Thermal management system for power battery based on pulsating heat pipe

A heat management system and pulsating heat pipe technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of not considering the heat generation characteristics of batteries, heat recycling, heat dissipation priority, large thermal resistance, etc., and achieve simple structure , Large heat dissipation, solve the effect of high temperature heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

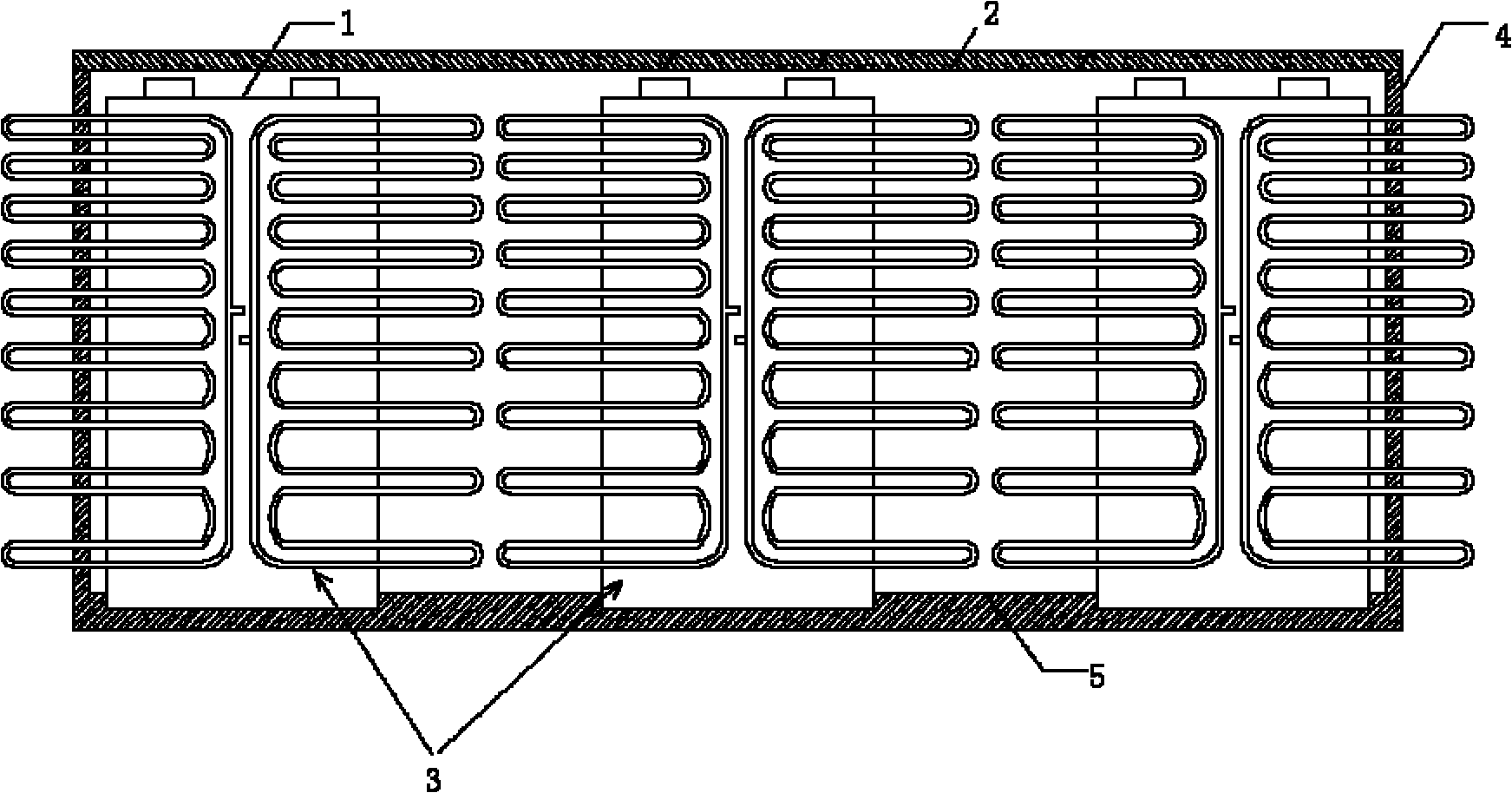

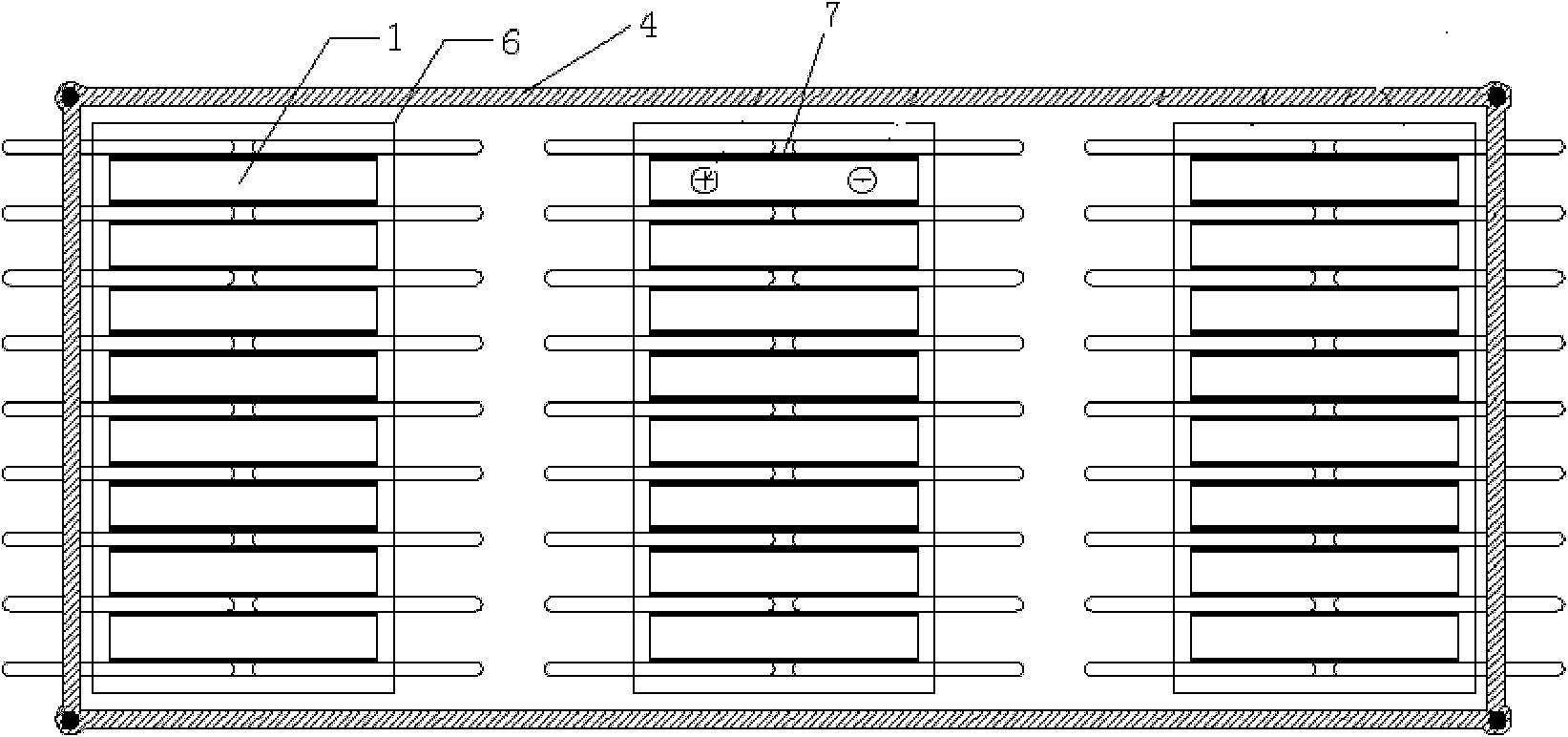

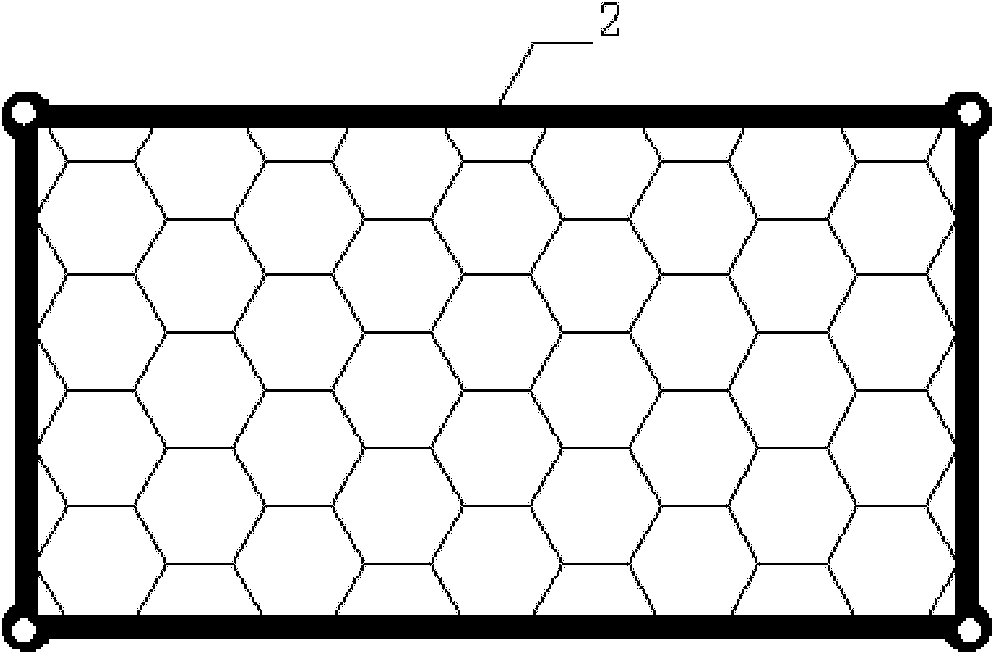

[0030] Such as figure 1 As shown, the power battery thermal management system based on the pulsating heat pipe of the present invention transfers the heat generated by the battery cells to the external environment of the battery module through the pulsating heat pipe 3 without additional power, so as to perform efficient thermal management on the battery. The system includes a module box 4 and a module box top cover 2. At least two battery cell casings 6 are placed in the module box 4, and at least two battery cells are placed in each battery cell casing 6. A battery module group composed of battery cells 1 connected in series or in parallel, each battery cell 1 is distributed with two pulsating heat pipes 3 bent back and forth in rows. Such as Figure 5 As shown, the pulsating heat pipe 3 is divided into an evaporation end 9 and a condensation end 8 , the evaporation end 9 is attached to the surface of the battery cell 1 , and the condensation end 8 protrudes from the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com