Hydrodynamic inclined-wire stock discharge box

A headbox, hydraulic technology, used in the paper industry, can solve the problems of fiber flocculation, slow pulp speed, fiber floating or sinking, etc., to achieve good uniformity and air permeability, less floor space, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

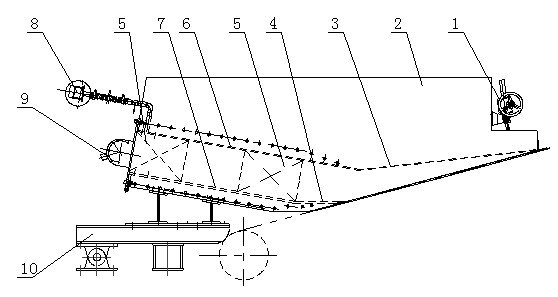

[0025] Example 1 Production of single-layer hydraulic inclined-wire headbox and dry bag paper

[0026] Such as figure 1 As shown, the single-layer hydraulic inclined wire headbox is composed of an adjustment mechanism 1, a side plate 2, an upper lip plate 3, a lower lip plate 4, a damping element 5, a top plate 6, a bottom plate 7, a banner dilution water device 8, and a section expander 9 And support 10 constitutes. The expander 9 is fixed on the pulp inlet side of the box; the adjustment mechanism 1 is fixed on the upper lip 3 of the box; the banner dilution water device 8 is fixed on the top plate 6 of the box; the box is connected to the upper part of the support 10 through a flange, The lower part of the support is installed on the inclined wire frame through the hinge chain, and the headbox is rotated by external force to adjust the angle of the headbox and the distance between the headbox and the inclined wire.

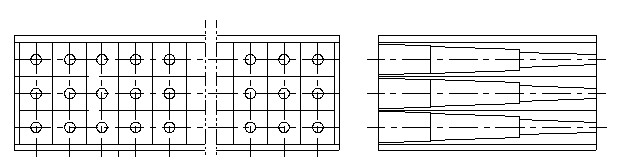

[0027] Such as figure 2 As shown, the damping element...

Embodiment 2

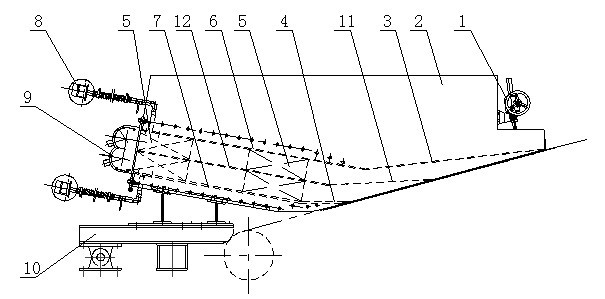

[0031] Example 2 Double-layer hydraulic type inclined wire headbox and papermaking of tea filter paper

[0032] Such as image 3 As shown, the double-layer hydraulic inclined wire headbox is composed of an adjustment mechanism 1, a side plate 2, an upper lip plate 3, a lower lip plate 4, a damping element 5, a top plate 6, a bottom plate 7, a banner dilution water device 8, and a section expander 9 , Support 10, floating sheet 11 and partition 12 constitute. The main difference between it and the single-layer hydraulic headbox is that there are two sets of expander and horizontal dilution water device. The horizontal dilution water device of the upper layer of slurry is fixed on the top plate of the box body; On the bottom plate of the box; there are two groups of damping elements along the slurry feeding direction of each layer of slurry. The two layers of slurry are separated by a partition. Float up and down to adjust the pressure balance of the two layers of slurry.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com