Probe card and printed circuit board used for same

A printed circuit board and probe card technology, which is applied in the field of probe cards, can solve the problems of increasing overall cost expenditure, test error, noise interference, etc., and achieve the effects of good power integrity, cost saving and accuracy improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

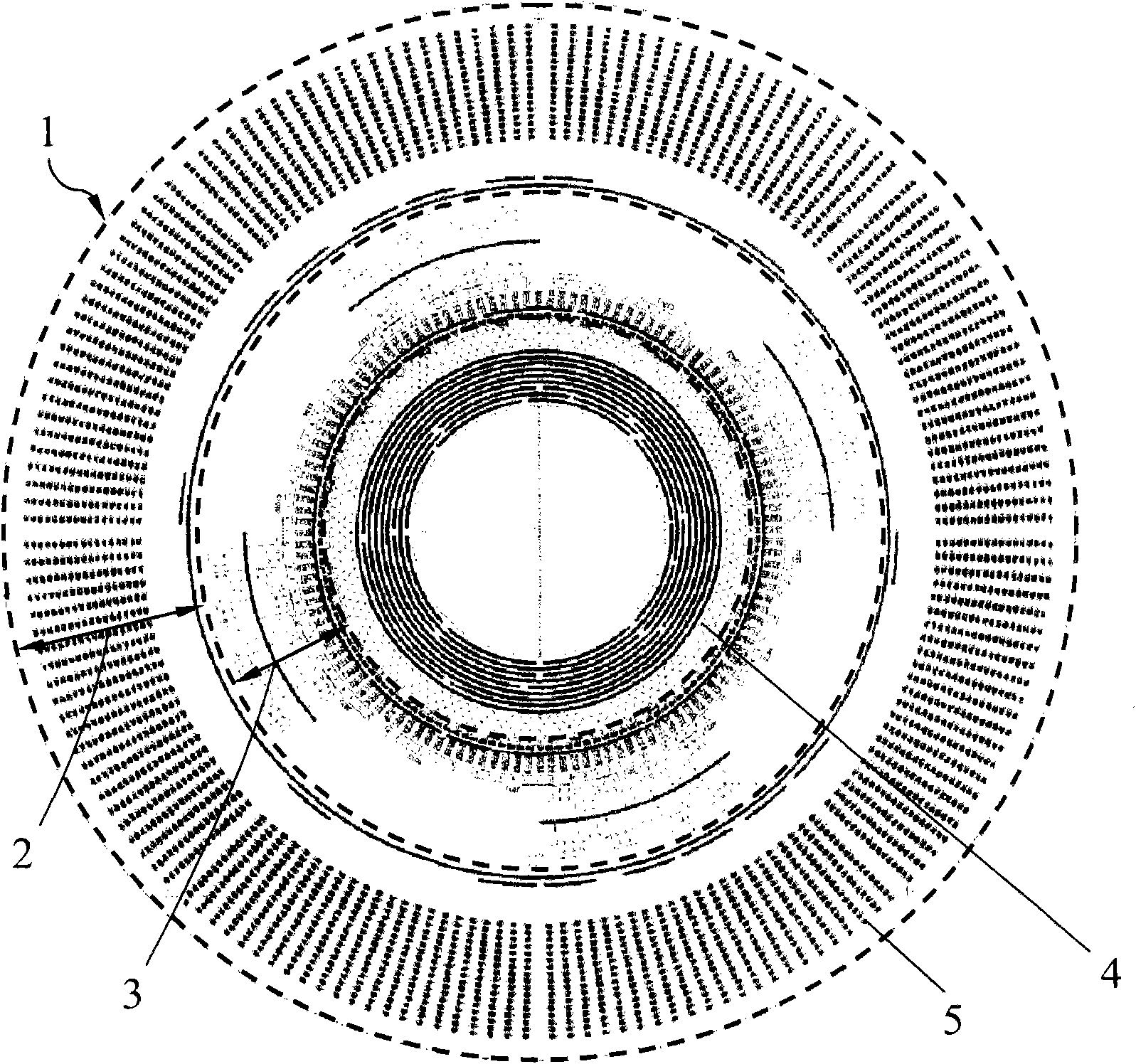

[0024] In an embodiment of the probe card of the present invention, the power plane is separated from the printed circuit board, and the probes are supplied with power by means of an external power plane or direct wire connection. Relevant detailed description and technical contents of the present invention, now cooperate with accompanying drawing to illustrate as follows:

