Compounds containing phosphorus, nitrogen and transition metal elements, and preparation method thereof

A technology of transition metal elements and compounds, which is applied in the field of compounds containing phosphorus, nitrogen and transition metal elements and their preparation, can solve the problems of reduced catalytic flame retardant efficiency, failure to achieve flame retardant effect, poor uniform dispersion, etc., to reduce Peak heat release, prevent thermal degradation, and high flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Add 400ml of absolute ethanol solution containing 0.2mol salicylaldehyde into a 1L flask with condensing reflux and mechanical stirring, raise the temperature to 70°C within half an hour, then dissolve 0.1mol o-phenylenediamine in 200ml of absolute ethanol Slowly add it dropwise into the flask, finish the drop within 1 hour, continue to react for 0.5 hour, finally evaporate about 300ml of ethanol under reduced pressure, let the remaining mixture stand overnight, filter and wash with ethanol for 3 times, and then dry to obtain o-phenyl Diamine salicylaldehyde Schiff base 30.52g (about 0.096mol).

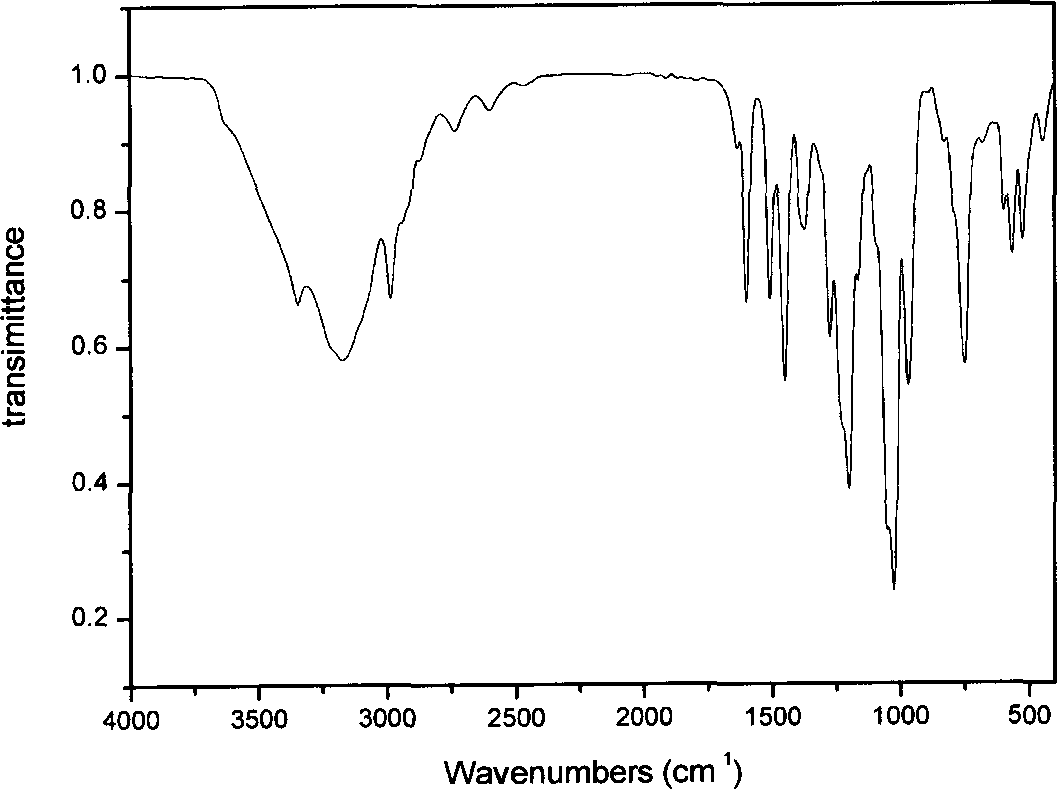

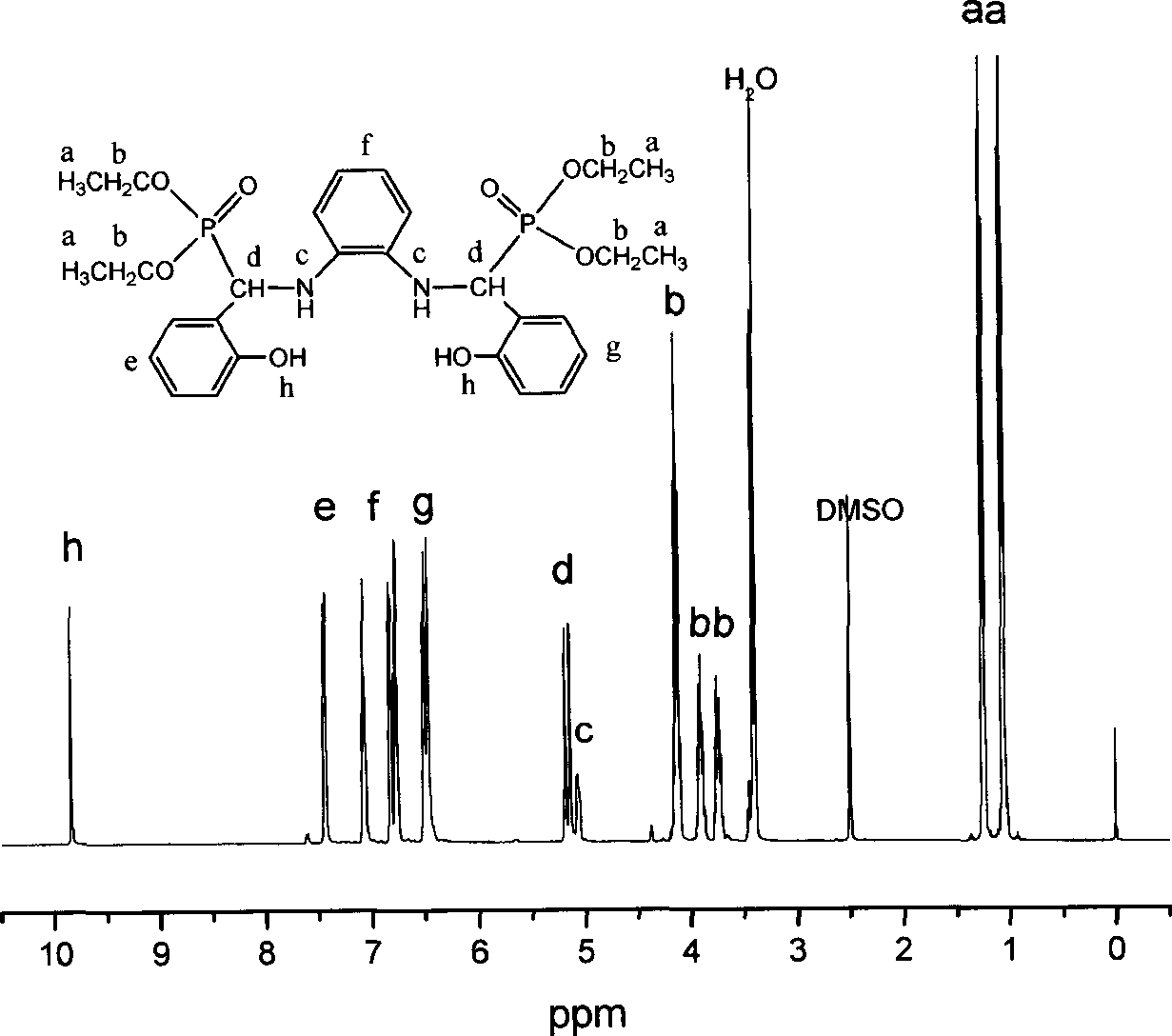

