Starch-based biodegradable environment-friendly plastic

A technology for degrading plastic and starch, applied in the field of environmentally friendly plastic products, can solve the problems of white pollution and trouble of plastic products, and achieve the effect of low cost, wide distribution, and improved value-added transformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention aims to provide a biostarch degradable plastic masterbatch. The masterbatch is composed of the following components by weight ratio: 70-80% of refined starch, 7-10% of toughening agent, 0.5%-2% of initiator, 4%-7% of modifier, and 1% of plasticizer -3%, lubricating processing aid 3% -6%.

[0017] Among them, the toughening agent is ethylene-vinyl acetate copolymer or POE or M-LLDPE; the initiator is dicumyl peroxide; the modifier is a mixture of stearic acid and maleic anhydride; the plasticizer is ethylene Glycol or glycerin or sorbitol; the lubricating processing aid is white oil or PE wax.

[0018] The content of stearic acid in the modifier accounts for 3%-5% of the total content, and the content of maleic anhydride accounts for 1-2% of the total content.

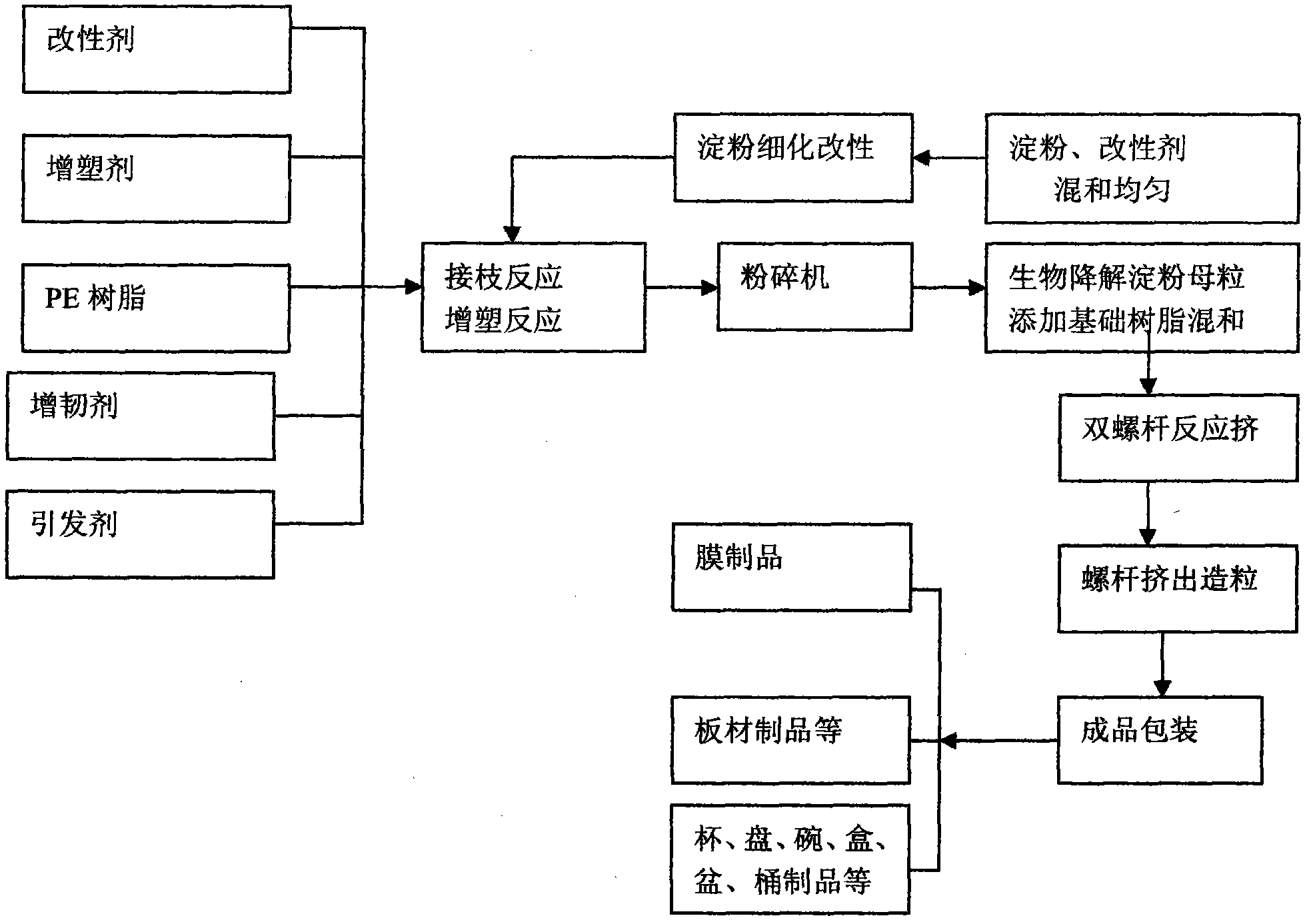

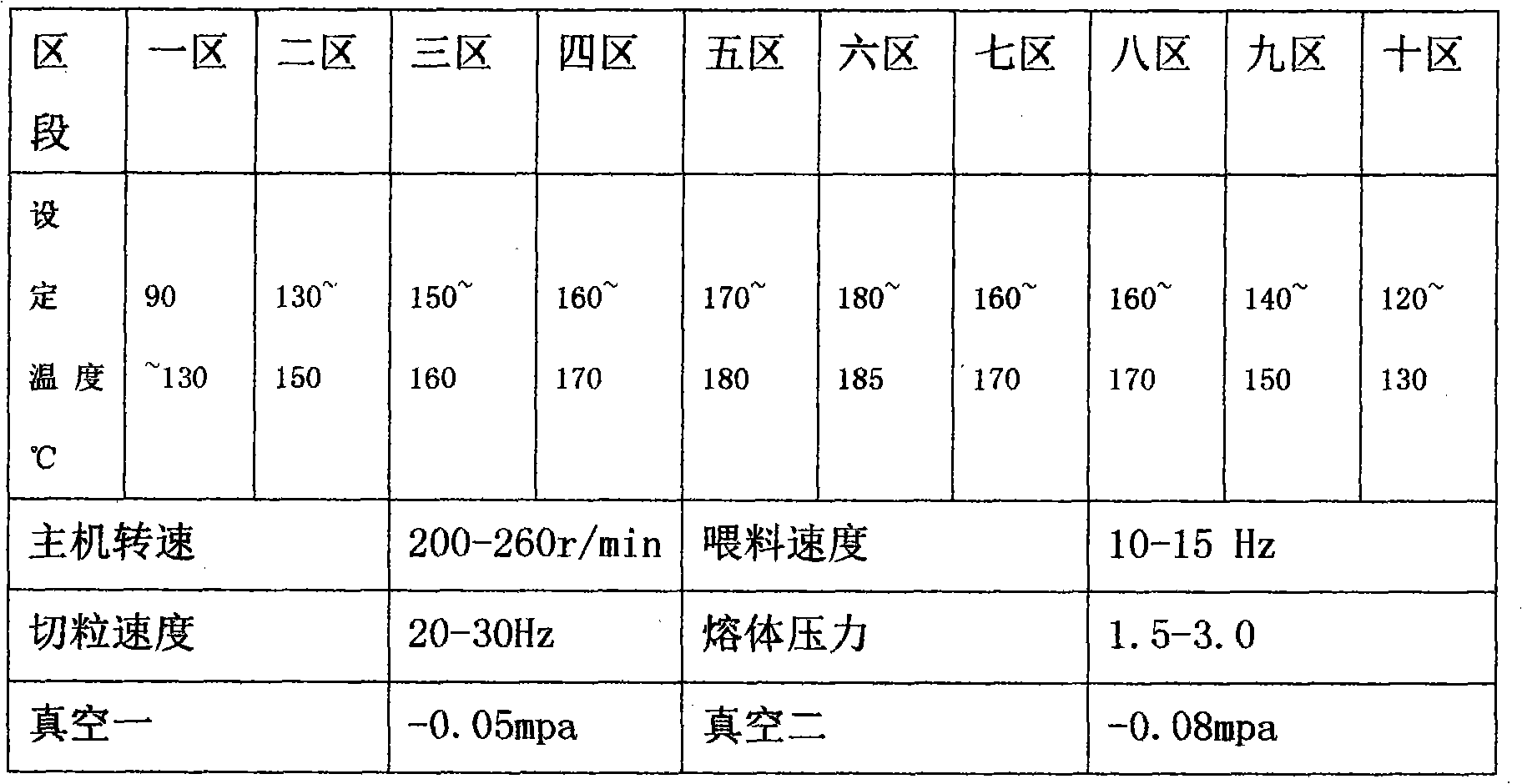

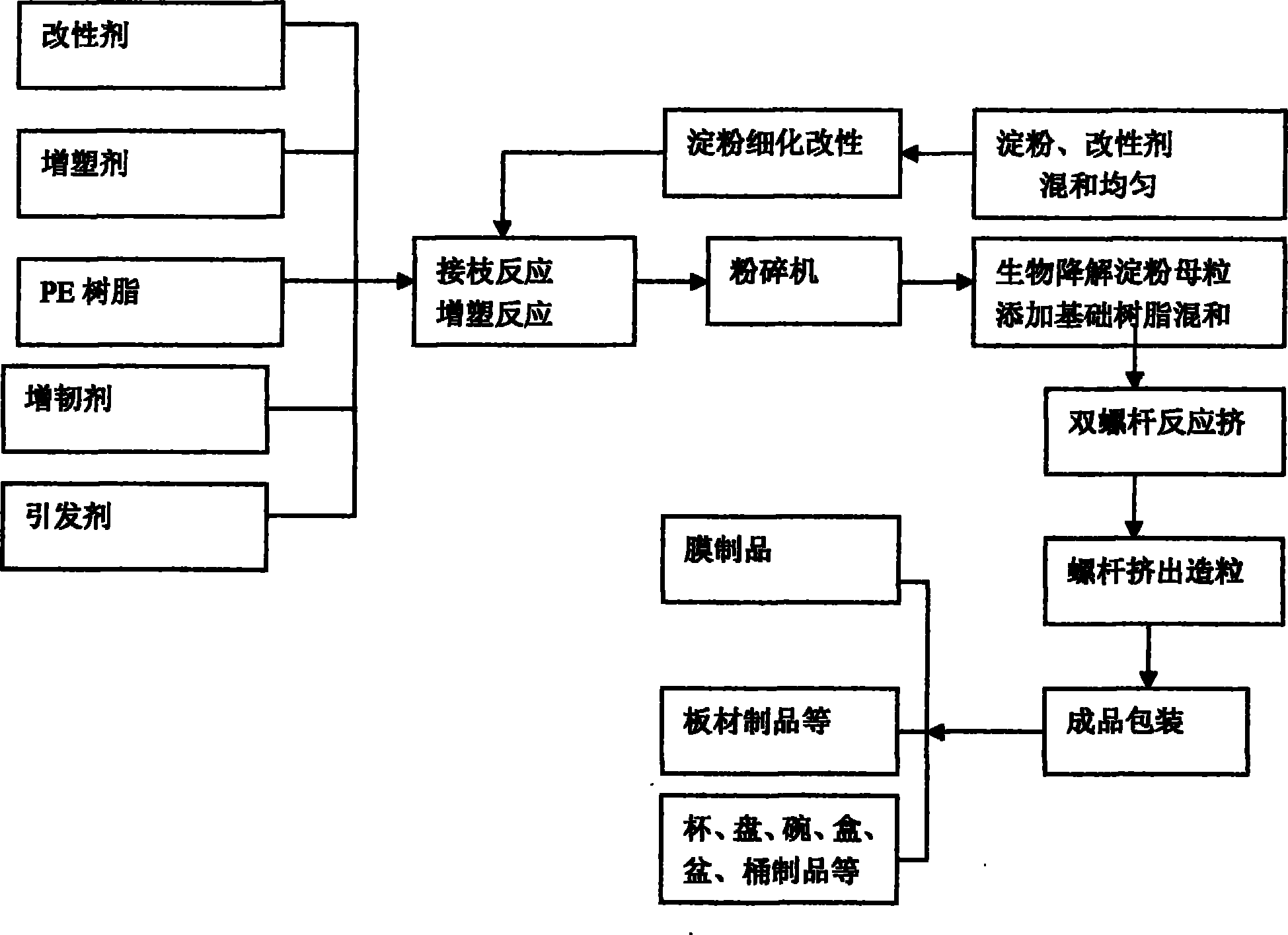

[0019] The production method of aforementioned biological starch degradable plastic masterbatch, it comprises the following steps:

[0020] Starch refinement process, starch high-speed mixing pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com