Power unit of mobile cutter frame

A technology for moving tool holders and power units, which is applied to the parts of boring machines/drilling machines, metal processing equipment, drilling/drilling equipment, etc., which can solve the problems of increasing the cost of pipeline manufacturing and processing, so as to ensure the quality of work and reliable power unit, reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

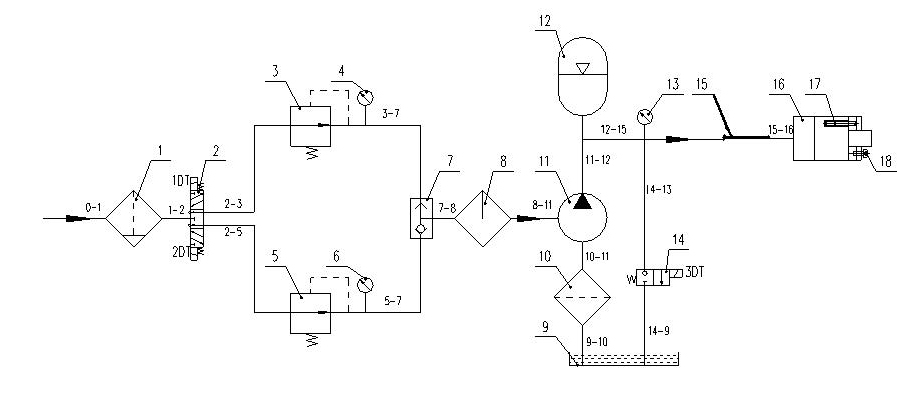

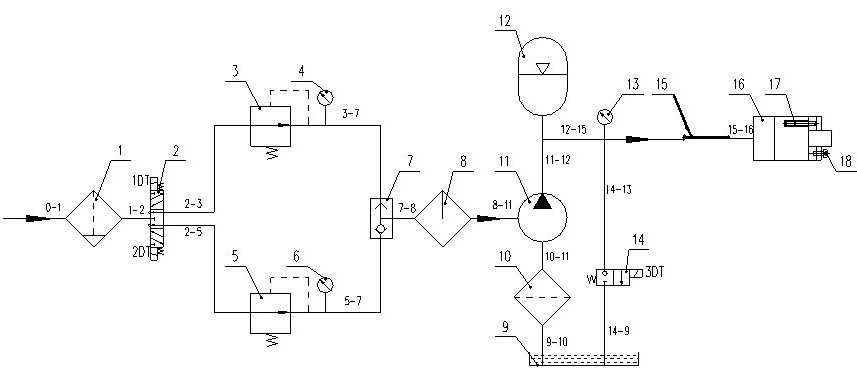

[0020] like figure 1 As shown, a movable tool post power unit includes a pneumatic power unit and a hydraulic power unit. The pneumatic power unit includes air source, air filter 1, pneumatic electromagnetic reversing valve 2, preload pressure reducing valve 3, preload pressure gauge 4, working pressure reducing valve 5, working pressure gauge 6, pneumatic shuttle valve 7 , Lubricator 8. The hydraulic power unit includes a fuel tank 9 , an oil filter 10 , an air-liquid pump 11 , an accumulator 12 , an oil pressure gauge 13 , an electromagnetic ball valve 14 , a high-pressure rubber hose 15 , and a moving tool rest cylinder 16 .

[0021] The air source is connected to the inlet of the air filter 1 through the pipeline 0-1, and the outlet of the air filter 1 is connected to the inlet of the pneumatic electromagnetic reversing valve 2 through the pipeline 1-2. Pneumatic electromagnetic reversing valve 2 has two electromagnets 1DT and 2DT, has three working positions of upper, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com