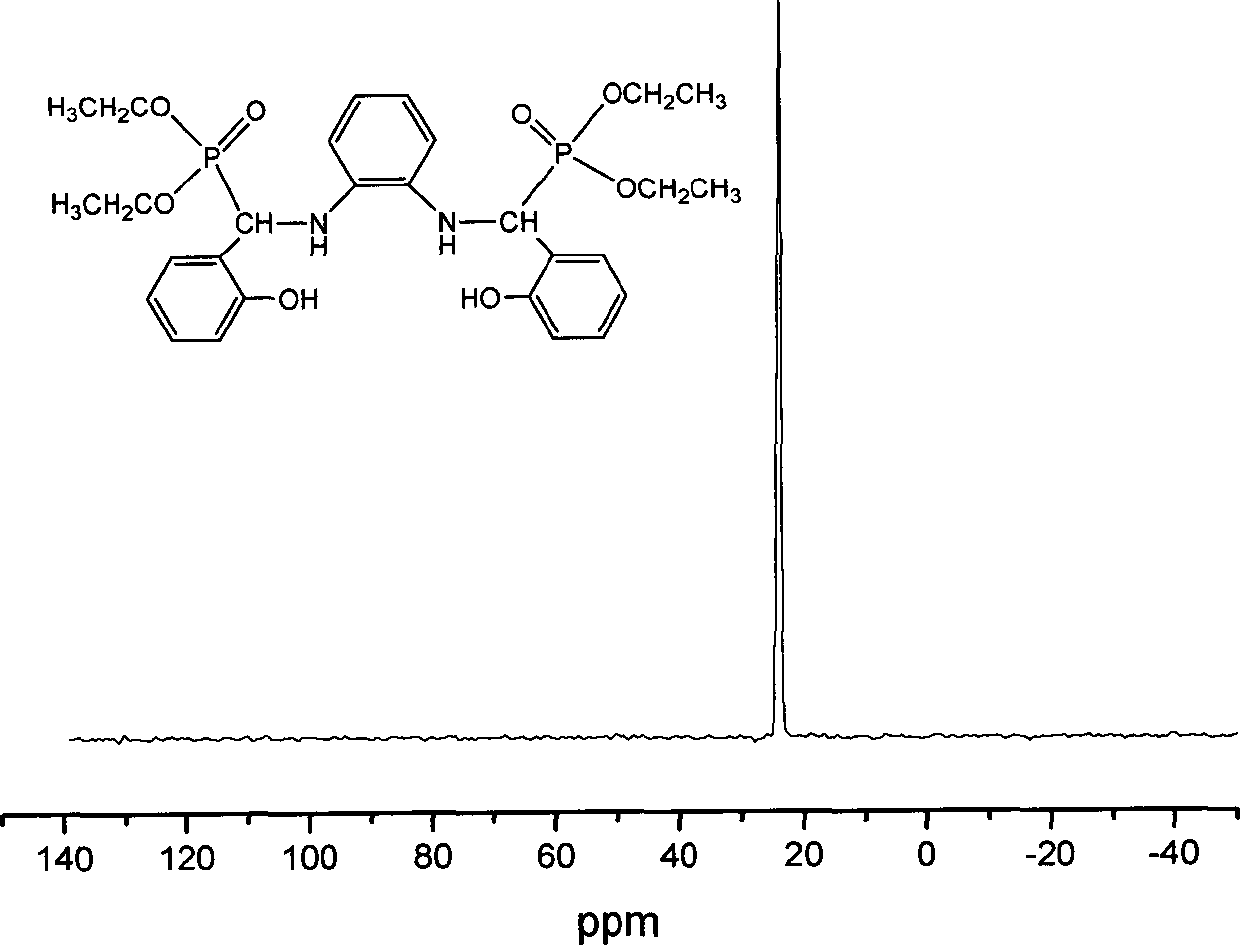

[0071] 0.1mol diethyl phosphite and 0.02mol o-phenylenediamine salicylaldehyde Schiff base are dispersed in 300ml absolute ethanol, and the mixture is placed in a 500ml three-neck flask with condensing reflux and mechanical stirring device for nitrogen gas flow, Heat to 65°C within half an hour. After reacting for 0.5 hours, add a small amount of sodium ethylate dropwise as a c...

Embodiment 2

[0085] Add 400ml of absolute ethanol solution containing 0.2mol salicylaldehyde into a 1L flask with condensing reflux and mechanical stirring, raise the temperature to 75°C within half an hour, then dissolve 0.1mol o-phenylenediamine in 200ml of absolute ethanol Slowly add it dropwise into the flask, finish dropping within 2 hours, continue to react for 0.5 hour, finally distill off about 300ml of ethanol under reduced pressure, leave the rest of the mixture overnight, filter and wash with ethanol for 3 times, then dry to obtain o-phenyl 31.43 g (about 0.097 mol) of diamine salicylaldehyde Schiff base.

[0086] 0.1mol diethyl phosphite and 0.04mol o-phenylenediamine salicylaldehyde Schiff base are dispersed in 300ml absolute ethanol, and the mixture is placed in a 500ml three-neck flask with condensing reflux and mechanical stirring device for nitrogen gas flow, Heat to 80°C within half an hour. After 1 hour of reaction, add a small amount of sodium ethoxide dropwise as a cat...

Embodiment 3

[0091] Add 400ml of absolute ethanol solution containing 0.2mol salicylaldehyde into a 1L flask with condensing reflux and mechanical stirring, raise the temperature to 80°C within half an hour, then dissolve 0.1mol of o-phenylenediamine in 200ml of absolute ethanol Slowly add it dropwise into the flask, finish dropping within 2 hours, continue to react for 4 hours, finally distill off about 300ml of ethanol under reduced pressure, leave the remaining mixture standing overnight, filter and wash with ethanol for 3 times, and then dry to obtain o-phenyl Diamine salicylaldehyde Schiff base 29.24g (about 0.94mol).

[0092] 0.1mol diethyl phosphite and 0.05mol o-phenylenediamine salicylaldehyde Schiff base are dispersed in 300ml absolute ethanol, and the mixture is placed in a 500ml three-neck flask with condensing reflux and mechanical stirring device for nitrogen gas flow, Heat to 90°C within half an hour, after 2.5 hours of reaction, add a small amount of sodium ethylate dropwis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com