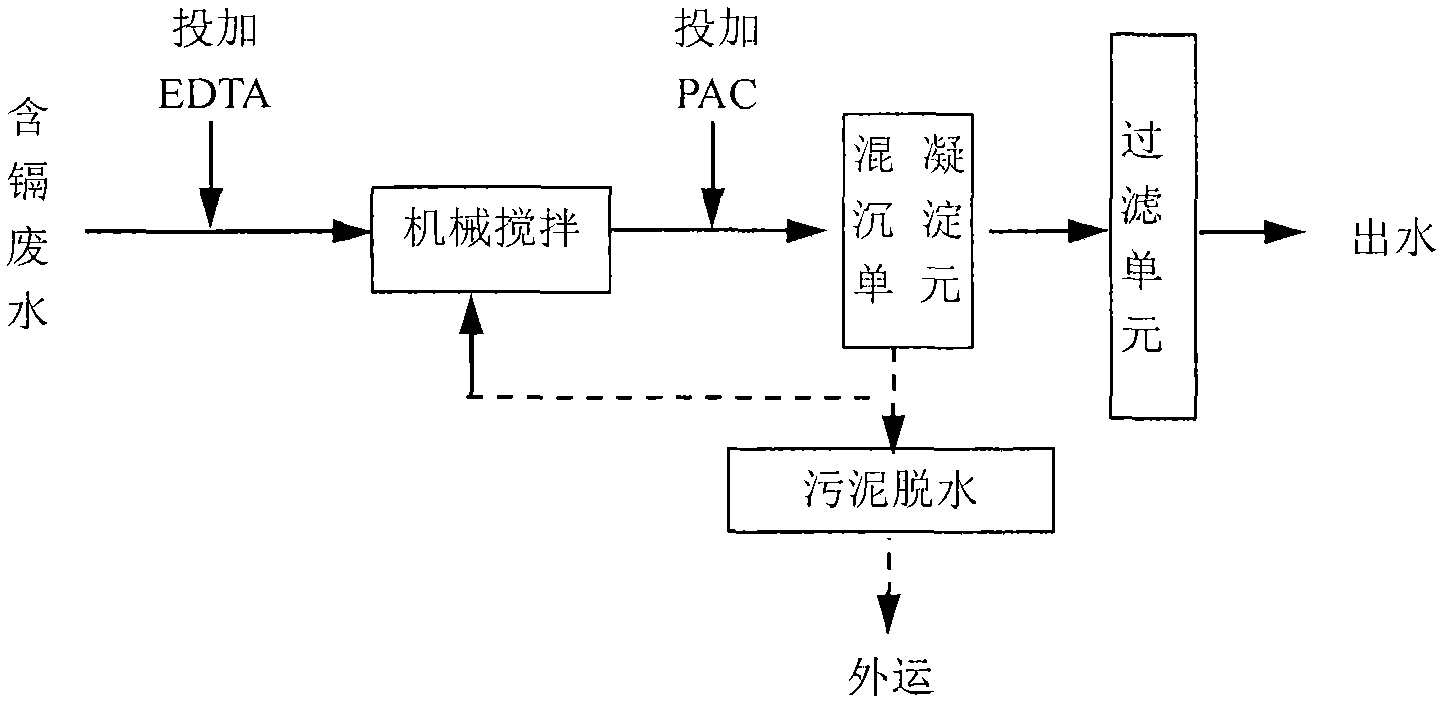

Method for treating trace amount of cadmium in wastewater by chelation, coagulation and ultrafiltration combination

A chelation and trace technology, applied in the direction of flocculation/sedimentation water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problem of difficult removal of trace cadmium, achieve low cost, simple operation process, Good effect in removing trace heavy metal ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The nanofiltration effluent in the metallurgical wastewater treatment process of a smelter in Yunnan is the research object. The concentration of cadmium ions in the carbon effluent water is 0.019-0.025mg / L, Cl - The concentration is about 2500mg / L, and the initial pH is 11.

[0023] Using the method of the present invention to remove cadmium: 1) Take a certain volume of nanofiltration water, add 10 mg / L of EDTA, stir for 25 minutes, and various forms of cadmium are chelated. 2) Then add 50 mg / L PAC for coagulation and sedimentation for 30 minutes to coagulate and settle the EDTA chelated with cadmium. 3) carry out through ultrafiltration membrane, ultrafiltration treatment. The amount of residual cadmium detected by the analysis is 0.0048mg / L, reaching the limit value of cadmium in Class II water bodies (≤0.005mg / L) in the "Environmental Quality Standards for Surface Water" (GB 3838-2002).

Embodiment 2

[0025] The carbon filter effluent in the metallurgical wastewater treatment process of a smelter is the research object. The concentration of cadmium ions in the carbon filter water is 0.045-0.054mg / L, Cl - The concentration is about 2500mg / L, and the initial pH is 10.84.

[0026] Using the method of the present invention to remove cadmium: 1) Add 10 mg / L of EDTA to the effluent of the carbon filter, and perform stirring and chelating treatment for 0.5 h. 2) Add 100mg / L PAC for 0.5h to coagulate and settle the EDTA chelated with cadmium. 3) The ultrafiltration unit performs ultrafiltration treatment. 4) The amount of residual cadmium measured by analysis is 0.0041mg / L, reaching the limit value of cadmium in Class II water bodies (≤0.005mg / L) in the "Environmental Quality Standards for Surface Water" (GB 3838-2002).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com