Novel up-flow anaerobic sludge blanket for treating wastewater of pig farm

An up-flow anaerobic and pig farm wastewater technology, applied in the field of UASB) reactor, can solve the problem of not being able to process ammonia nitrogen at the same time, and achieve the effect of strong processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

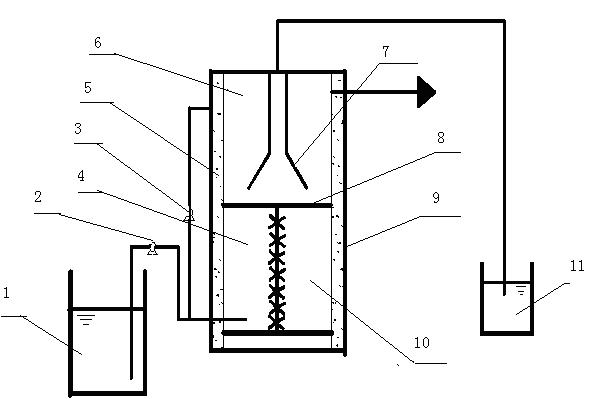

Image

Examples

Embodiment Construction

[0016] A large-scale pig farm adopts IC + SBBR + UASB combined process to treat pig wastewater. The effluent from the SBBR pool flows into the UASB reactor. After being treated by UASB, pollutants such as COD, ammonia nitrogen and nitrite nitrogen in the wastewater are further removed. After the wastewater is treated, the effluent quality meets the requirements of GB 18596-2001 "Discharge Standard of Pollutants for Livestock and Poultry Breeding Industry". UASB effluent COD 100 mg / L, NH 3 -N 40~80mg / L.

[0017] The specific implementation process is as follows:

[0018] (1) After the pig farm wastewater is collected by the sewage collection pipe network, it is intercepted by the mechanical grille to remove large particles of pollutants and floating objects in the sewage, and the wastewater enters the IC reactor.

[0019] (2) The waste water enters the IC reactor, undergoes high-efficiency anaerobic digestion, and after removing most of the COD to obtain biogas, the water qual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com