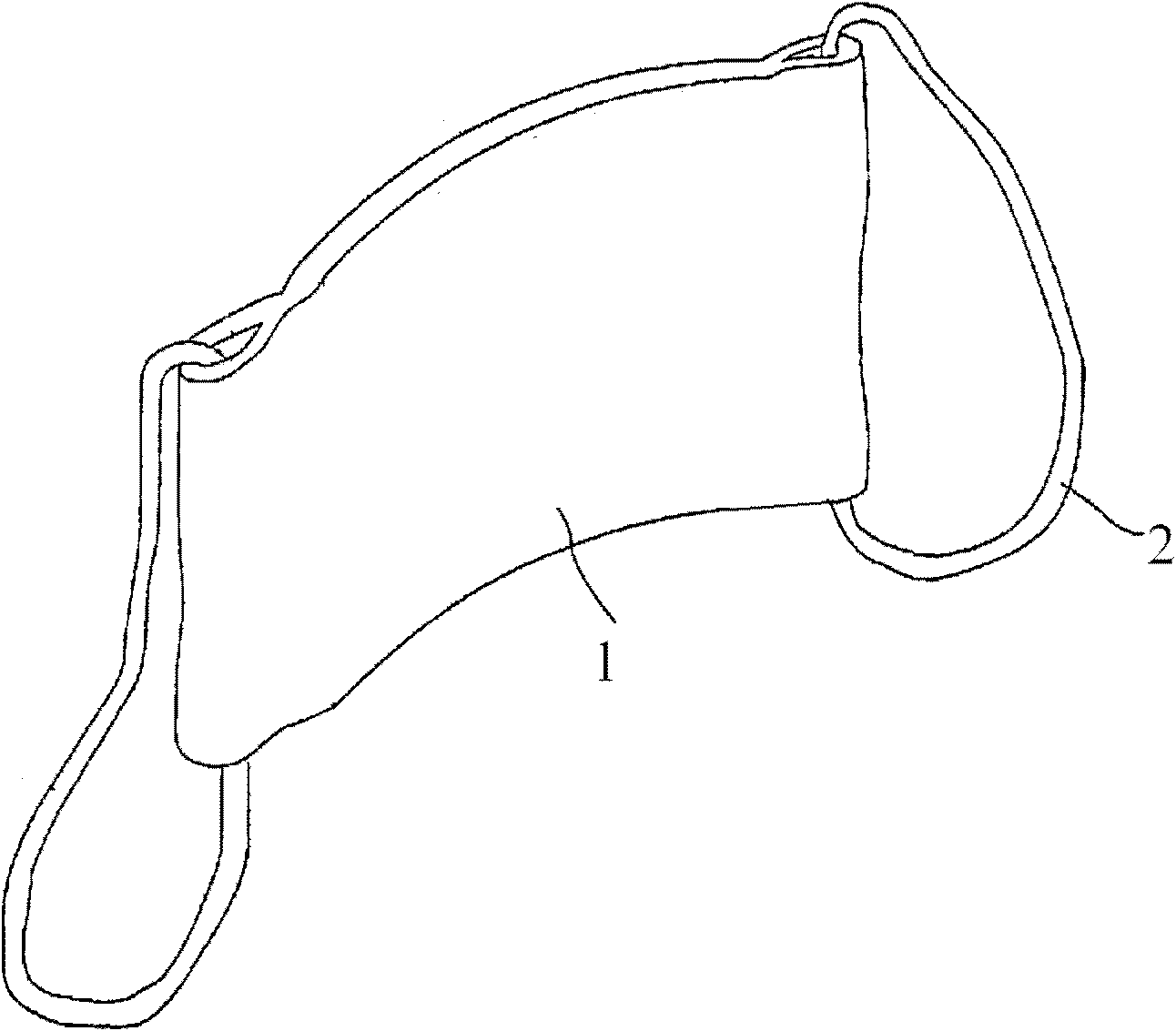

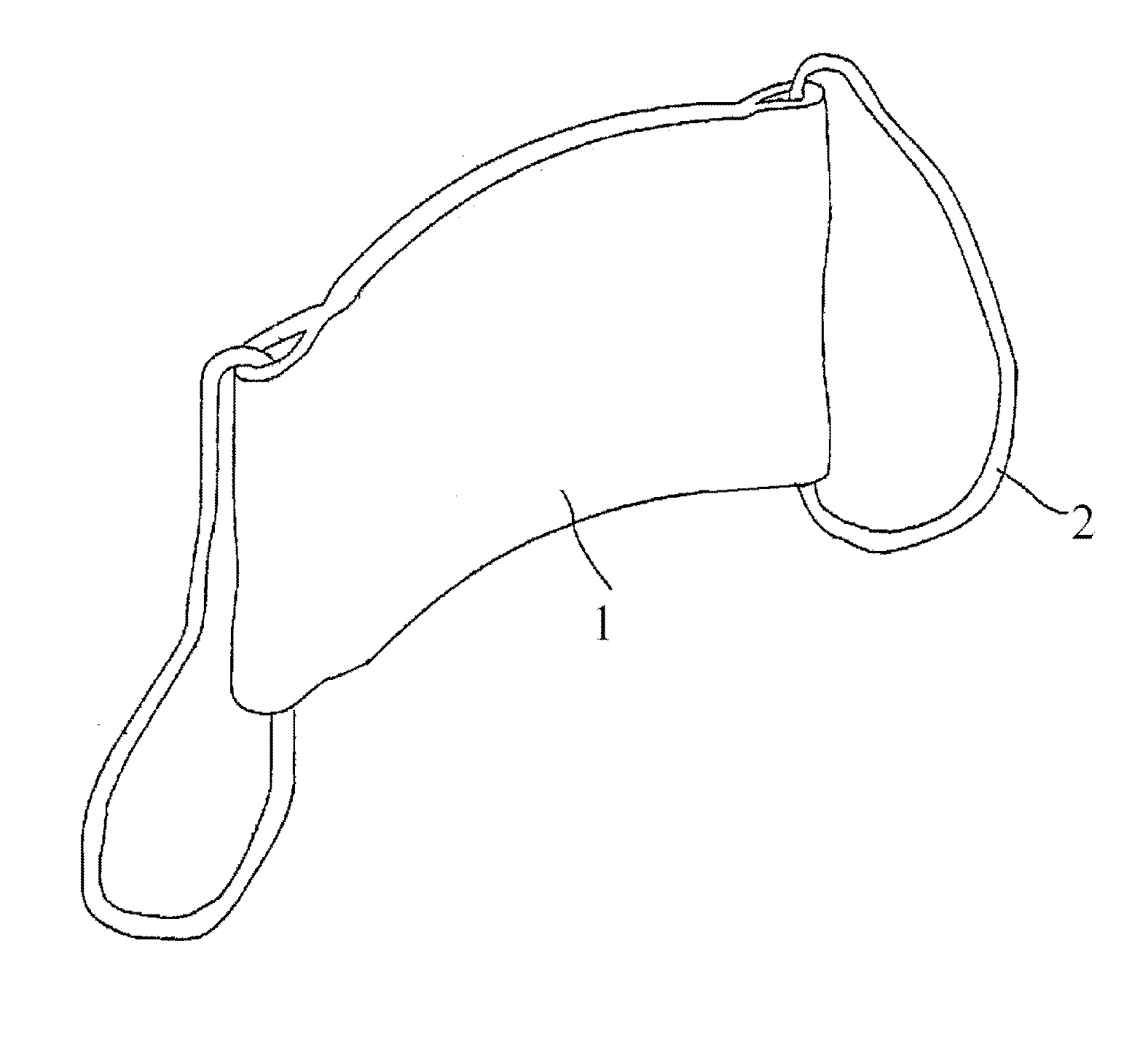

Protective facial mask containing nano silver and chitosan and production method of protective facial mask

A technology of chitosan and nano-silver, which is applied in the field of hygiene product preparation, can solve problems such as single function, and achieve the effect of comfortable wearing, suitable for large-scale industrial production, and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Weigh 0.5 g of chitosan and dissolve it in 50 ml of 1% acetic acid solution to prepare a 1% chitosan solution with a mass concentration.

[0025] (2) Weigh 0.085g silver nitrate (AgNO 3 ) was dissolved in 50ml chitosan solution, and after fully stirring, AgNO with a concentration of 0.01M was formed 3 - Chitosan solution, let stand for 6-12 hours.

[0026] (3) Soak double-layer absorbent cotton gauze in AgNO 3 - in the chitosan mixed solution, pre-freeze at -20° C. after 4 hours, and freeze-dry to prepare a double-layer degreasing cotton gauze containing nano-silver and chitosan.

[0027] (4) Soak the double-layer degreasing cotton gauze containing nano-silver and chitosan in 2.5% glutaraldehyde solution, freeze-dry after 0.5 hour.

[0028] (5) Take out the degreasing cotton gauze treated in step (4), soak it in a sodium borohydride solution with a mass concentration of 3% for 6 hours, remove residual glutaraldehyde small molecules, and simultaneously add AgNO 3...

Embodiment 2

[0031] (1) The chitosan of taking 1g is dissolved in the acetic acid solution of 50ml 1%, prepares the chitosan solution that mass concentration is 2%.

[0032] (2) Weigh 3.4g silver nitrate (AgNO 3 ) was dissolved in 50ml chitosan solution, and after fully stirring, AgNO with a concentration of 0.4M was formed 3 - Chitosan solution, let stand for 6-12 hours.

