Polyolefin microporous diaphragm and preparation method thereof

A microporous diaphragm and polyolefin technology, which is applied to electrical components, circuits, battery pack components, etc., can solve the problems of polyolefin microporous membranes such as low strength, poor pore consistency, and low porosity, and achieve easy pore formation, High porosity and uniform pore formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

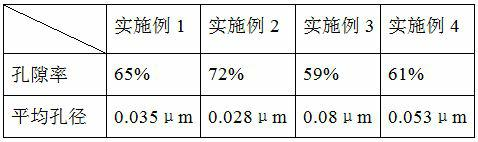

Examples

Embodiment 1

[0022] Example 1 In this example, a polyolefin microporous membrane, 0.001% by mass of benzoic acid and 0.001% of dibutylhydroxytoluene are added to the polyolefin resin; in the polyolefin resin, the mass percentage of ultra-high molecular weight polyolefin The percentage is 5%, and the balance is high-density polyolefin.

[0023] The specific preparation method is:

[0024] (1) Add ultra-high molecular weight polyethylene resin into the mixer, melt it at 200°C and stir it evenly;

[0025] (2) Cool the above molten liquid for 10 minutes, cool to 150°C, add high-density polyethylene resin, benzoic acid, dibutyl hydroxytoluene, melt at 150°C and stir evenly;

[0026] (3) Extrude the molten liquid from the extruder at 100°C, and then cool it through the cooling roll at 40°C to obtain the original flat film, and the cooling time is 1 minute;

[0027] (4) Stretch the original flat film simultaneously in both directions at a temperature of 40°C, with a stretching ratio of 1:5;

...

Embodiment 2

[0029] Example 2 In this example, a polyolefin microporous membrane, a mixture of clay, gypsum, and mica with a mass percentage of 0.06% is added to the polyolefin resin, wherein the mass ratio of clay, gypsum, and mica is 1:1:1; 0.01% dibutyl hydroxytoluene; in the polyolefin resin, the mass percentage of ultra-high molecular weight polyolefin is 20%, and the balance is high-density polyolefin.

[0030] The specific preparation method is:

[0031] (1) Add ultra-high molecular weight polypropylene resin into the mixer, melt it at 220°C and stir it evenly;

[0032] (2) Cool the above molten liquid for 20 minutes, cool to 155°C, add high-density polypropylene resin, a mixture of clay, gypsum, mica, dibutyl hydroxytoluene, melt at 170°C and stir evenly;

[0033] (3) Extrude the molten liquid from the extruder at 150°C, and then cool it through the cooling roll at 70°C to obtain the original flat film, and the cooling time is 3 minutes;

[0034] (4) Stretch the original flat fil...

Embodiment 3

[0036] Example 3 In this example, a polyolefin microporous membrane, a mixture of chalk and calcium stearate with a mass percentage of 2% is added to the polyolefin resin, wherein the mass ratio of chalk and calcium stearate is 1:1; 0.05% butyl hydroxyanisole; in the polyolefin resin, the mass percentage of ultra-high molecular weight polyolefin is 35%, and the balance is high-density polyolefin.

[0037] The specific preparation method is:

[0038] (1) Add ultra-high molecular weight polyethylene resin into the mixer, melt it at 250°C and stir it evenly;

[0039] (2) Cool the above molten liquid for 25 minutes to 160°C, add high-density polypropylene resin, a mixture of chalk and calcium stearate, butylated hydroxyanisole, melt at 200°C and stir evenly;

[0040] (3) Extrude the molten liquid from the extruder at 200°C, and then cool it through the cooling roll at 100°C to obtain the original flat film, and the cooling time is 5 minutes;

[0041] (4) Stretch the original fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com