Method for refining hydrogen chloride gas

A hydrogen chloride gas and refining method technology, applied in the field of hydrogen chloride gas refining, can solve the problems of environmental pollution, large amount of by-product dilute hydrochloric acid, large steam consumption for heating, etc., solve the problems of follow-up treatment and environmental pollution, and facilitate industrial production , The effect of saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

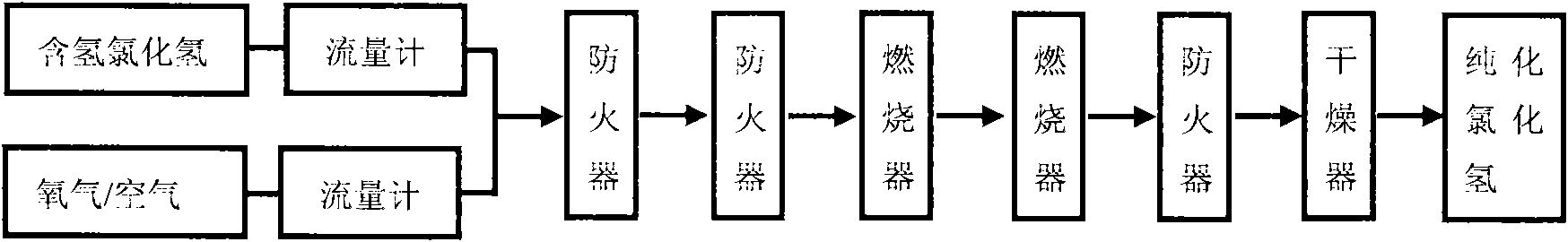

[0021] Example 1. The hydrogen chloride gas contains 13.2% (v / v) hydrogen as measured by the hydrogen on-line monitor, and 30L is measured by a flowmeter into the pipeline, and fully mixed with 2.2L of oxygen measured by the flowmeter in another pipeline, and the mixed gas enters a After passing through the second-level fire extinguisher, it enters the first-level burner for combustion reaction. After burning, it is determined to generate 0.17mol of water. The hydrogen chloride gas sampling analysis by the drier shows that the hydrogen content in the hydrogen chloride is 0.14% (v / v).

Embodiment 2

[0022]Example 2. The hydrogen chloride gas contains 13.5% (v / v) hydrogen as measured by the hydrogen on-line monitor, and 30L is measured by a flowmeter into the pipeline, and fully mixed with 2.3L of oxygen measured by the flowmeter in another pipeline, and the mixed gas enters a After passing through the second-level fire extinguisher, it enters the first-level burner for combustion reaction. After combustion, the gas enters the second-level burner to continue burning. After burning, it is determined to generate 0.18mol of water. The hydrogen chloride gas sampling analysis by the drier shows that the hydrogen content in the hydrogen chloride is 0.01% (v / v).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com