Preparation method of high-storage-stability polyester-type polyurethane prepolymer

A polyester polyurethane, storage-stable technology, applied in the field of polyurethane prepolymer preparation, can solve the problems of unstable performance of polyester polyurethane prepolymer and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

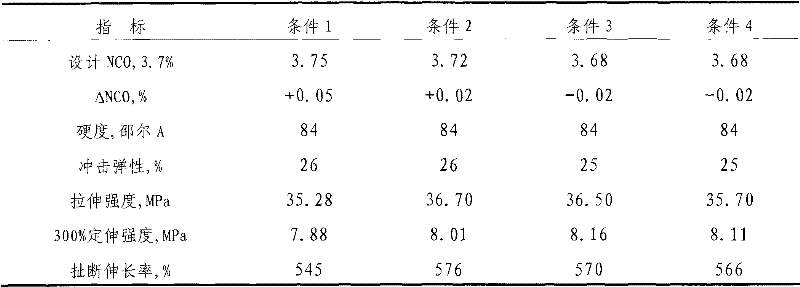

Embodiment 1

[0028] 1) Add 1000 grams of polyester polyol ODX-218 (Yantai Huada Chemical Industry Co., Ltd., Mn=2000) and 0.015 grams of metal ion complexing agent triethylamine into a mixing device, thermometer and dry nitrogen protection In the reactor of the device, heat and stir to raise the temperature. When the temperature rises to 120°C, stop nitrogen flow, start vacuum dehydration, vacuum degree 0.084MPa, dehydrate for 2 hours, then cool down to 50°C for use.

[0029] 2) The NCO% value of the polyurethane prepolymer is designed to be 3.7, and 177.1 grams of the required 2,4-toluene diisocyanate are added to a reactor equipped with a stirring device, a feed port, a thermometer and a dry nitrogen protection device, at 0.5 Add the materials in step 1) in 5 times within one hour, keep the reaction temperature at 50°C, react for 0.5 hours, heat up to 85°C at a heating rate of 10°C / 20 minutes, and maintain the reaction for 2 hours.

[0030] 3) Add 0.006 gram of polymerization inhibitor p...

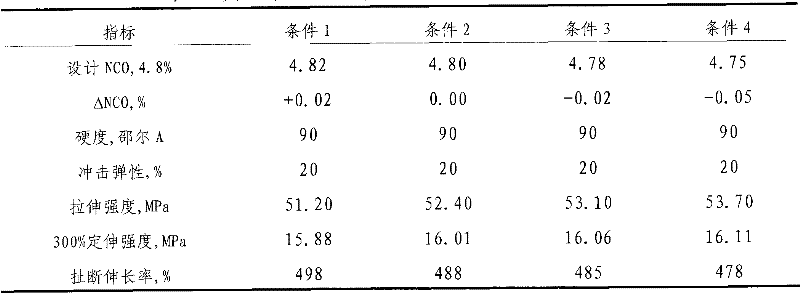

Embodiment 2

[0039] 1) Add 1000 grams of polyester polyol ODX-150 (Yantai Huada Chemical Industry Co., Ltd., Mn=1500) and 0.01 gram of metal ion complexing agent triisopropanolamine into a mixing device, thermometer and dry nitrogen In the reactor of the protection device, heat and stir to raise the temperature. When the temperature rises to 110°C, stop nitrogen flow, start vacuum dehydration, vacuum degree 0.086MPa, dehydrate for 2 hours, then cool down to 45°C for use.

[0040]2) The NCO% value of the polyurethane prepolymer is designed to be 4.8, and 239 grams of the required 2,4-toluene diisocyanate are added to a reactor equipped with a stirring device, a feed port, a thermometer and a dry nitrogen protection device, at 0.5 Add the materials in step 1) in 5 times within one hour, keep the reaction temperature at 45°C, react for 0.5 hours, heat up to 82°C at a heating rate of 10°C / 20 minutes, and maintain the reaction for 2 hours.

[0041] 3) Add 0.01 gram of polymerization inhibitor b...

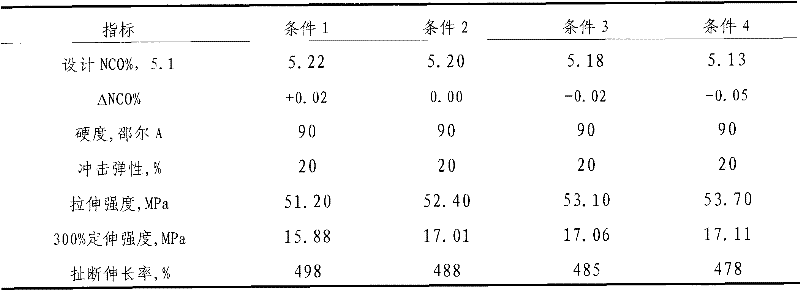

Embodiment 3

[0048] 1) 1000 grams of polyester polyol CMA-1024 (Yantai Huada Chemical Industry Co., Ltd., Mn=1000) and 0.008 grams of metal ion complexing agent disodium diamine tetraacetate are added to a mixing device, thermometer and In the reactor of the dry nitrogen protection device, heat and stir to raise the temperature. When the temperature rises to 115°C, stop nitrogen flow, start vacuum dehydration, vacuum degree 0.088MPa, dehydrate for 2 hours, then cool down to 40°C for use.

[0049] 2) The NCO% value of the polyurethane prepolymer is designed to be 5.1, and 312.5 grams of the required 2,4-toluene diisocyanate are added to a reactor equipped with a stirring device, a feed port, a thermometer and a dry nitrogen protection device, at 0.5 Add the materials in step 1) in 5 times within one hour, keep the reaction temperature at 40°C, react for 0.5 hours, heat up to 80°C at a heating rate of 10°C / 20 minutes, and maintain the reaction for 2 hours.

[0050] 3) Add 0.015 grams of poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com