Vertically installed Spar-type floater for offshore wind generator and construction methods

A vertical column and column technology, which is applied to the vertical column floating wind power platform and its construction field, can solve the problems of difficult implementation, high installation cost, large wave force, etc., and achieves stable overall structural form, simple structure, and convenient construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

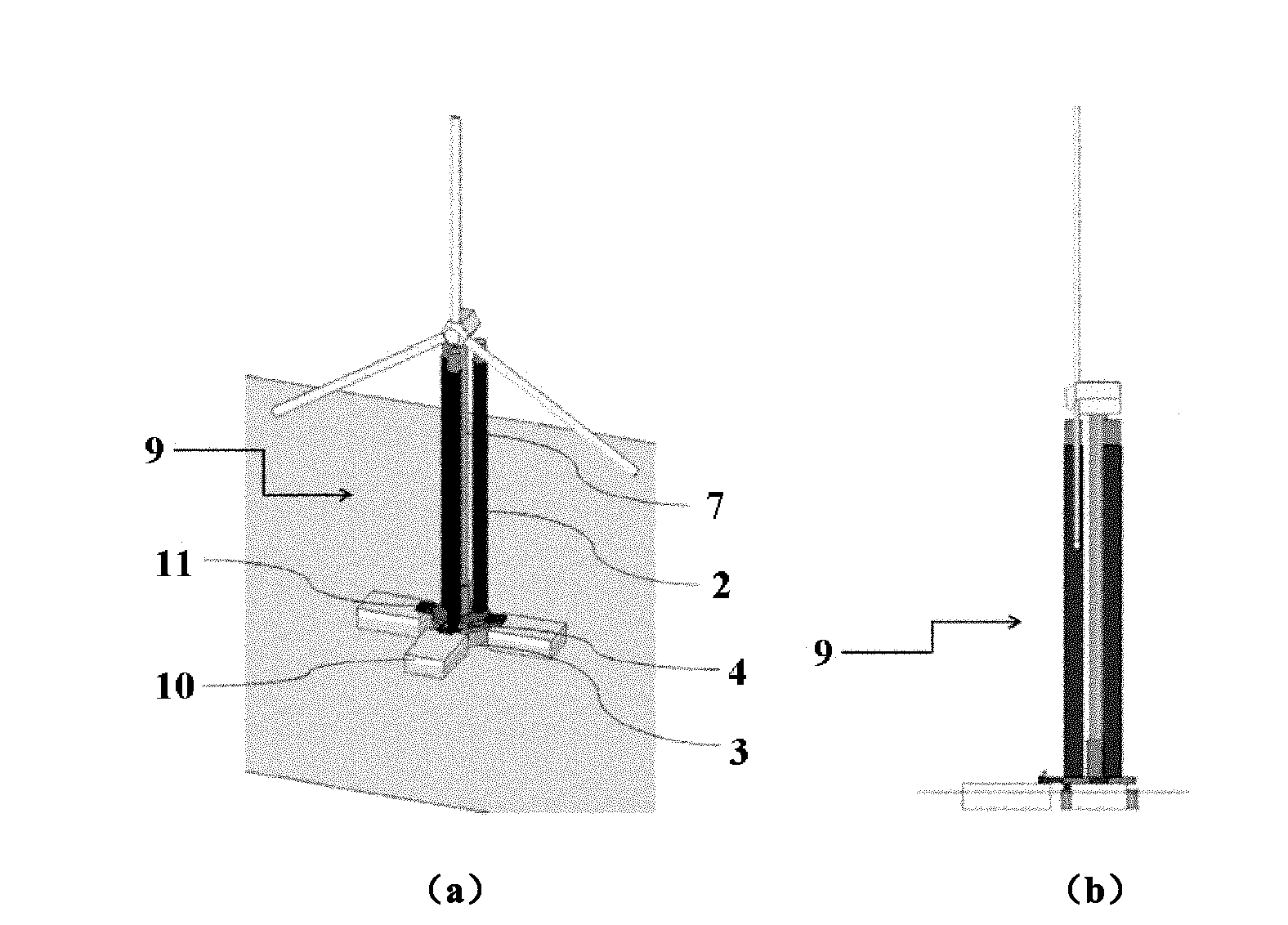

[0047] Such as Figure 5 As shown, the assembly method based on the above-mentioned vertical column type floating wind power platform 1 includes the following steps

[0048] e) tow the above-mentioned vertical towed platform 9 to the offshore wind farm;

[0049] f) Remove the towing reinforcement connected between the perforated deck 4 and the ballast tank 3, so that the ballast tank 3 is only connected to the bottom end of the deep draft column 2 and the deep draft column 2 is slidingly connected to the perforated deck, pressing The load compartment 3 drives the deep-draft column 2 to sink automatically under the action of gravity, and then injects seawater into the deep-draft column 2 to make the bottom of the deep-draft column 2 continue to sink until it reaches the preset draft position, and then the bottom of the deep-draft column 2 The top is fixedly connected with the porous deck 4;

[0050] g) start the locking and releasing mechanism 11 and tow the stabilizing barge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com