Photochromic film as well as preparation method and application thereof

A photochromic film and photochromic dye technology, applied in optics, optical components, optical components, etc., can solve problems such as inability to convert colors, attract dye particles to each other, and lose color conversion capabilities, so as to achieve product profit improvement and production efficiency. High efficiency, excellent anti-blue light performance and the effect of photochromic function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

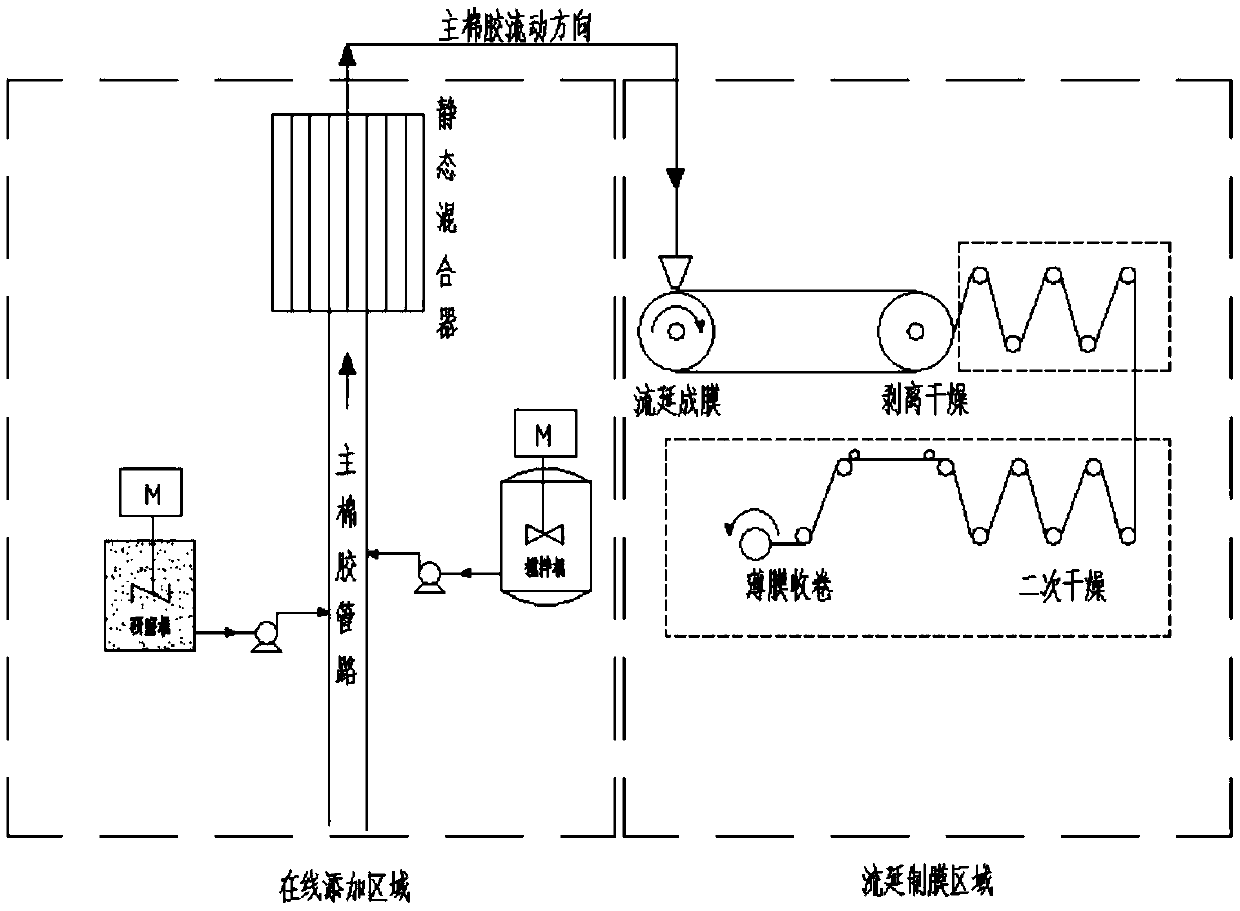

Method used

Image

Examples

Embodiment approach

[0028] As a preferred embodiment, the photochromic film includes the following components in parts by mass:

[0029] 50-70 parts of cellulose acetate; 8-10 parts of plasticizer; 2-4 parts of antioxidant; 2-3 parts of activator; 0.1-0.4 parts of heat-shrinkable additive; 0.8-1.0 parts of color-changing dye; 500-700 parts of solvent.

