Secondary battery anode piece and preparation method thereof

A secondary battery and positive electrode technology, which is applied in the field of secondary battery positive electrodes and its preparation, can solve the problems of low high-current discharge capacity of secondary batteries, improve service life and high-current discharge capacity, improve utilization rate, Reduce the effect of oxygen evolution reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

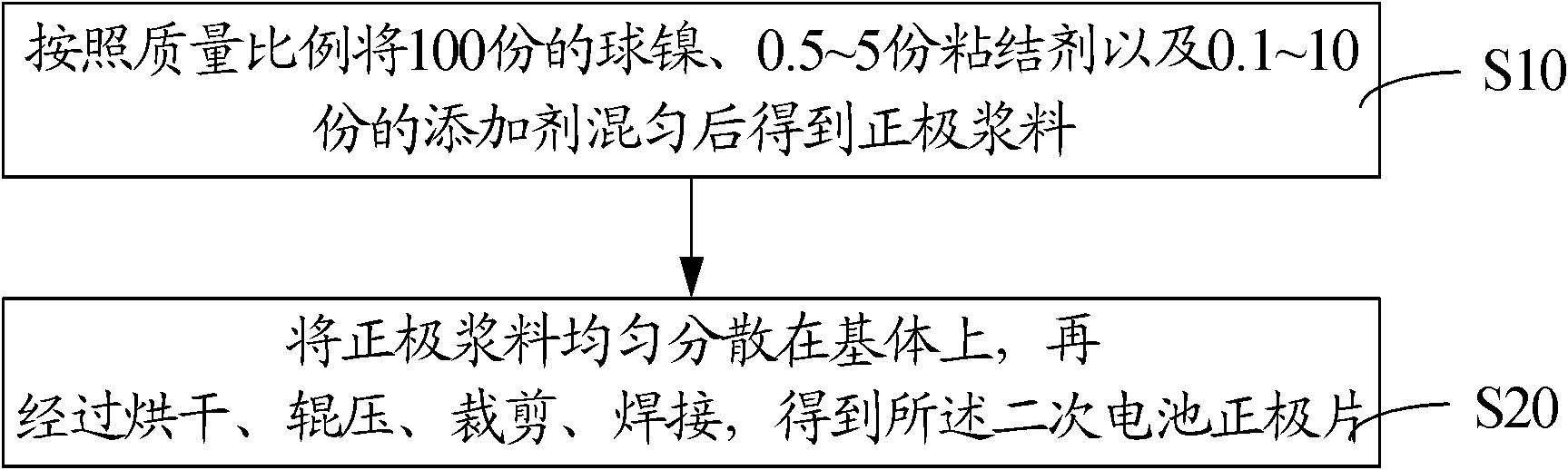

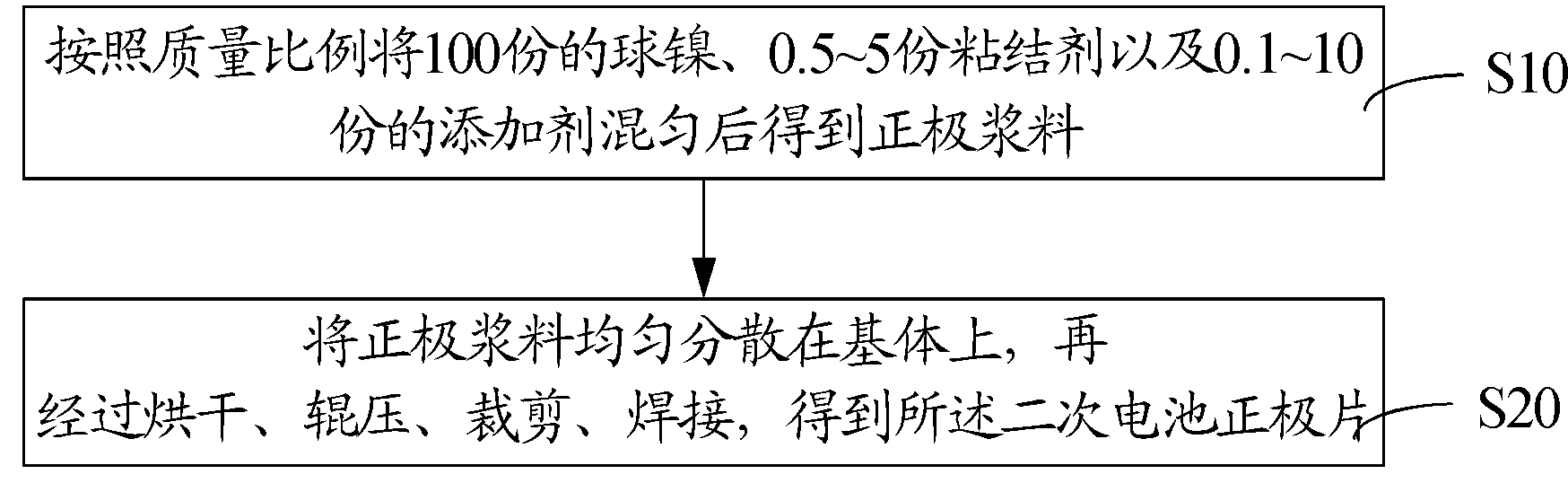

[0026] Such as figure 1 The preparation method of the above-mentioned secondary battery positive plate shown includes the following steps:

