Nitride light-emitting diode capable of enhancing carrier injection efficiency and manufacturing method thereof

A technology of light-emitting diodes and nitrides, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of low injection efficiency of electrons and holes, and achieve the effects of increasing the probability of tunneling, suppressing the tunneling effect, and reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1. If Figure 4 , using ordinary metal oxide vapor deposition (MOCVD) equipment, the substrate material 11 is a sapphire (0001) surface substrate; an initial growth layer 12 with a thickness of 20nm, and a GaN buffer layer 13 with a thickness of 1μm are sequentially grown on the substrate and a Si-doped n-type GaN electron injection layer 14 with a thickness of 2 μm;

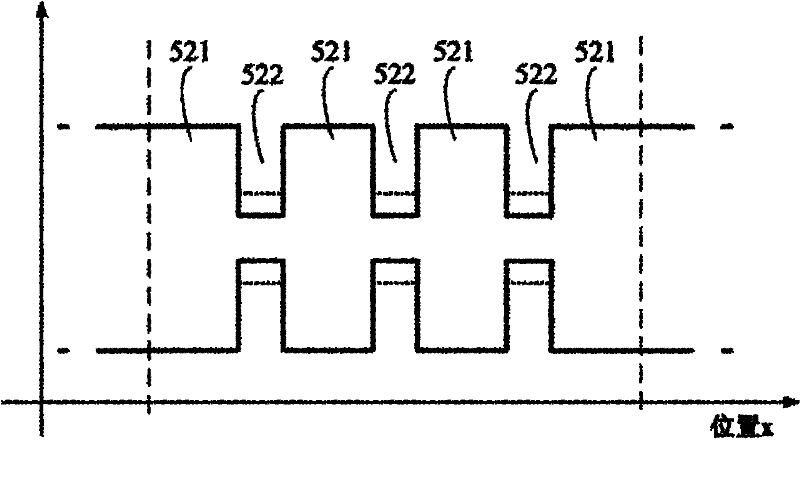

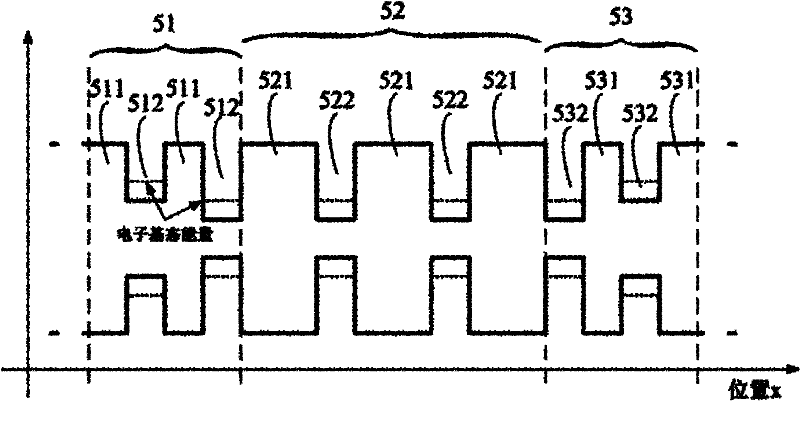

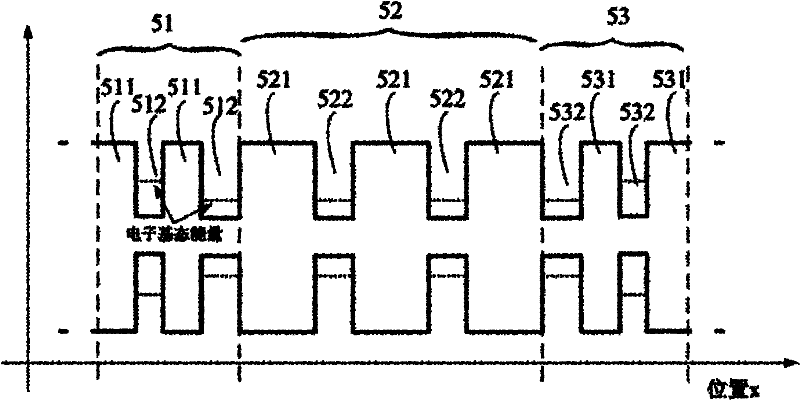

[0058] 2. On the basis of step 1, grow the coupled multi-quantum well active layer 15 through temperature control: sequentially grow 1) electron injection to strengthen the quantum well layer 51, and change the growth temperature of the InGaN quantum well to gradually change the In composition Large, shallow wells with low In composition are close to the n-type electron injection layer; 2) The compound quantum well region 52 in the middle keeps the growth temperature of the InGaN quantum well at a constant value and is equal to the temperature of the last quantum well in the electron-enhanced injection regi...

Embodiment 2

[0063] 1. As in Example 1, common metal oxide vapor deposition (MOCVD) equipment is used, and the substrate material 11 is a sapphire (0001) surface substrate; an initial growth layer 12 with a thickness of 20 nm is sequentially grown on the substrate, and the thickness is a GaN buffer layer 13 of 1 μm and a Si-doped n-type GaN electron injection layer 14 with a thickness of 2 μm;

[0064] 2. On the basis of step 1, grow the coupled multi-quantum well active layer 15 through thickness control: sequentially grow 1) electron injection to strengthen the quantum well layer 51, and change the growth time of the InGaN quantum well to gradually increase the well width. The narrow well is close to the n-type electron injection layer; 2) The compound quantum well region 52 in the middle keeps the growth time of the InGaN quantum well at a constant value and is equal to the time of electron strengthening injection for the last quantum well in the injection region. 3) Hole injection stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com