Split twin-well pumping unit

A split-type, oil-pumping unit technology, which is used in the production of fluids, wellbore/well components, and earth-moving drilling, etc., can solve the problems of difficult to adjust the position of the oil well support, limited use environment, inconvenient maintenance, etc., to achieve the speed torque Stable, simple circuit structure, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

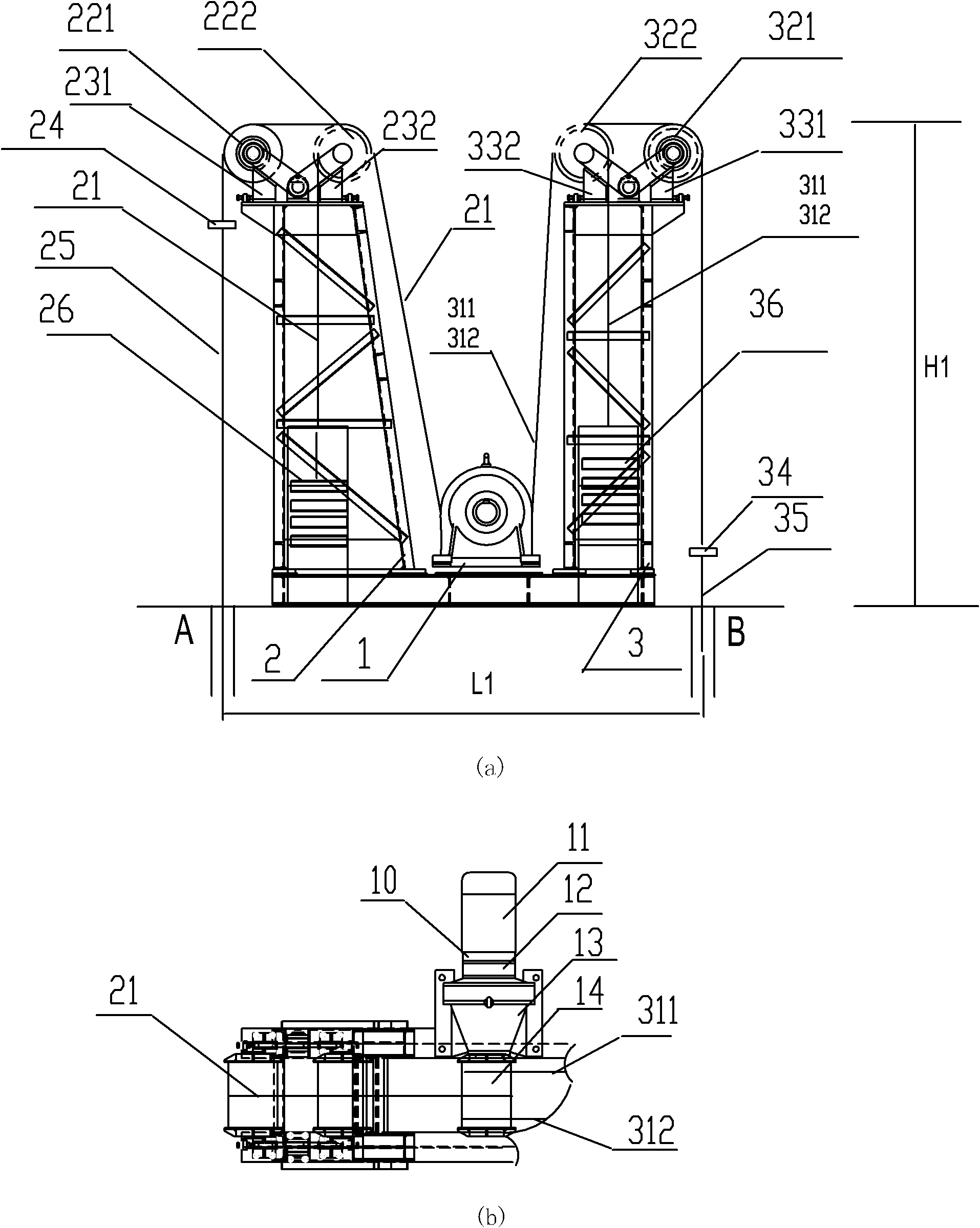

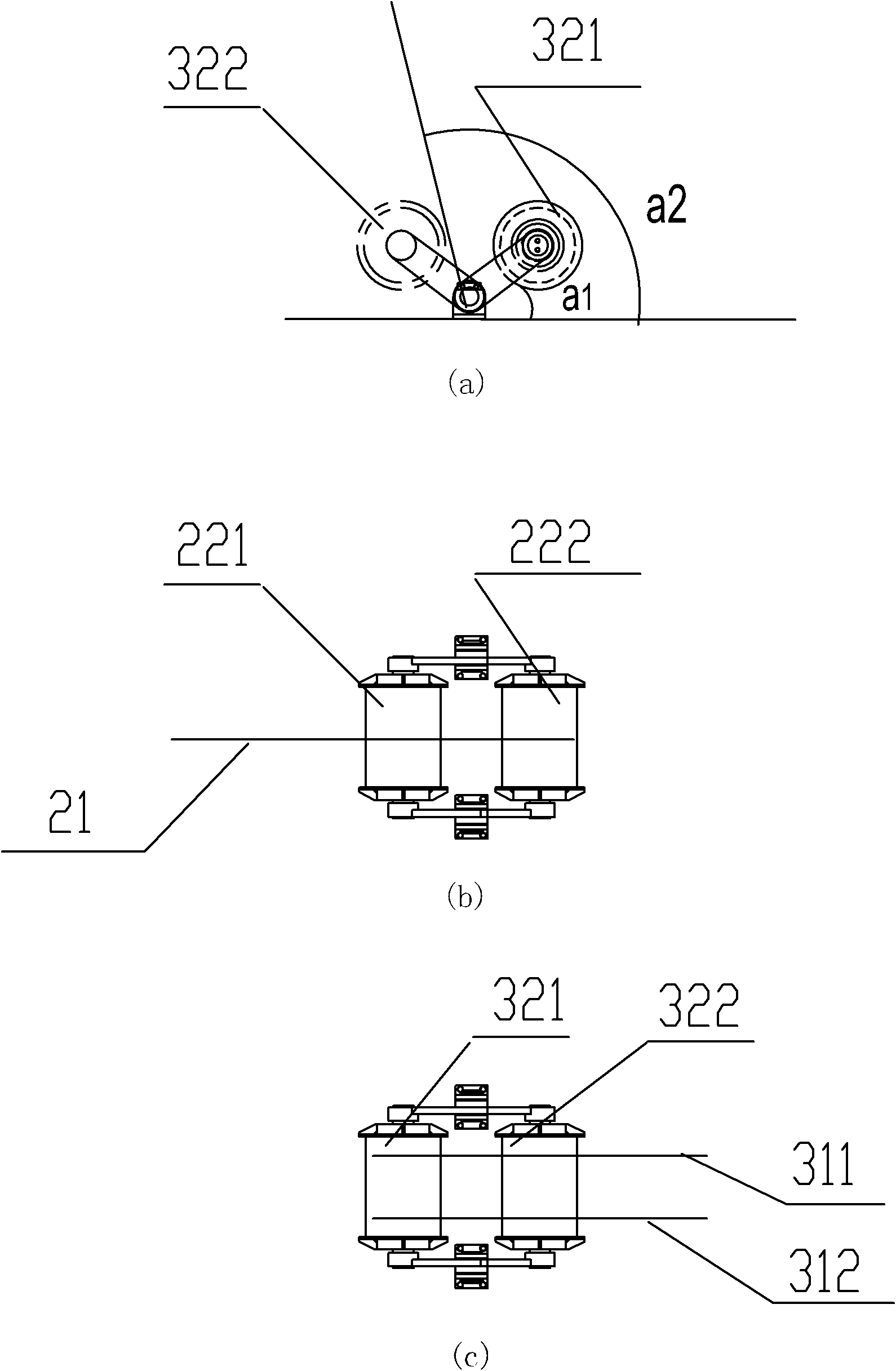

