Method for converting fluorine-containing function particle resin molecule

A particle and resin technology, applied in the field of functional fluorine-containing polymer materials, can solve the problems of mixing impurities, long hydrolysis time, complicated process, etc., and achieve the effect of excellent proton exchange function and shortening hydrolysis transformation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

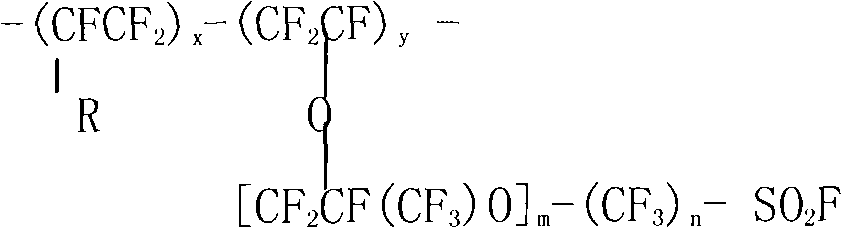

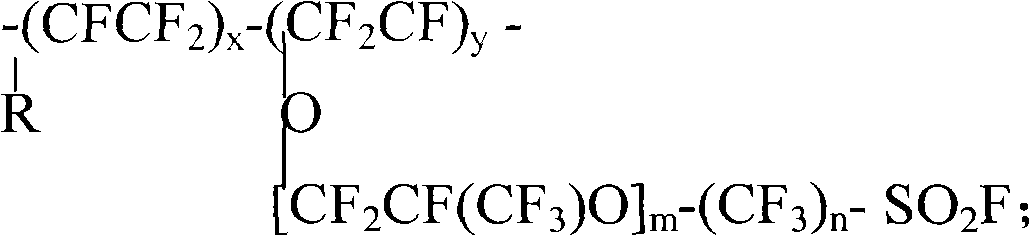

Image

Examples

Embodiment 1

[0037]Add 1 kg of sulfonic acid granular resin and 2 kg of KOH aqueous solution with a mass concentration of 25% in a glass-lined reactor. Control the reaction temperature to hydrolyze at 105° C. for 8 hours, and wash with deionized water for 2 to 3 times. Drain the deionized washing water and add HNO with a mass concentration of 30% 3 2 kg of aqueous solution was reacted for 2 hours, and the acidification reaction temperature was 85° C., and then the granular resin was washed with deionized water. After drying, the sulfonic acid granular resin with high cleanliness was obtained. The equivalent weight was 970g / mol and the residual amount of metal iron ion was 45PPb.

Embodiment 2

[0039] Add 1 kg of sulfonic acid granular resin and 2 kg of NaOH aqueous solution with a mass concentration of 30% in a glass-lined reactor. Control the reaction temperature to hydrolyze at 95° C. for 6 hours, and wash with deionized water for 2 to 3 times. Put clean deionized washing water, add mass concentration of 20% H 2 SO 4 3 kg of aqueous solution was reacted for 2 hours, and the acidification reaction temperature was 90° C., and then the granular resin was washed with deionized water. After drying, the sulfonic acid granular resin with high cleanliness was obtained. The equivalent weight was 1050g / mol, and the residual amount of metal iron ion was 30PPb.

Embodiment 3

[0041] Add 1 kg of sulfonic acid granular resin and 4 kg of NaOH aqueous solution with a mass concentration of 10% in a glass-lined reactor. Control the reaction temperature to hydrolyze for 10 hours at 120° C., and wash with deionized water for 2 to 3 times. Drain the deionized washing water, add 3 kg of HCL aqueous solution with a mass concentration of 15%, react for 1 hour, the acidification reaction temperature is 70 ° C, and then wash the granular resin with deionized water. After drying, the sulfonic acid granular resin with high cleanliness was obtained, and its equivalent weight was tested to be 1100g / mol, and the residual amount of metal iron ions was 37PPb.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com