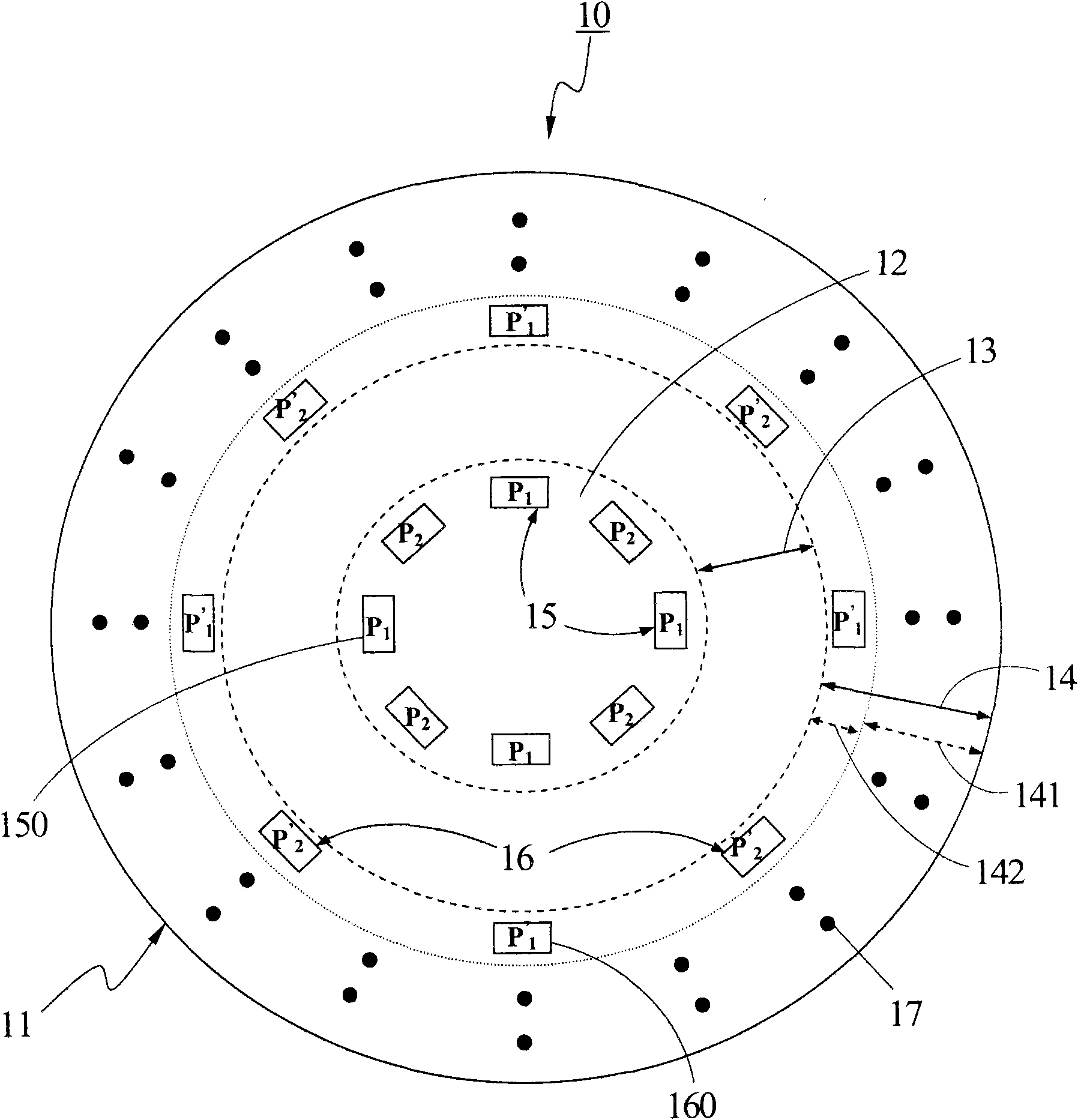

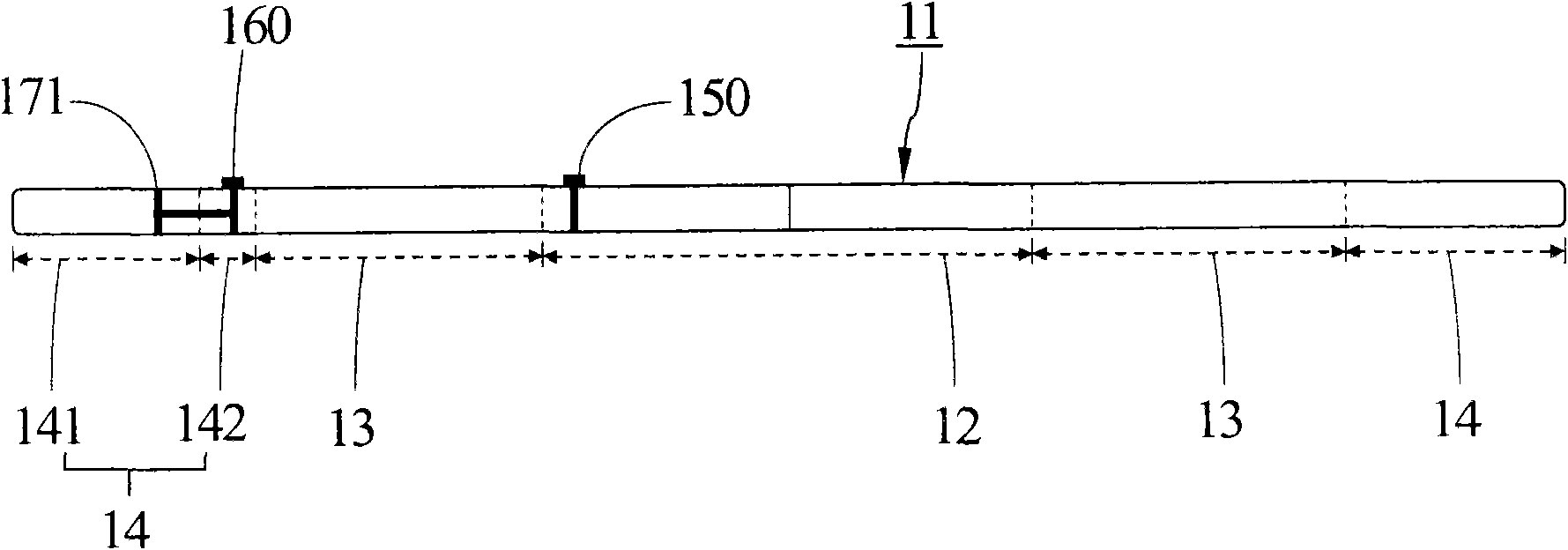

[0025] see Figure 2-1 and Figure 2-2 As shown, it is a schematic structural view and a schematic cross-sectional view of a printed circuit board 11 embodiment in the probe card 10 of the present invention. As shown in the figure: the printed circuit board 11 of this embodiment includes a solder joint area 12, a wiring area 13 and input area 14. Among them, the welding point area 12 is defined as the area where the printed circuit board 11 includes different pads and contacts for testing, power supply (power ring) near the inner ring; the input area 14 is defined as the printed circuit board 11 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com