Method for smelting clean steel in electromagnetic induction furnace by blowing CO2

A technology of electromagnetic induction furnace and smelting method, which is applied in the direction of electric furnace, furnace, furnace type, etc., to achieve the effect of reducing the amount of alloy, reducing the phenomenon, and slowing down the greenhouse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: An electromagnetic induction furnace injects CO 2 The clean steel smelting method of decarburization is carried out on a 500kg multifunctional electromagnetic induction furnace. The ratio of raw materials is 248kg of scrap steel, 50kg of pig iron, 298kg of molten steel, and 20kg of slag, which are added before blowing. The initial conditions of raw materials are shown in Table 1 and Table 2.

[0042] Table 1 Metal Material Composition / %

[0043]

[0044] Table 2 Slag Composition / %

[0045]

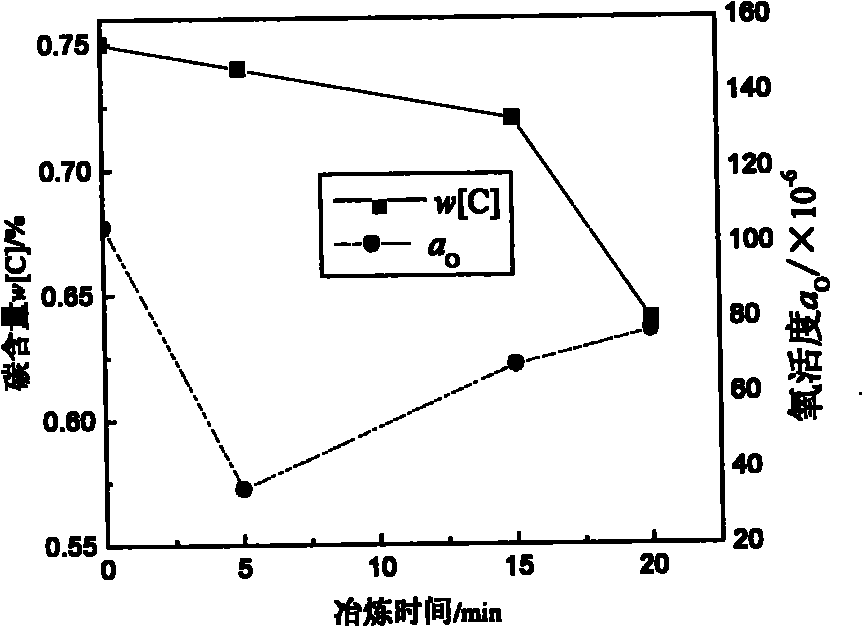

[0046] Melt the prepared charge to above 1600°C, using three kinds of CO 2 Experiment with the gas flow scheme, change the blowing gas flow every 5 minutes, and take temperature measurement and sampling, the bottom blowing Ar flow is 0.1-0.3Nm in the whole process 3 / (min·t), when the temperature is lower than 1500°C in the embodiment 2, measures to raise the temperature are taken, and the specific scheme is shown in Table 3.

[0047] Table 3 Smelting scheme...