[0030] As a more preferred embodiment, the photochromic film includes the following components in parts by mass:

[0031] 50-70 parts of cellulose acetate; 8-10 parts of plasticizer; 2.5-3 parts of antioxidant; 2.5-3 parts of activator; 0.1-0.32 parts of heat-shrinkable additive; 0.8-1.0 parts of color-changing dye; 500-700 parts of solvent.

[0032] Preferably, the photochromic film includes the following components in parts by mass:

[0033] 60 parts of cellulose acetate; 8 parts of plasticizer; 2.5 parts of antioxidant; 3 parts of activator;

[0034] antioxidant

[0035] As an embodiment, the antioxidant includes hindered phenol antioxid...

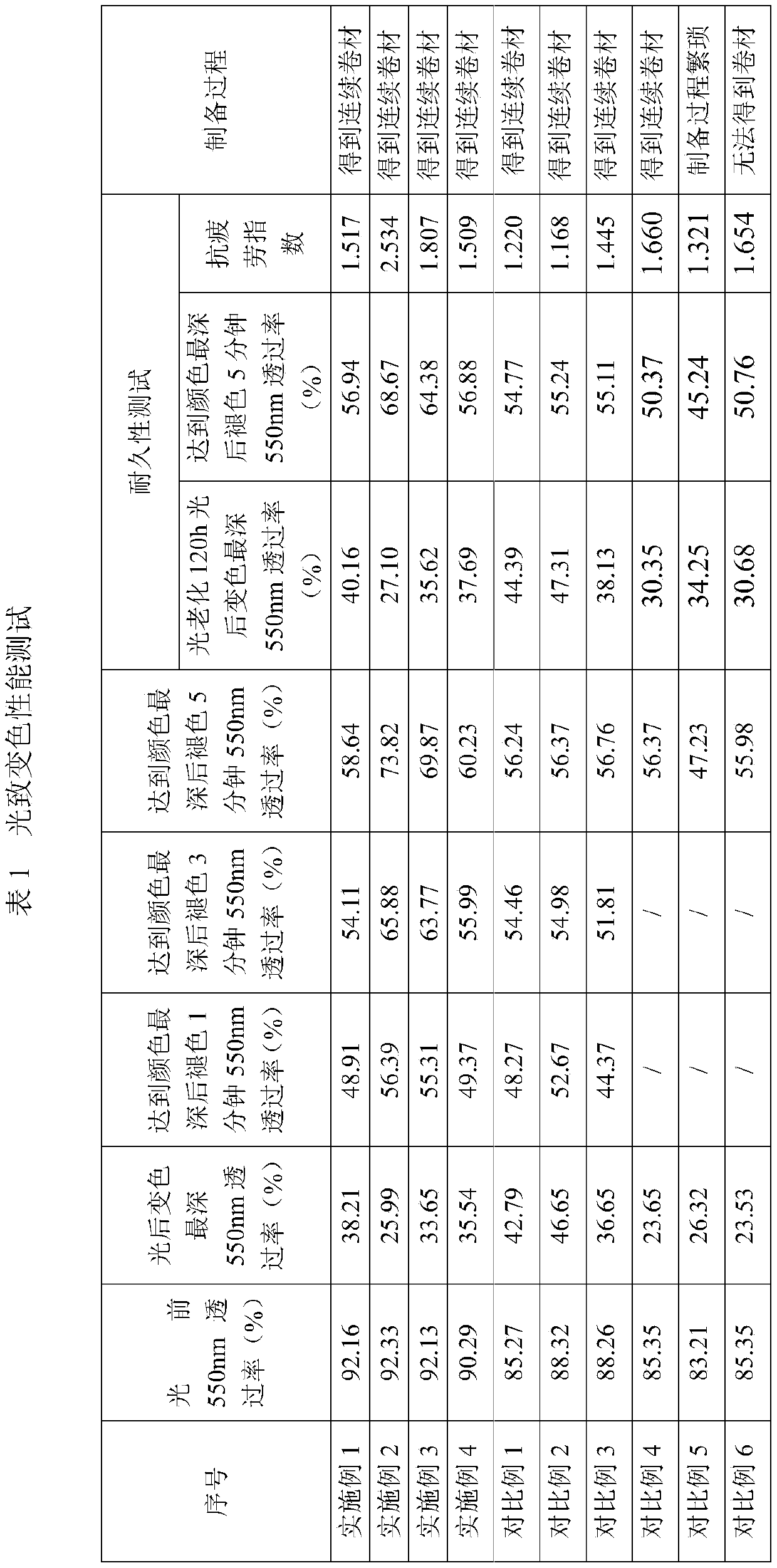

Embodiment 1

[0099] A photochromic film comprising the following components:

