Twist drill with changeable helical angles

A technology of helix angle and twist drill, which is applied in the field of metal cutting tools, can solve the problems of difficulty in taking into account chip removal and cutting, the service life of the drill bit is reduced, and the cutting edge machinability is poor, so as to improve processing stability, reduce cutting heat, drill Sharpening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

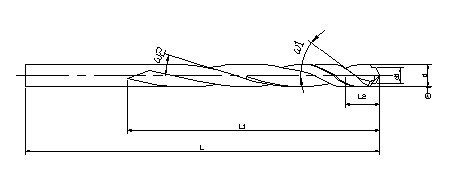

[0017] Use the same production batch of W6Mo5Cr4V2, Ф10.80 high-speed steel bars to produce Ф10 specification twist drills A and B (the heat treatment process of both is the same), A sample is the existing standard twist drill, B sample is the present invention Twist drill, the specific parameters are as follows:

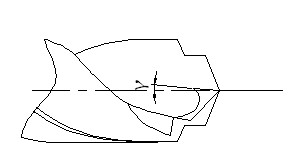

[0018] Sample A: total length L=133mm, working section length L1=87mm, working section helix angle 30°, diameter d=10mm, drill tip core thickness 1.6mm, chisel edge rake angle γ=-52°;

[0019] Sample B: total length L=133mm, working section length L1=87mm, working section front section length L2=15mm, front section helix angle ω1=37°, back section helix angle ω2=16°, diameter d=10mm, near the drill tip step The small diameter d1=6.8mm, the core thickness of the drill point is 0.15mm, and the chisel edge rake angle γ=5°.

[0020] Test method: TK7640 CNC vertical boring and milling machine, cutting speed: 28m / min, feed rate 0.25mm / r, drilling depth 30mm. Cutting tes...

Embodiment 2

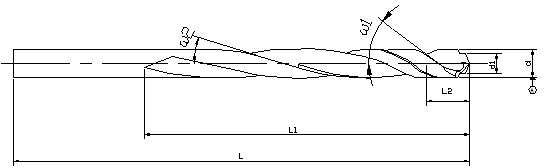

[0026] Use the same production batch of W9Mo3Cr4V, Ф6.6 high-speed steel bars to produce Ф6.0 specification straight shank twist drill samples A and B (same heat treatment process), sample A is the existing standard twist drill, sample B is based The twist drill invented, the specific parameters are as follows:

[0027] Sample A: total length L=101mm, working section length L1=63mm, working section helix angle 30°, diameter d=6mm, drill tip core thickness 1.05mm, chisel edge rake angle γ=-53°;

[0028] Sample B: total length L=101mm, length of working section L1=63mm, length of front section of working section L2=10mm, helix angle of front section ω1=36°, helix angle of back section ω2=16°, diameter d=6mm, near the drill tip step The small diameter d1=4.2mm, the core thickness of the drill point is 0.12mm, and the chisel edge rake angle γ=4°.

[0029] Test method: TK7640 CNC vertical boring and milling machine, cutting speed: 28m / min, feed rate 0.17mm / r, drilling depth 20mm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com