[0033] (3) Soak double-layer absorbent cotton gauze in AgNO 3 - in the chitosan mixed solution, pre-freeze at -25°C after 8 hours, and freeze-dry to prepare a double-layer degreasing cotton gauze containing nano-silver and chitosan.

[0034] (4) Soak the double-layer degreasing cotton gauze containing nano-silver and chitosan in 2.5% glutaraldehyde solution, freeze-dry after 1 hour.

[0035] (5) Take out the degreasing cotton gauze treated in step (4), soak it in a sodium borohydride solution with a mass concentration of 3% for 7 hours, remove residual glutaraldehyde small molecules, and simultaneously add AgNO 3 Re...

Embodiment 3

[0038] (1) Weigh 1.5g of chitosan and dissolve it in 50ml of 1% acetic acid solution to prepare a chitosan solution with a mass concentration of 3%.

[0039] (2) Weigh 0.85g silver nitrate (AgNO 3 ) was dissolved in 50ml chitosan solution, and after fully stirring, AgNO with a concentration of 0.1M was formed 3 - Chitosan solution, let stand for 6-12 hours.

[0040] (3) Soak double-layer absorbent cotton gauze in AgNO 3 - in the chitosan mixed solution, pre-freeze at -30° C. after 12 hours, and freeze-dry to prepare a double-layer degreasing cotton gauze containing nano-silver and chitosan.

[0041] (4) Soak the double-layer degreasing cotton gauze containing nano-silver and chitosan in 2.5% glutaraldehyde solution, and freeze-dry after 2 hours.

[0042] (5) Take out the degreasing cotton gauze treated in step (4), soak it in a sodium borohydride solution with a mass concentration of 3% for 8 hours, remove residual glutaraldehyde small molecules, and simultaneously add AgNO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com