Quick starting method for aerobic granular sludge reactor for treating difficultly degraded waste water

An aerobic granular sludge and rapid start-up technology, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problems of slow start-up and low treatment efficiency of aerobic granular sludge reactors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

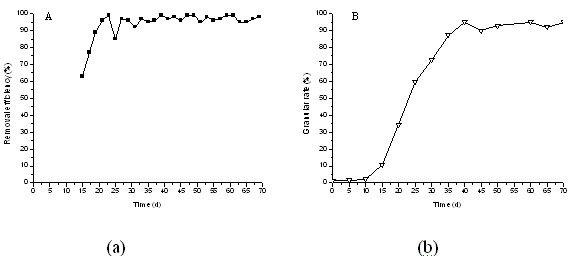

Embodiment 1

[0021] 1) The aeration sand head is evenly arranged at the bottom of the 5L sequencing batch bioreactor, and the external glass rotor gas flowmeter is used to control the surface gas velocity, and the external time control switch controls the automatic operation of the reactor;

[0022] 2) Use an organic load of 1.0kg m -3 d -1 In the simulated organic wastewater, sucrose was used as the single carbon source, and the activated sludge from Hangzhou Qige Wastewater Treatment Plant was activated and pretreated for 24 hours, and the activated and pretreated sludge was inoculated into the sequencing batch bioreactor , the biomass in the sequencing batch bioreactor is controlled at 3g·L -1 ;

[0023] 3) Start the sequencing batch bioreactor and control the surface gas velocity to 1.2cm s -1 , the influent uses sucrose as the carbon source, and the organic load is 1kg m -3 d -1 , the sludge settling time is 5min;

[0024] 4) The sequencing batch bioreactor runs for 7 days, and ...

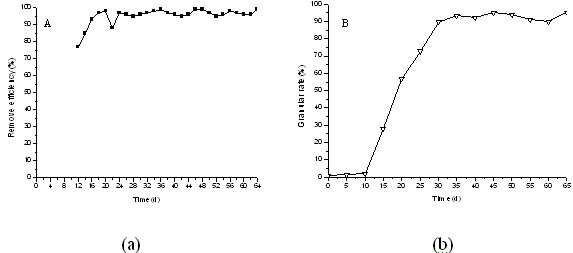

Embodiment 2

[0030] 1) The aeration sand head is evenly arranged at the bottom of the 5L sequencing batch bioreactor, and the external glass rotor gas flowmeter is used to control the surface gas velocity, and the external time control switch controls the automatic operation of the reactor;

[0031] 2) Use an organic load of 1.0kg m -3 d -1 In the simulated organic wastewater, sucrose was used as the single carbon source, and the activated sludge from Hangzhou Qige Wastewater Treatment Plant was activated and pretreated for 24 hours, and the activated and pretreated sludge was inoculated into the sequencing batch bioreactor , the biomass in the sequencing batch bioreactor was controlled at 5g·L -1 ;

[0032] 3) Start the sequencing batch bioreactor and control the surface gas velocity to 1.5cm s -1 , the influent uses sucrose as the carbon source, and the organic load is 1.6kg m -3 d -1 , the sludge settling time is 15min;

[0033] 4) The sequencing batch bioreactor runs for 10 days,...

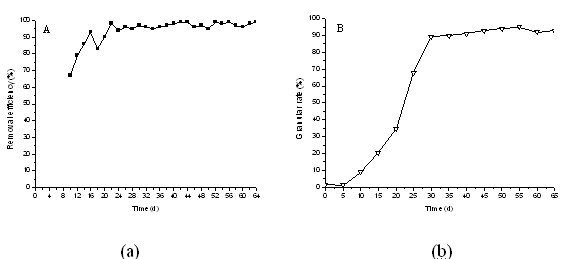

Embodiment 3

[0039] 1) The aeration sand head is evenly arranged at the bottom of the 5L sequencing batch bioreactor, and the external glass rotor gas flowmeter is used to control the surface gas velocity, and the external time control switch controls the automatic operation of the reactor;

[0040] 2) Use an organic load of 1.0kg m -3 d -1In the simulated organic wastewater, sucrose was used as the single carbon source in the simulated organic wastewater, and the activated sludge from Hangzhou Qige Wastewater Treatment Plant was activated and pretreated for 24 hours, and the activated and pretreated sludge was inoculated into the sequencing batch bioreactor , the biomass in the sequencing batch bioreactor was controlled at 4g·L -1 ;

[0041] 3) Start the sequencing batch bioreactor and control the surface gas velocity to 1.3cm s -1 , the influent uses sucrose as the carbon source, and the organic load is 1.4kg m -3 d -1 , the sludge settling time is 10min;

[0042] 4) The sequencing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com