Method of producing negative electrode for non-aqueous electrolyte secondary battery, negative electrode, and non-aqueous electrolyte secondary battery using the same

A non-aqueous electrolyte and secondary battery technology, which is applied in the direction of electrode manufacturing, secondary batteries, battery electrodes, etc., can solve the problem of cycle characteristics degradation, and achieve the suppression of the degradation of charge and discharge cycle characteristics, high reliability, and excellent charge and discharge Effects of Cyclic Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

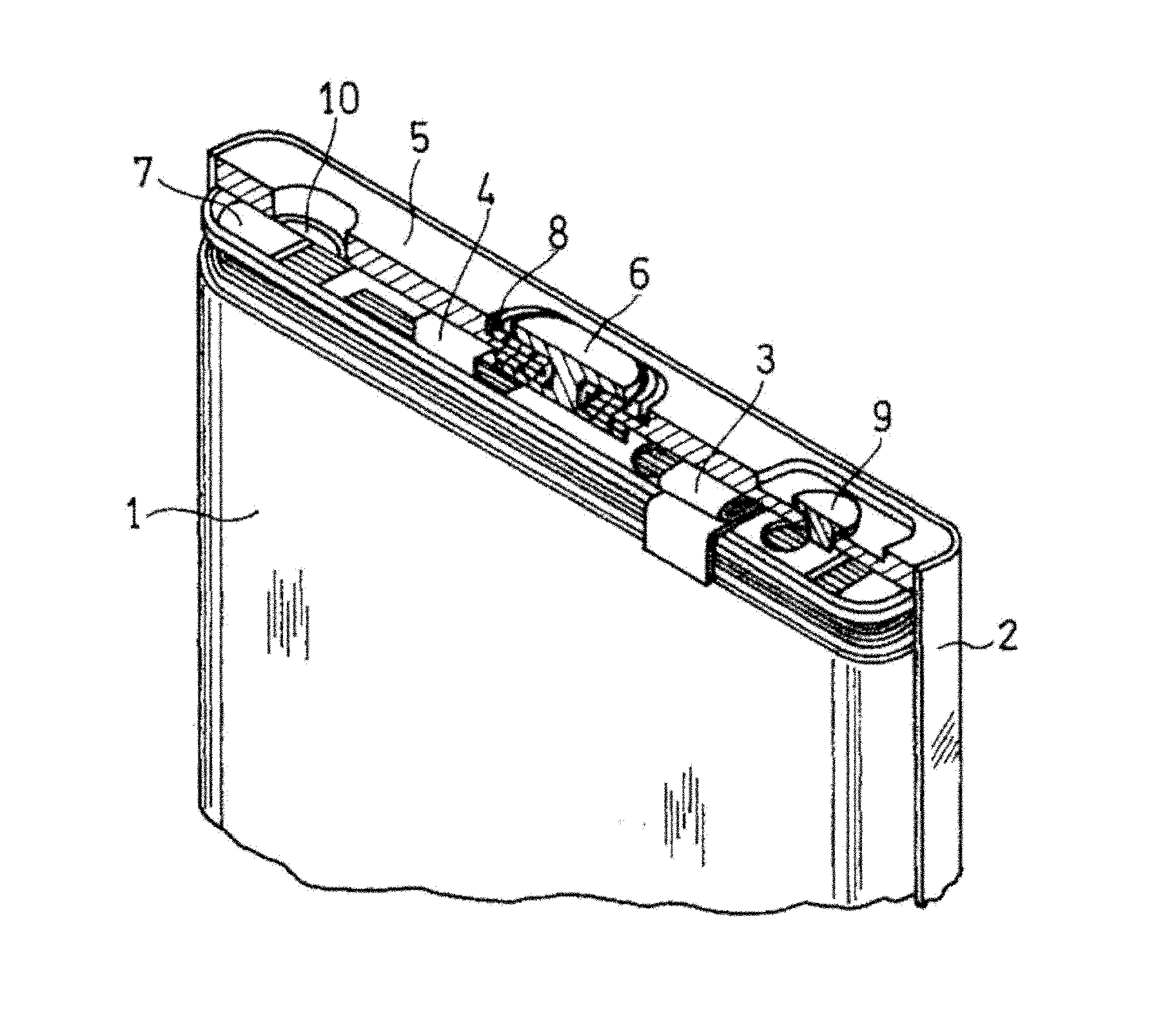

Image

Examples

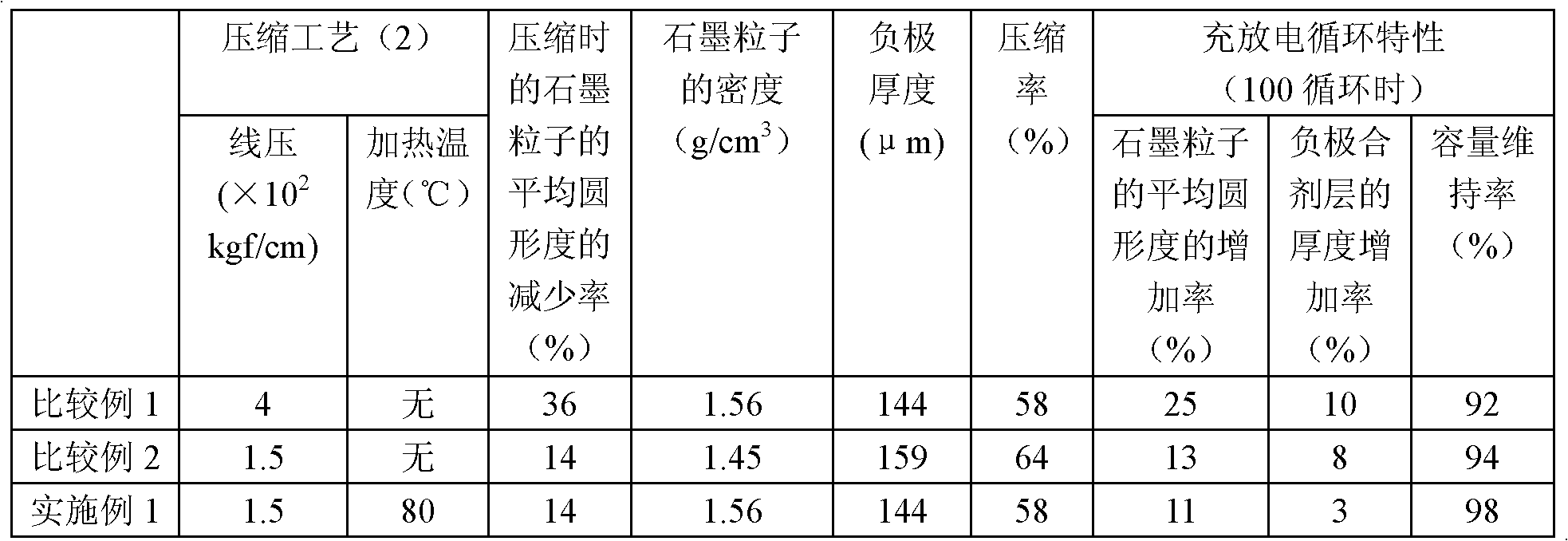

Embodiment 1

[0075] (1) Preparation of negative electrode

[0076] With artificial graphite 3kg (manufactured by Mitsubishi Chemical Co., Ltd., average particle diameter 20 μ m, average circularity 0.72) as the negative electrode active material, BM-400B (the styrene-butadiene rubber (SBR containing 40% by weight) made by Japan Zeon Co., Ltd. ) of aqueous dispersion) 75g, and 30g of carboxymethylcellulose (CMC) and an appropriate amount of water were stirred with a double-arm kneader to prepare negative electrode slurry. The negative electrode slurry was coated on both sides of the negative electrode core material formed by a copper foil with a thickness of 10 μm, and dried to form a negative electrode active material layer. In this way a negative electrode precursor is obtained.

