Operating method for welding fillet weld of tube seat on header

An operation method and fillet weld technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as poor welding performance, reduce line energy, prevent welding cracks, and improve performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

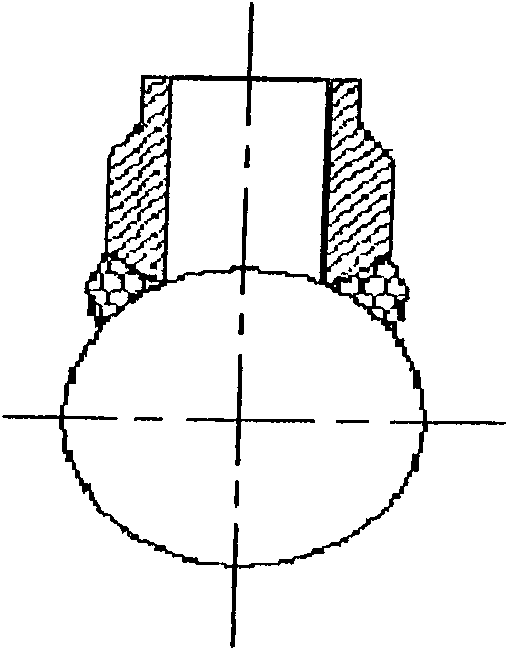

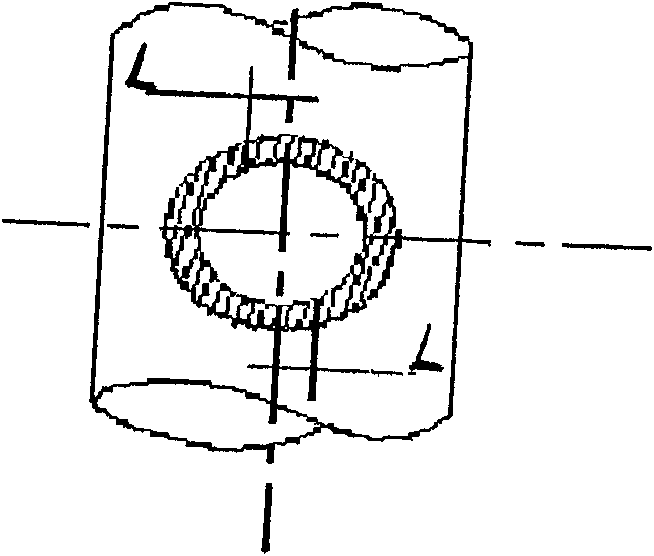

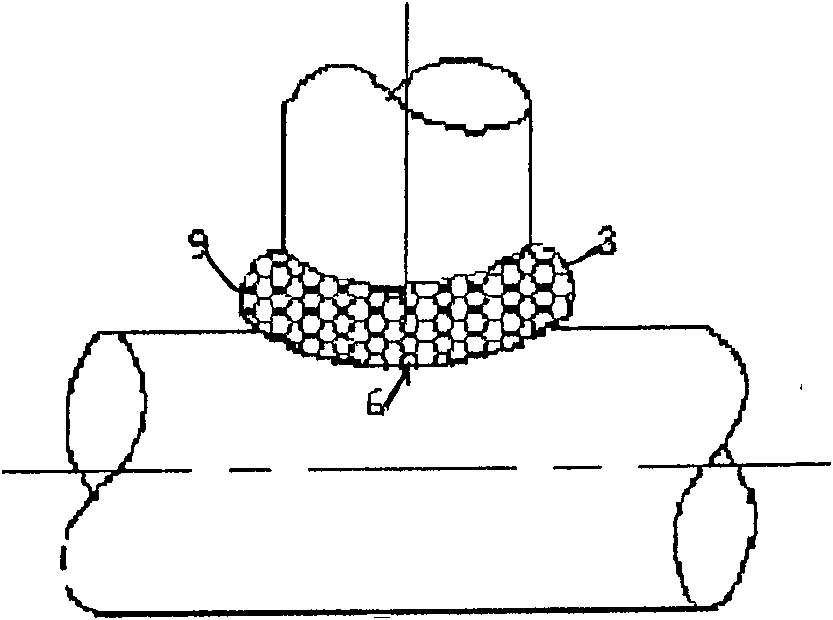

[0024] Specific embodiments: The present invention will be further described below in conjunction with the drawings;

[0025] The operation method of the fillet welding of header pipe seat is characterized in that the welding steps are as follows

[0026] 1. Bottom welding of fillet weld of header pipe seat

[0027] 1.1 The base fillet weld of the pipe seat is welded by manual argon arc welding. Due to the poor weldability of the material, both sides of the welding groove must be cleaned, and there should be no impurities such as rust, oil, and water; the blunt edge of the pipe seat is 1.0 mm, and there is a certain straight section, there is no gap between the pipe seat and the header body;

[0028] 1.2 SA-335 P91 material is prone to welding cracks, so during the bottom welding, the thickness of the deposited metal should not be too thin to prevent welding cracks due to the small boundary area of the deposited metal and cannot bear the stress. Generally, the thickness of the weld ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com