Embodiment 2

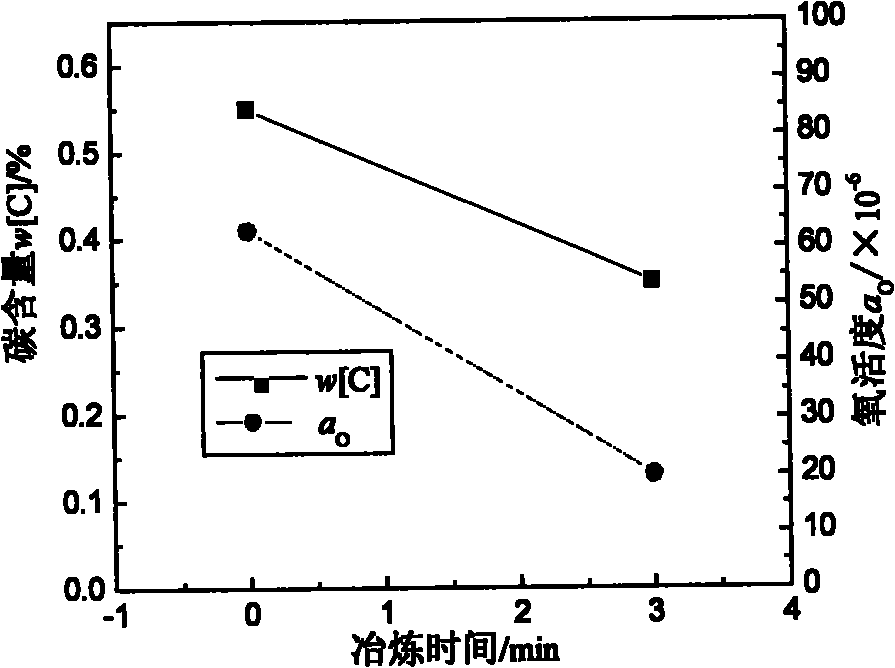

[0052] Embodiment 2: carry out on the 500kg multifunctional electromagnetic induction furnace. The ratio of raw materials is 220kg of scrap steel, 70kg of pig iron, 290kg of molten steel, and 20kg of slag, which are added before blowing. The initial conditions of the raw materials are the same as in Example 1.

[0053] Melt the prepared charge to above 1600°C, and the flow of Ar at the bottom of the whole process is 0.1-0.3Nm 3 / (min·t), when the temperature is lower than 1500°C, temperature rise measures are taken, and temperature measurement and sampling are carried out. When the measured carbon content is 0.35%, the blowing gun is stopped. The details and results are shown in Table 5. It can be seen that when the decarburization amount is 0.20%, the oxygen activity in molten steel does not increase.

[0054] Table 5 patent embodiment result

[0055]

Embodiment 3

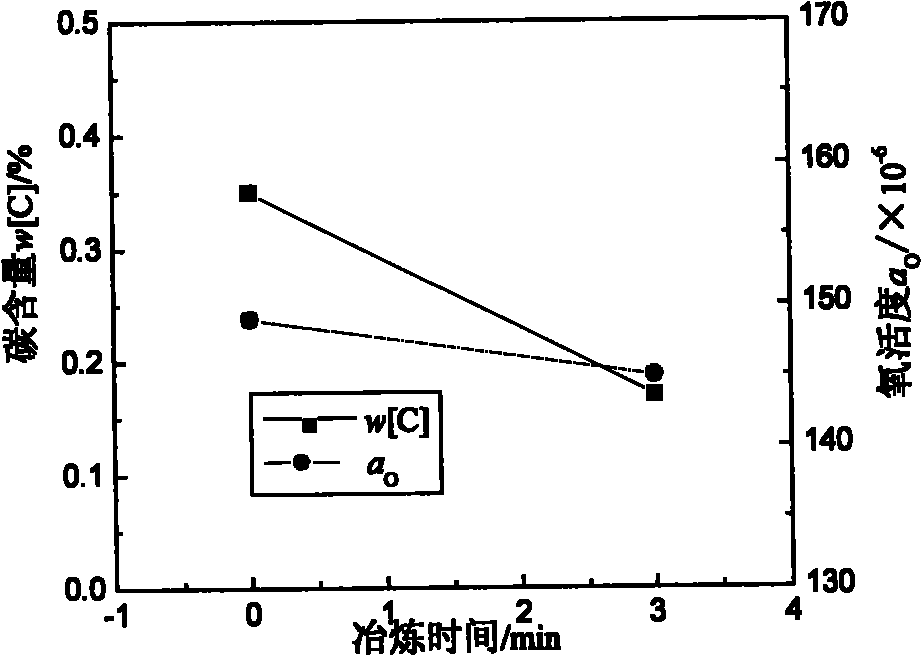

[0056] Embodiment 3: carry out on the 500kg multifunctional electromagnetic induction furnace. The ratio of raw materials is 236kg of scrap steel, 50kg of pig iron, 286kg of molten steel, and 20kg of slag, which are added before blowing. The initial conditions of the raw materials are the same as in Example 1.

[0057] Melt the prepared charge to above 1600°C, and the flow of Ar at the bottom of the whole process is 0.1-0.3Nm 3 / (min·t), when the temperature is lower than 1500°C, temperature rise measures are taken, and temperature measurement and sampling are carried out. When the measured carbon content is 0.17%, the blowing gun is stopped.

[0058] The details and results are shown in Table 6. Injecting CO 2 While decarburization is achieved, the oxygen activity in molten steel basically does not increase.

[0059] Table 6 patent embodiment result

[0060]

[0061] The above-mentioned embodiment adopts blowing O 2 When decarbonizing, under the same conditions, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com