[0027] S10. Mix 100 parts of spherical nickel, 0.5-5 parts of binder and 0.1-10 parts of additives according to the mass ratio to obtain positive electrode slurry.

[0028] The positive electrode slurry may also include 0.1-10 parts of CoO.

[0029] The adhesive can be CMC, PTFE or HPMC.

[0030] S20, uniformly disperse the positive electrode slurry on the substrate, and obtain the positive electrode sheet of the secondary battery after drying, rolling, cutting and welding.

[0031] The base material can be bubble nickel, copper mesh or steel mesh.

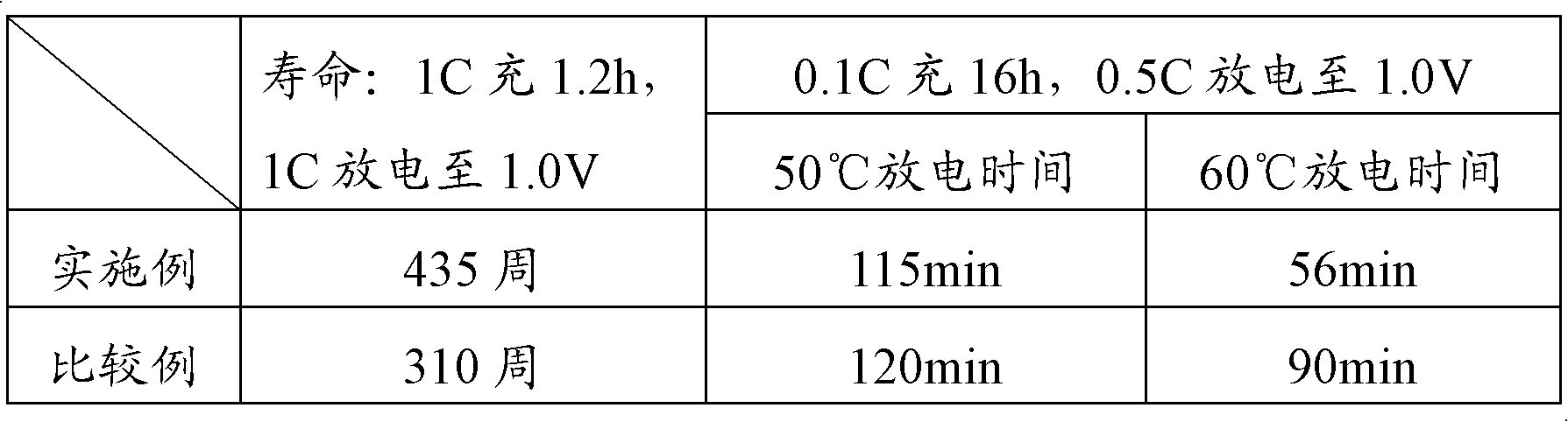

[0032] A secondary battery using the above-mentioned positive electrode sheet is provided below to illustrate the contribution of the above-mentioned positive electrode sheet to the high-current discharge capacity of the secondary battery.

Embodiment

[0034] Make the positive plate

[0035] Mix 100 parts of spherical nickel, 4 parts of CoO, 2 parts of CMC and 2 parts of additives according to the mass ratio, add an appropriate amount of water, mix and stir to obtain the positive electrode slurry, and evenly coat the positive electrode slurry on the substrate made of foamed nickel , and then go through drying, rolling, cutting, welding and other processes to make the positive electrode sheet.

[0036] For spherical nickel, choose Ni(OH) with a particle size of about 500nm 2 , the additives are LiOH and Li with a mass ratio of 1:1 2 CO 3 .

[0037] Making Negative Plates

[0038] According to the mass ratio, 100 parts AB 5 Mix hydrogen storage alloy powder, 0.5 parts of acetylene black and 0.5 parts of nickel powder, add an appropriate amount of adhesive SBR (styrene-butadiene rubber) and water, mix and stir to obtain negative electrode slurry, and evenly coat the negative electrode slurry on the nickel-plated surface. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com