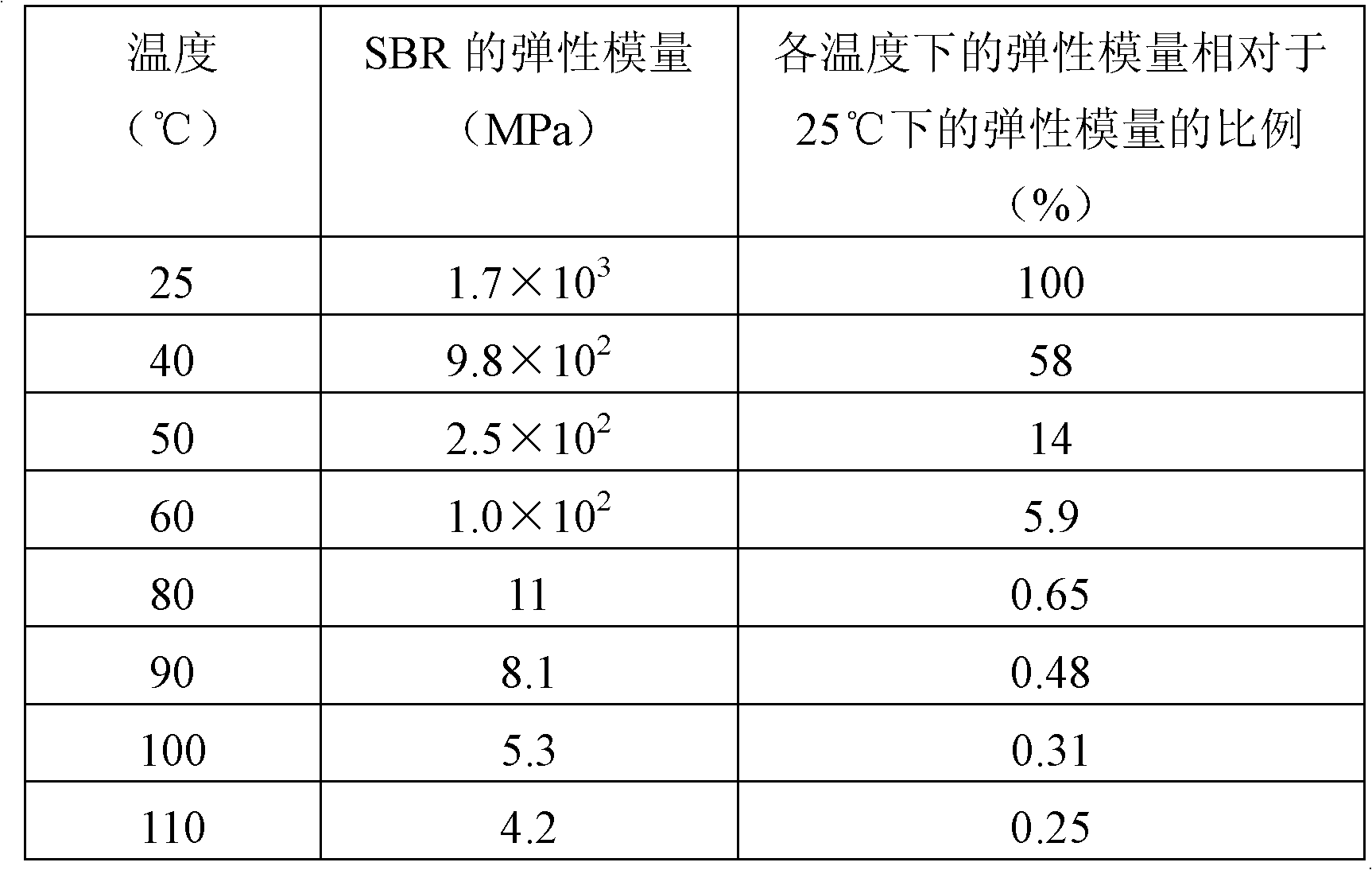

[0077] Then, the negative electrode precursor was compressed by passing between a pair of heated rollers. The number of times of compression is set to 1 time. More specifically, while heating the negative ele...

Embodiment 2

[0131] In addition to setting the line pressure in process (2) to 2.0×10 2 Except that kgf / cm and heating temperature were changed to the values shown in Table 3, a negative electrode was produced in the same manner as in Example 1. Using this negative electrode, a battery was fabricated by the same method as in Example 1. The negative electrodes and batteries were evaluated by the methods described above. The evaluation results are shown in Table 3.

[0132] table 3

[0133]

[0134] In negative electrodes B to E, the density of graphite particles in the negative electrode mixture layer is 1.5g / cm 3 As mentioned above, the decrease rate of the average circularity of graphite particles at the time of compression is 20% or less. In Batteries B to E in which the heating temperature in the step (2) was 50 to 100° C., a negative electrode having a high density of graphite particles in the negative electrode mixture layer was obtained, and excellent charge-discharge cycle ...

Embodiment 3

[0136] A negative electrode was produced in the same manner as in Example 1, except that the heating temperature in step (2) was set to 80° C. and the line pressure was changed to the value shown in Table 4. Using this negative electrode, a battery was fabricated by the same method as in Example 1. The negative electrodes and batteries were evaluated by the methods described above. The evaluation results are shown in Table 4.

[0137] Table 4

[0138]

[0139] In negative electrodes G~J, the density of graphite particles in the negative electrode mixture layer is 1.5g / cm 3 As mentioned above, the decrease rate of the average circularity of the graphite particles at the time of compression is 30% or less. The line pressure in process (2) is 1.0×10 2 ~3.0×10 2 In Batteries G to J of kgf / cm, negative electrodes having a high density of graphite particles in the negative electrode mixture layer were obtained, and excellent charge-discharge cycle characteristics were obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com