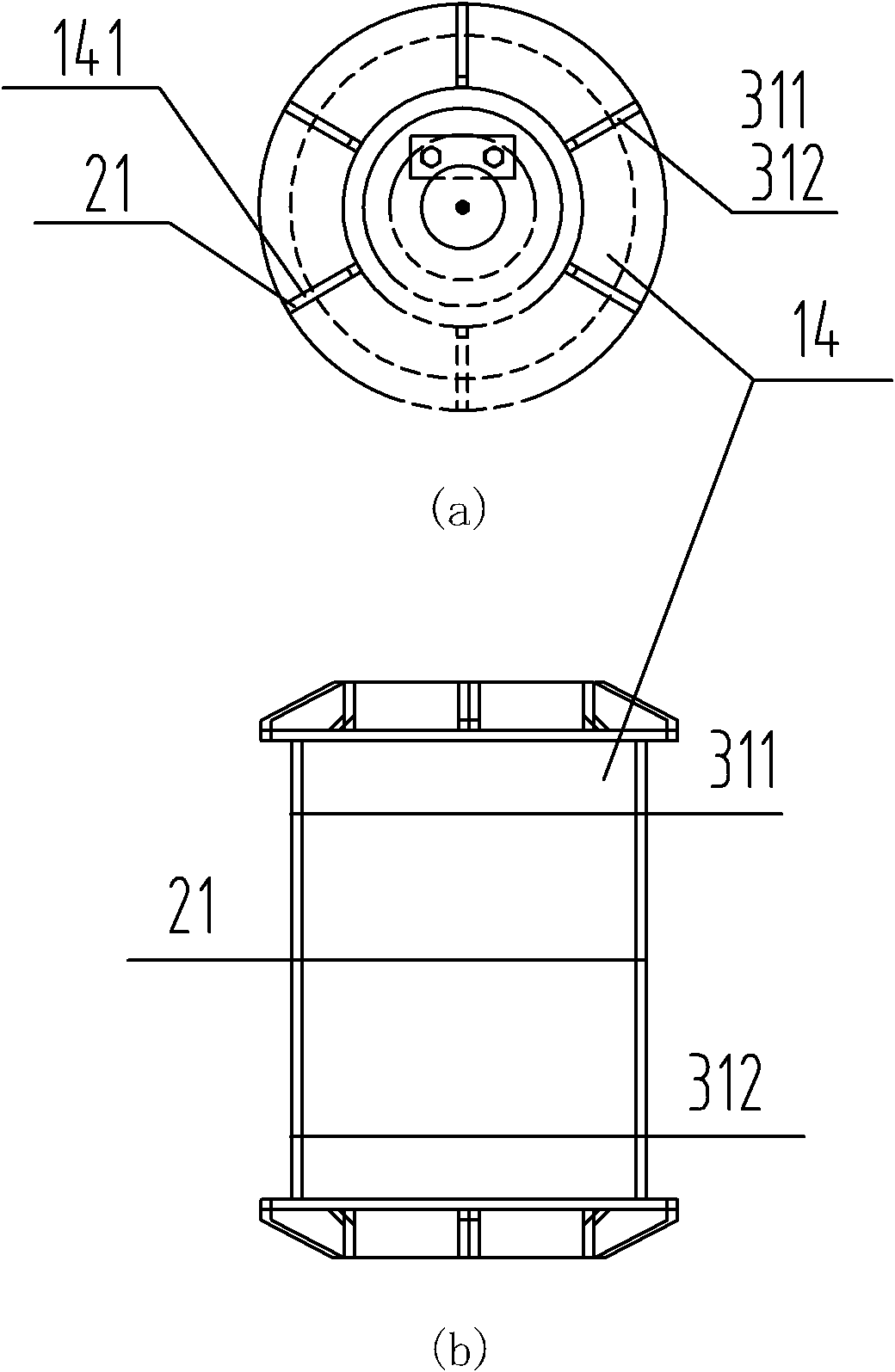

[0051] A split telescopic support type single and double well pumping unit, which is composed of a power base and an A / B support. The power base includes a motor, a coupling, a reducer, a power belt pressure roller, and an electro-hydraulic brake; the motor It is directly connected with the reducer, the motor adopts permanent magnet AC servo motor or switched reluctance speed regulating motor, the reducer adopts cycloid reducer, and the outer circle of the power belt pressure roller is equipped with symmetrical 1-3 pairs of belt slots The belt in well A is a single belt set at the center of the pressure roller of the power belt, the belt in well B is narrower than the belt in well A, and two belts are placed on both sides, staggered from the belt in well A, and the ends of the belts in well A and B are respectively stuck on the power belt. In the symmetrical groove of the belt pressure roller, the other end bypasses the counterweight drum and the oil pump drum and inserts into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com