Ceramic filter element and production process thereof

A production process, a technology for ceramic filter elements, applied in the field of ceramic production technology, can solve the problems of high and severe microbial contamination, differences in secondary purification of tap water, oil and pesticide residues, etc., and achieve the effect of high filtration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

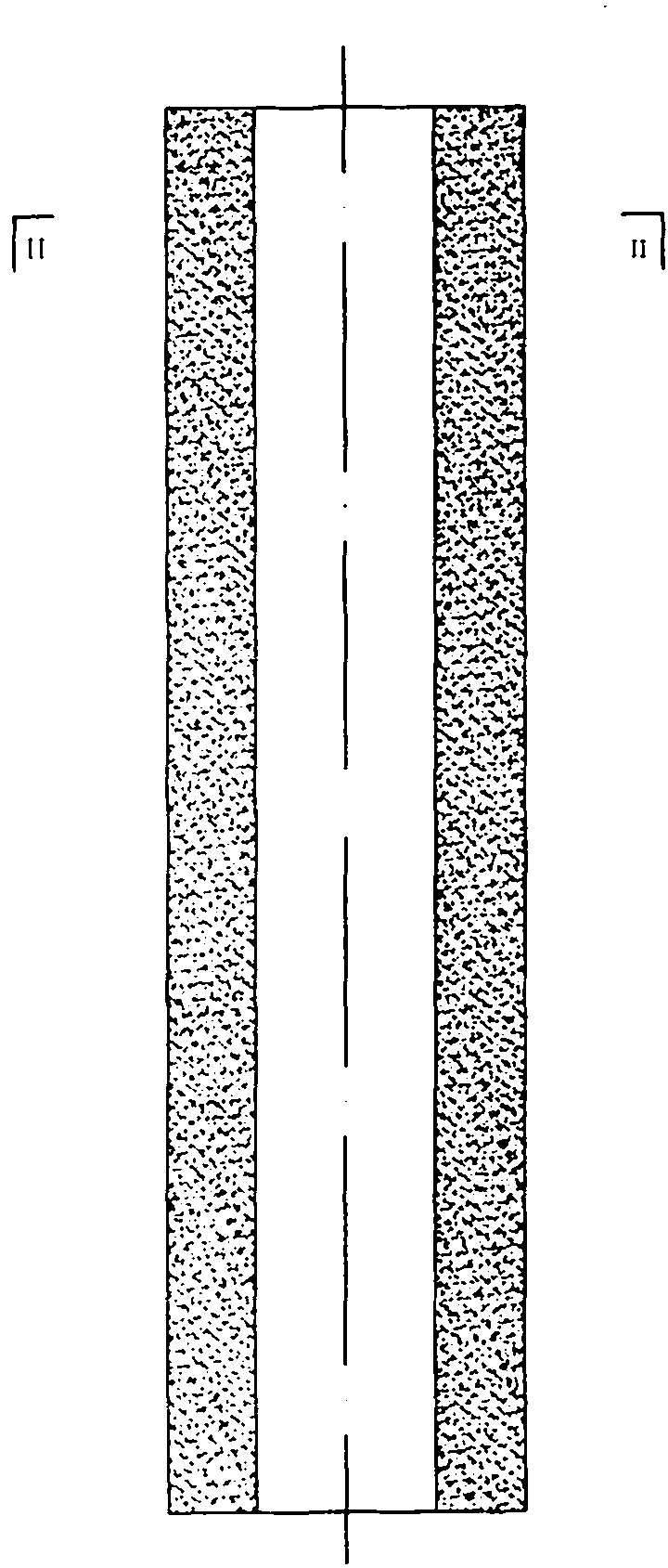

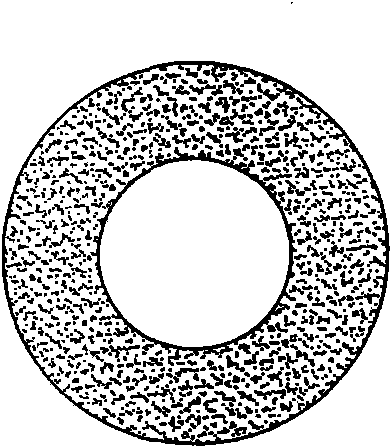

Image

Examples

Embodiment Construction

[0016] In order to better understand the present invention, the invention will be described in detail below in conjunction with specific examples.

[0017] As mentioned above, in order to overcome the problem that the existing ceramic filter element has an unsatisfactory purification effect on the water quality of the water cellar, the present invention provides a ceramic filter element developed for areas where rainwater is the only water source in northwest villages and towns and the production process of the ceramic filter element.

[0018] In response to the above situation, a certain proportion of attapulgite and bauxite were added on the basis of the original traditional diatomite firing, which enhanced the filter element's ability to adsorb organic phosphorus and carbamate pesticide residues in the water body and structural stress. At the same time, the sintering temperature of the firing process was optimized and controlled, and the research goal was achieved.

[0019...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com