Process for purifying desulfurization solvent in flue gas desulfurization of solvent circulating absorption method

A solvent circulation and purification process technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of reducing the desulfurization efficiency and regeneration effect of desulfurization solvents, threatening the normal operation of desulfurization devices, and equipment failures, etc. Stability, easy operation, high purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

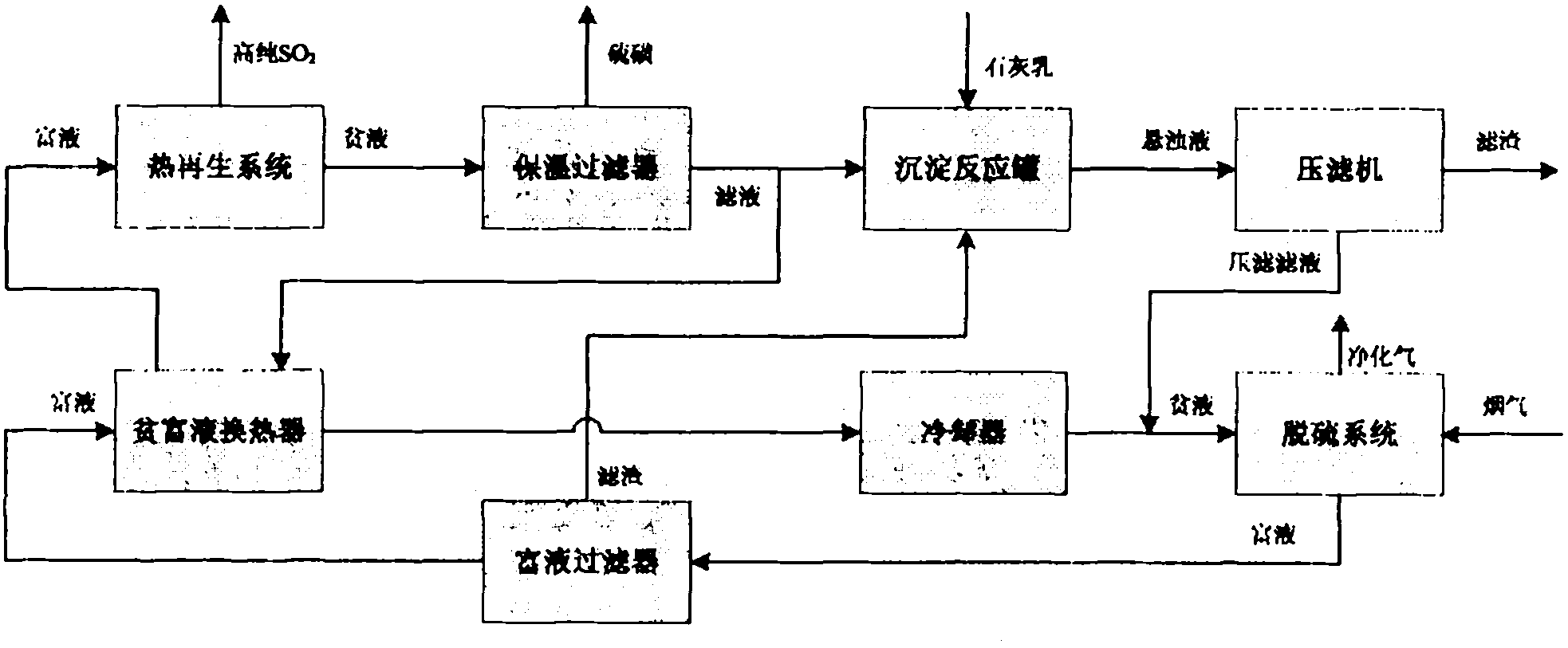

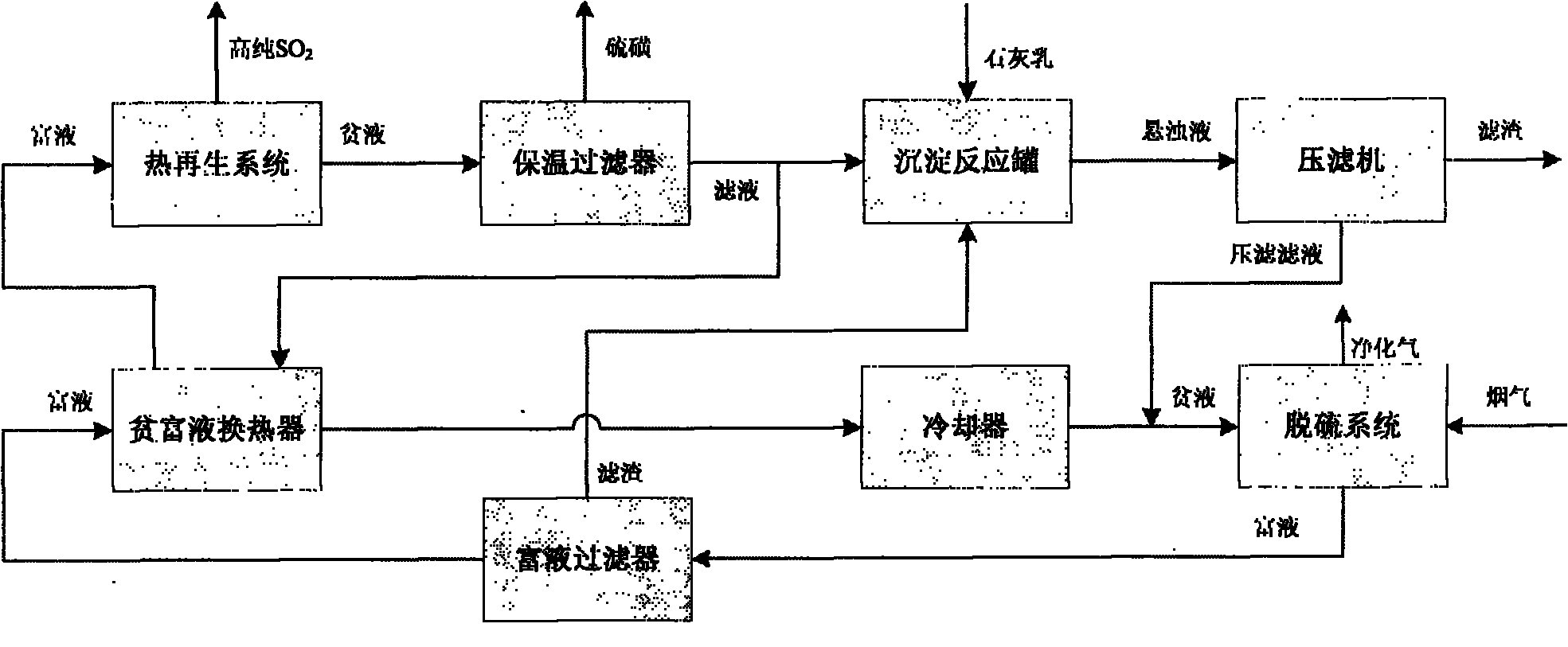

[0023] Taking the purification of desulfurization solvent in sintering flue gas desulfurization by solvent circulation absorption method in a steel plant as an example, combined with figure 1 The present invention will be described.

[0024] Desulfurization solvent lean liquid absorbs SO in flue gas in desulfurization system 2 A desulfurization solvent-rich liquid with a temperature of about 52°C is formed. The rich liquid passes through a bag-type rich liquid filter to filter out solid residues, then passes through a lean-rich liquid heat exchanger for heat exchange, and then enters a thermal regeneration system for heating and regeneration. During the heating process, the SO absorbed by the rich solution 2 with high purity SO 2 Desorbed in the form of desulfurization and sent to post-processing, the rich liquid can be regenerated into a desulfurization solvent lean liquid at about 100 °C. After the lean solution is filtered through a bag-type insulation filter to remove s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com