Manufacturing method of ultraviolet LED (light-emitting diode)

A manufacturing method and ultraviolet technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low output power of ultraviolet LEDs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

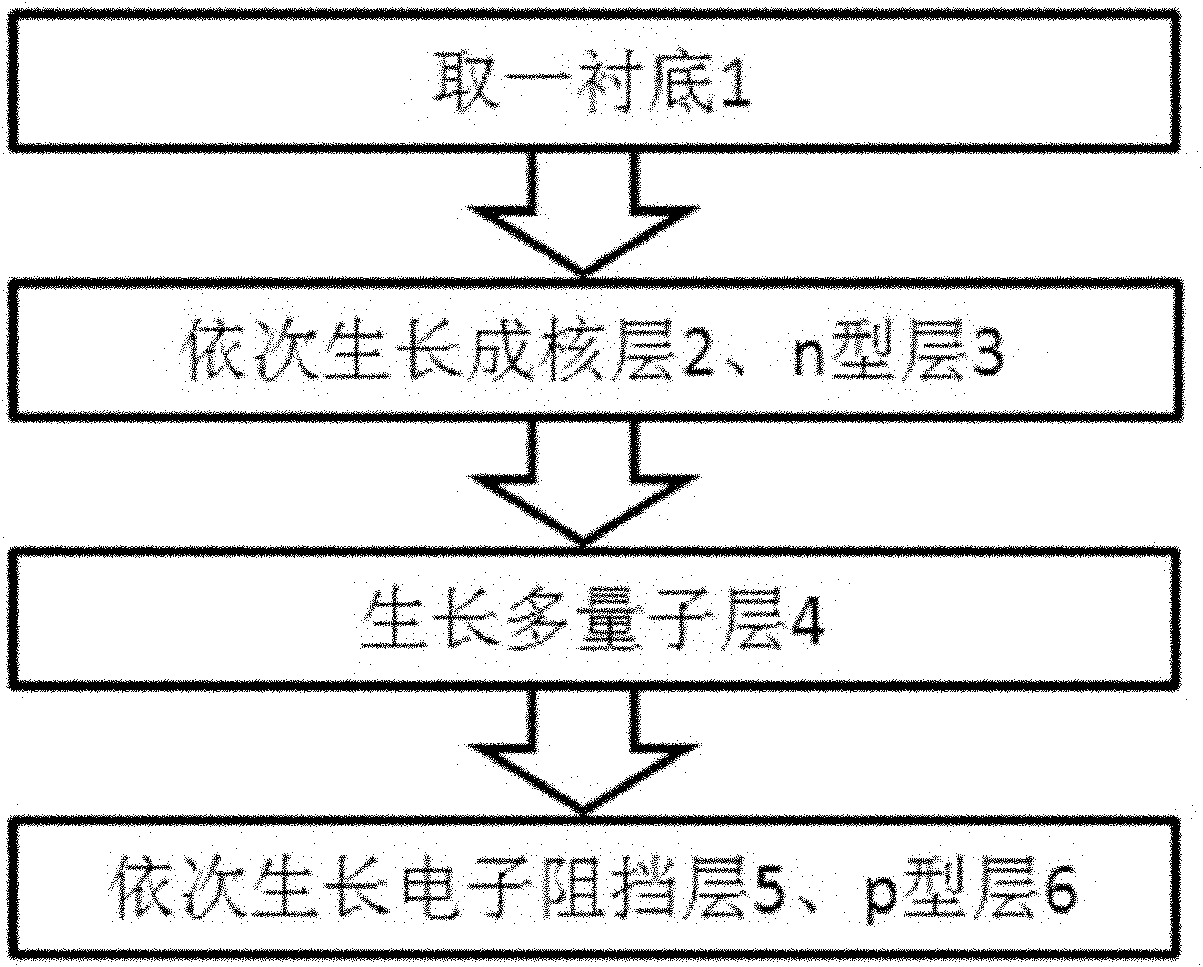

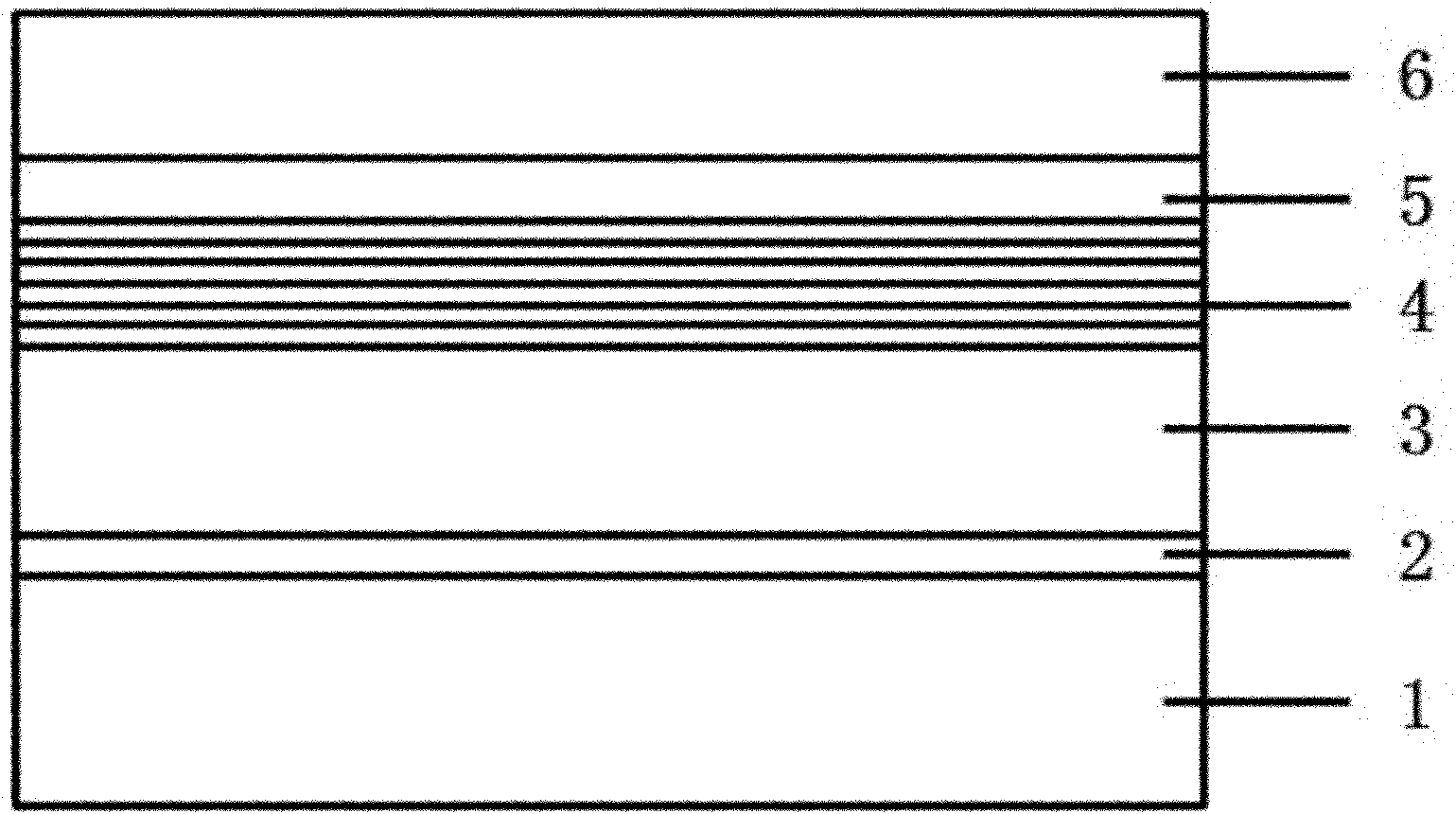

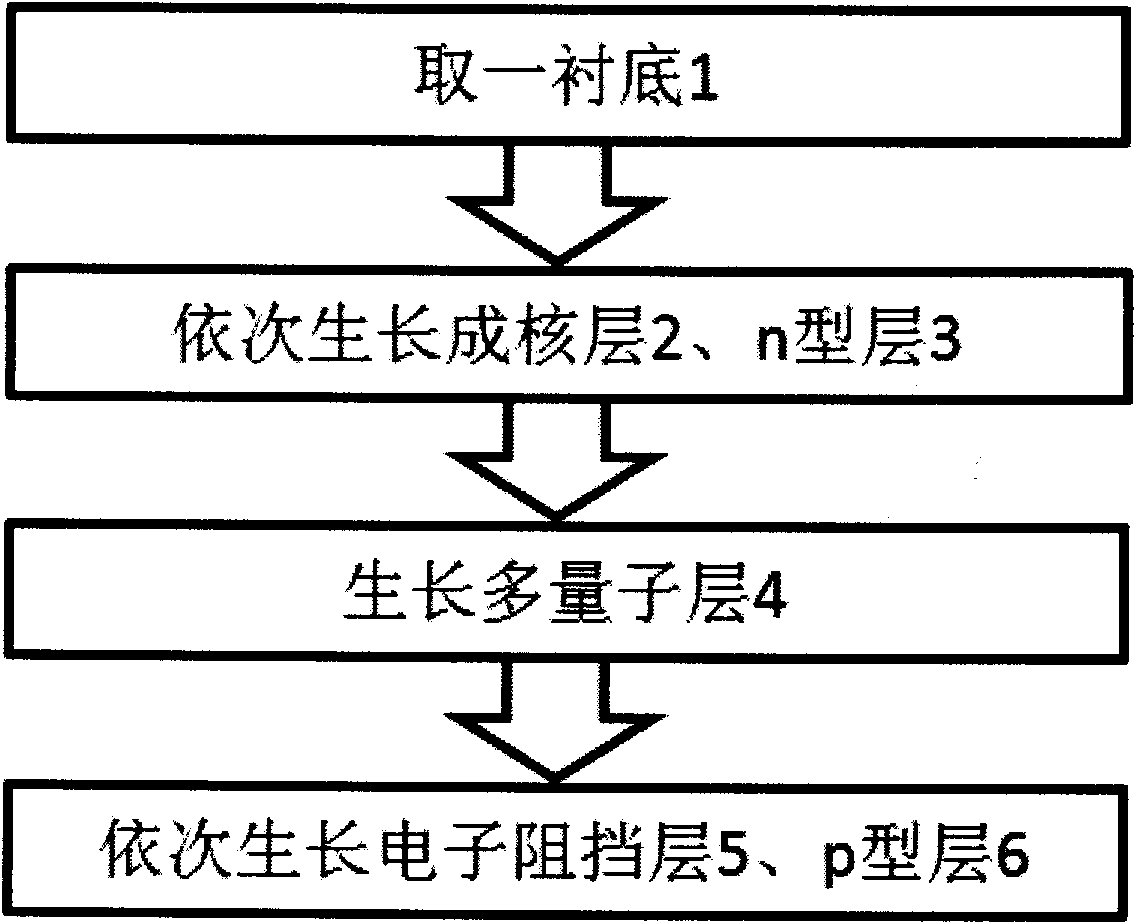

[0032] see again figure 1 and figure 2 , the invention provides a kind of manufacture method of ultraviolet LED, comprises the following steps:

[0033] Step 1: Take a sapphire substrate 1;

[0034] Step 2: growing a nucleation layer 2 and an n-type layer 3 sequentially on the substrate 1, the nucleation layer 2 is low-temperature GaN, its growth temperature is 550°C, and the thickness is 30nm; the n-type layer 3 is high-temperature GaN layer, the growth temperature is 1050°C, and the thickness is 1.5μm;

[0035] Step 3: growing a multi-quantum well layer 4 on the n-type layer 3, the multi-quantum well layer 4 is AlInN / GaN, the thickness of the well layer is 3.0nm, the thickness of the barrier layer is 12.0nm, and the number of periods is 5;

[0036] Step 4: growing an electron blocking layer 5 and a p-type layer 6 on the multi-quantum well layer 4 respectively, the electron blocking layer 5 is an AlInN layer, its doping type is p-type, the growth temperature is 800°C, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com