Multi-row hole thermal insulation building block reinforcing bar masonry wall system

A technology for thermal insulation blocks and masonry walls, applied in the direction of thermal insulation, walls, building components, etc., can solve the problems of immaturity, easy falling off, and easy cracking and damage of outer leaf walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

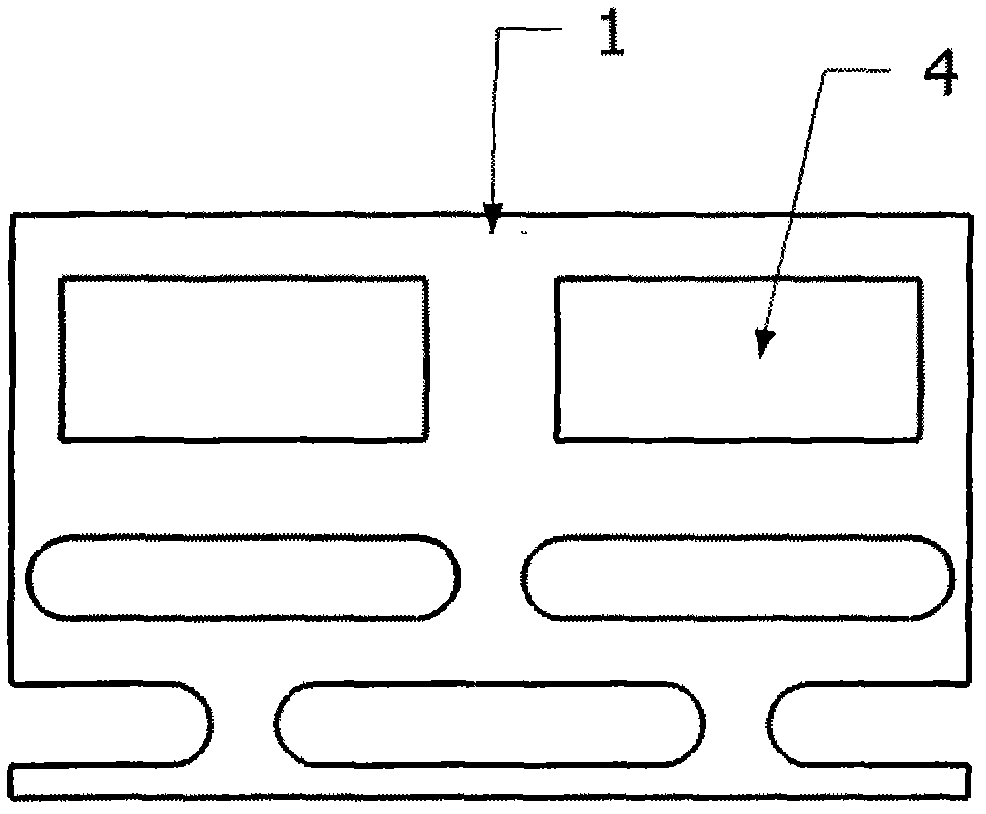

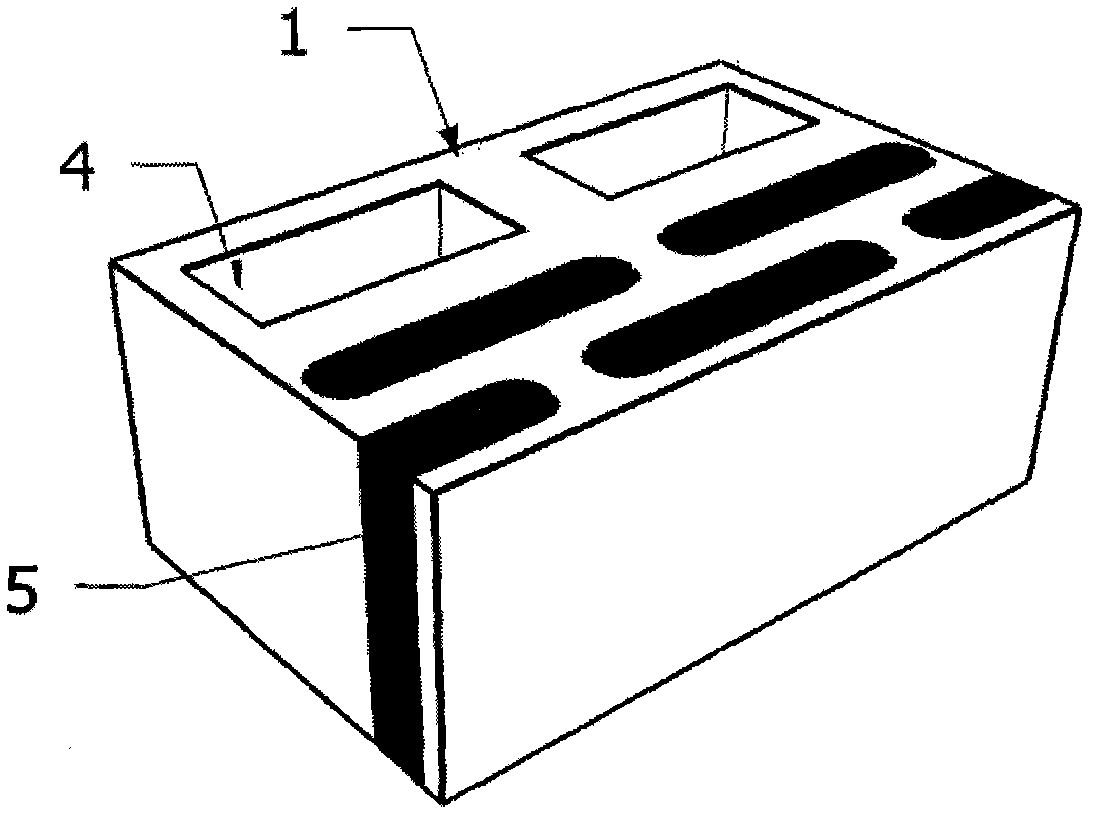

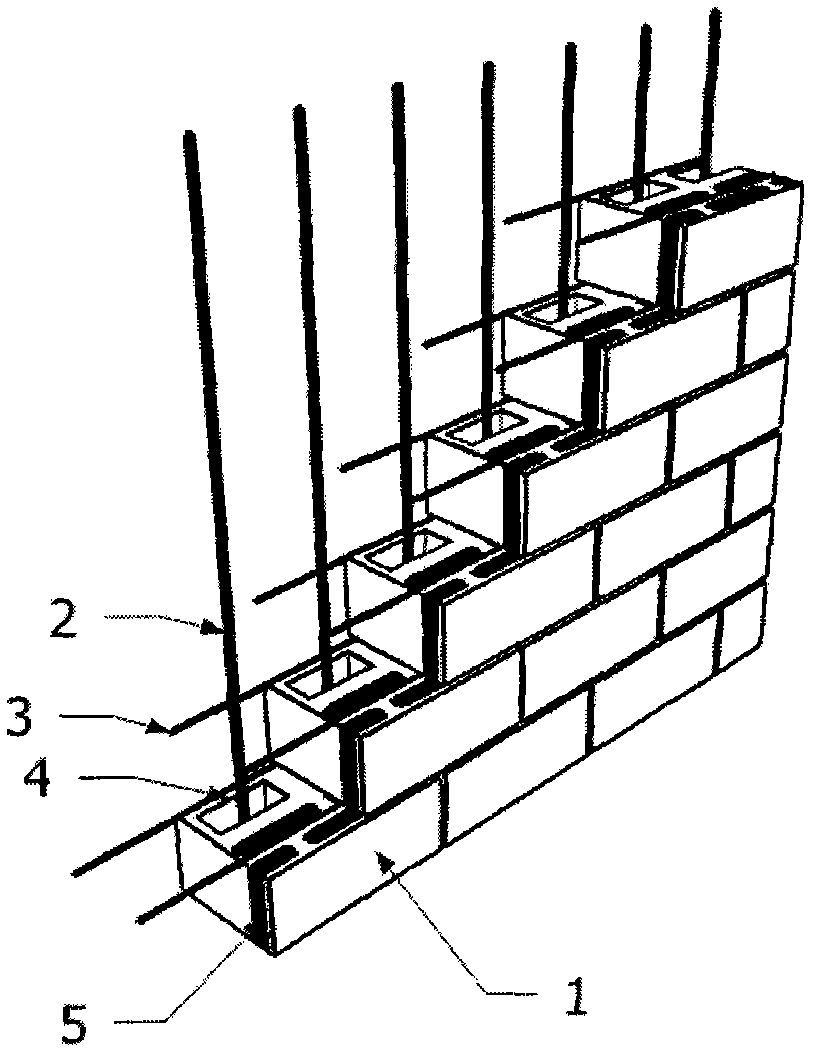

[0016] see figure 1 , figure 2 , image 3 , the length × width × height of the block is 390mm × 290mm × 190mm, the first row of holes is rectangular, and the remaining holes are oblate. The masonry method is staggered joint masonry. Before the masonry, the oblate holes are filled with thermal insulation materials. Then use this kind of masonry to build the wall. During the masonry process, pay attention to ensure that the upper and lower holes are aligned. Insert vertical steel bars into the holes where the cored concrete is poured, and pour the cored concrete.

Embodiment 2

[0018] see Figure 4 , the length × width × height of the block is 390mm × 290mm × 190mm, the first row of holes is rectangular, and the remaining holes are oblate. The masonry method is joint masonry. Before the masonry, fill the oblate hole with thermal insulation material. Then use this kind of masonry to build the wall. During the masonry process, pay attention to ensure that the upper and lower holes are aligned. Insert vertical steel bars into the holes where the cored concrete is poured, and pour the cored concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com