[0100] 60g of cellulose acetate; 6g of plasticizer; 3g of antioxidant; 1g of activator; 0.1g of heat-shrinkable additive;

[0101] The cellulose acetate is cellulose triacetate.

[0102] The plasticizer is dibutyl sebacate.

[0103] The antioxidant is antioxidant 1010.

[0104] The activator is glyceryl stearate.

[0105] The heat-shrinkable additive is Bi-Ni oxide containing La, La 2 Ni 2 o 5 .

[0106] The backlight integration agent is an azobenzene-containing mesoporous mica compound, N-ethyl-N-(2-chloroethyl)aniline.

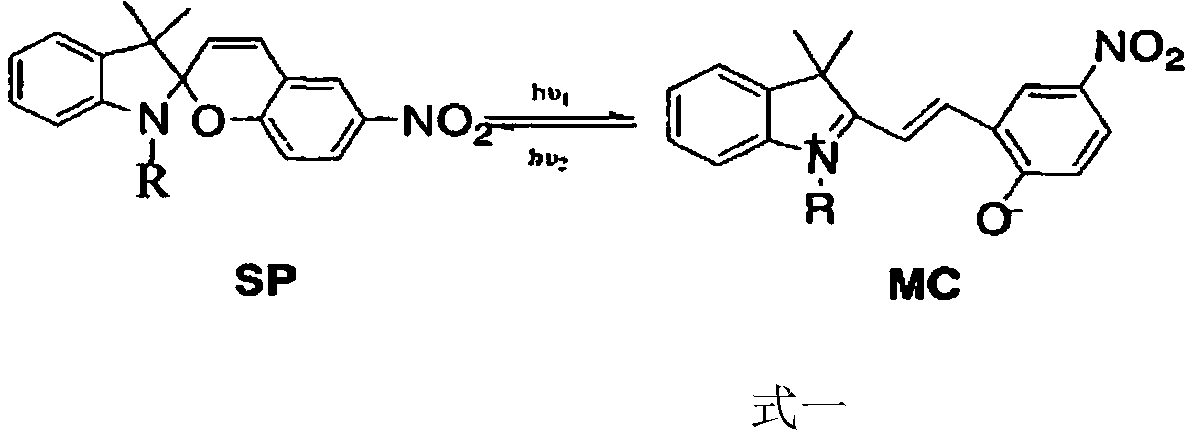

[0107] The photochromic dye is 1-(2-hydroxyethyl)-3,3-dimethylindoline-6'-nitrobenzospiropyran, and the CAS number is 16111-07-2.

[0108] The solvent includes a first solvent, a second solvent and a third solvent. The mass ratio of the first solvent, the second solvent and the third solvent is 2:1:1.

[0109] The first solvent, the second solvent and the third solvent are all mixed s...

Embodiment 2

[0116] A photochromic film comprising the following components:

[0117] 60g of cellulose acetate; 8g of plasticizer; 2.5g of antioxidant; 3g of activator; 0.32g of heat-shrinkable additive;

[0118] The cellulose acetate is cellulose triacetate.

[0119] The plasticizer is benzene polyester W-23-S.

[0120] The antioxidant is antioxidant 1010.

[0121] The activator is glycerol triacetate.

[0122] Described heat-shrinkable additive is with embodiment 1.

[0123] The backlight integration agent is the same as in Example 1.

[0124] Described photochromic dye is with embodiment 1.

[0125] The solvent includes a first solvent, a second solvent and a third solvent. The mass ratio of the first solvent, the second solvent and the third solvent is 2:1:1.

[0126] The first solvent, the second solvent and the third solvent are all mixed solvents of dichloromethane and methanol, and the mass ratio of the dichloromethane to methanol is 95:5.

[0127] The preparation method of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com