Beam shaping device

A beam shaping and device technology, applied in optical components, optics, instruments, etc., can solve the problems of extremely high requirements for use methods and skills, high requirements for the stability of incident light sources, and insufficient uniformity. It has low requirements on using skills, is conducive to mass production, and has a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

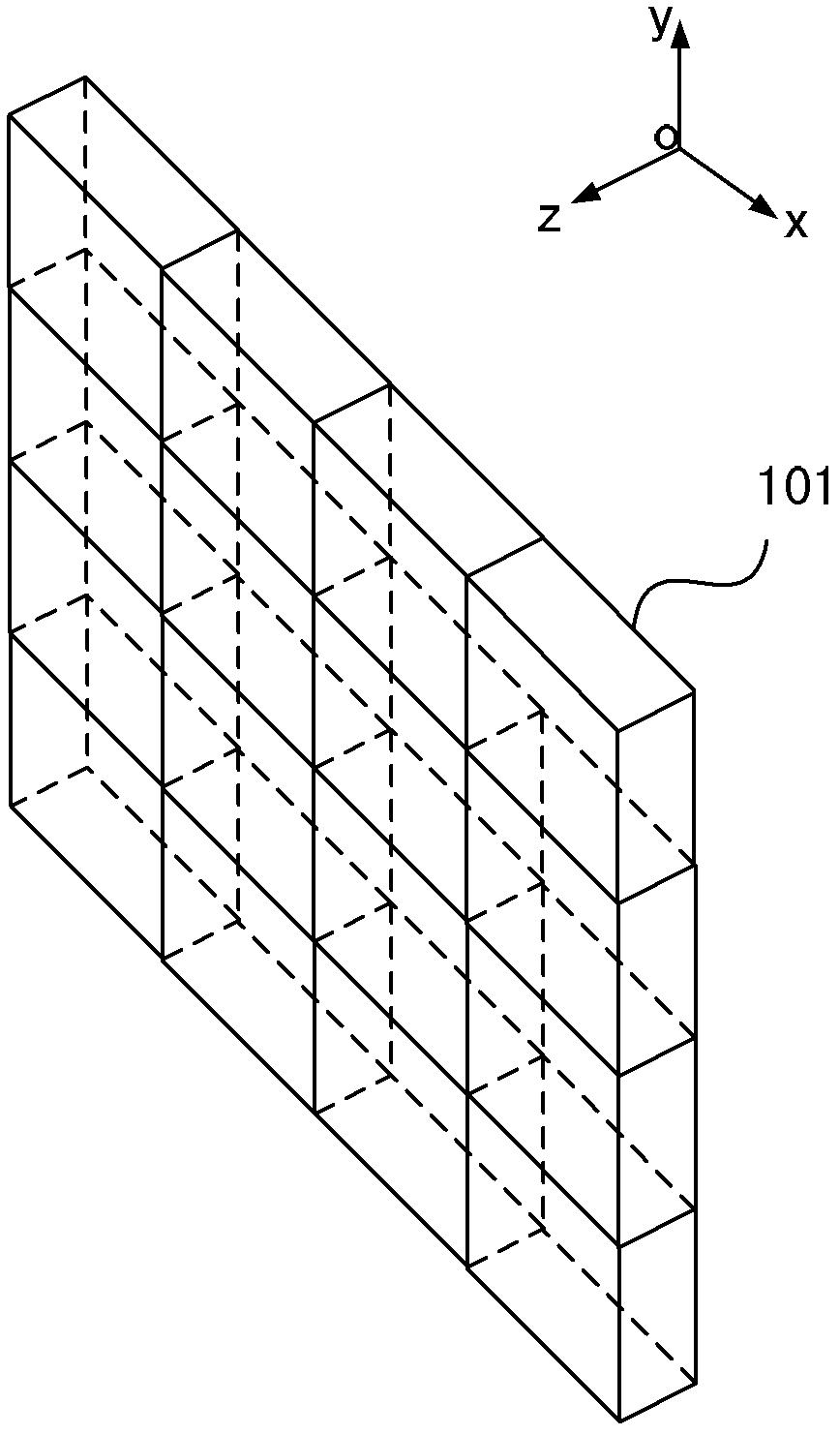

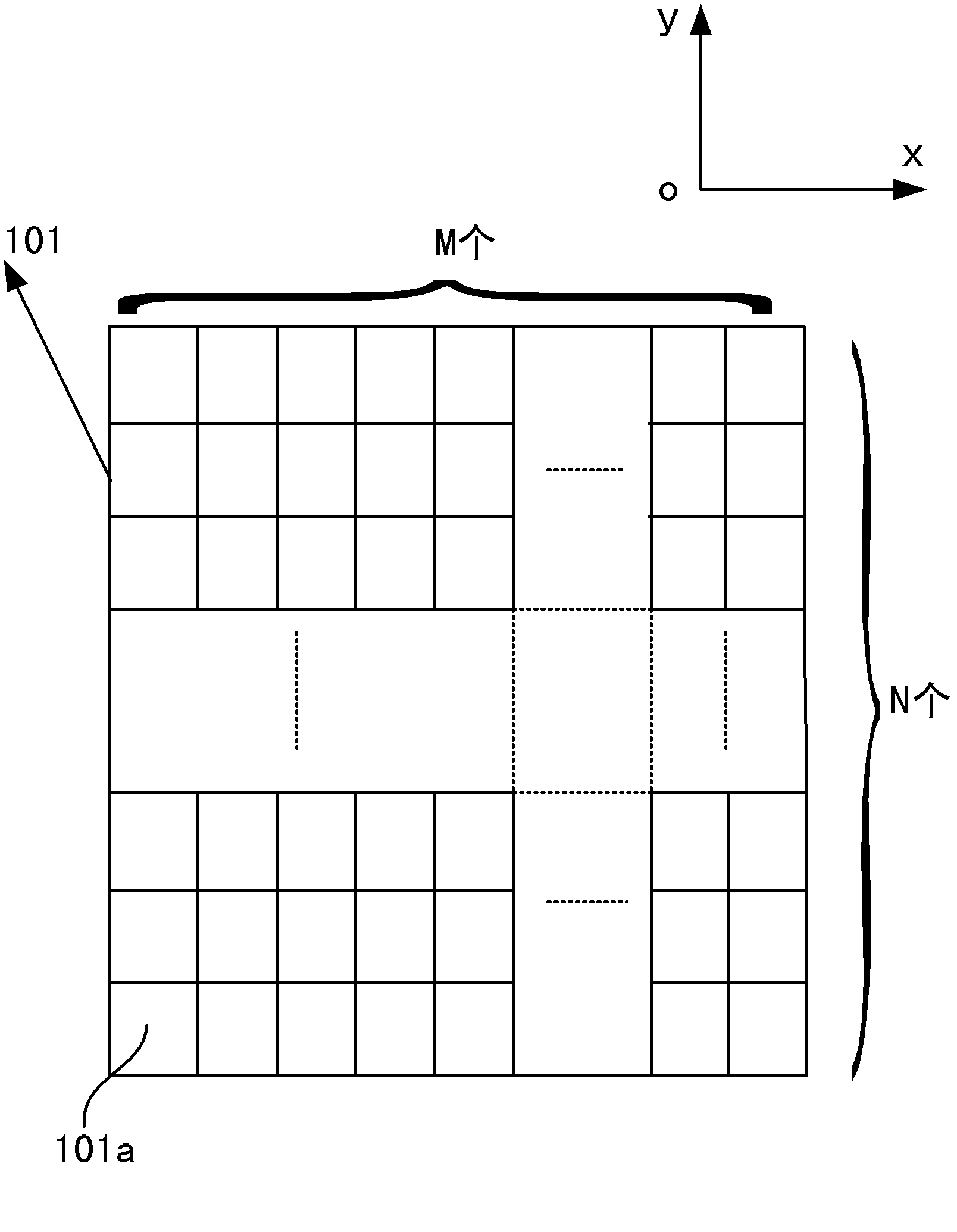

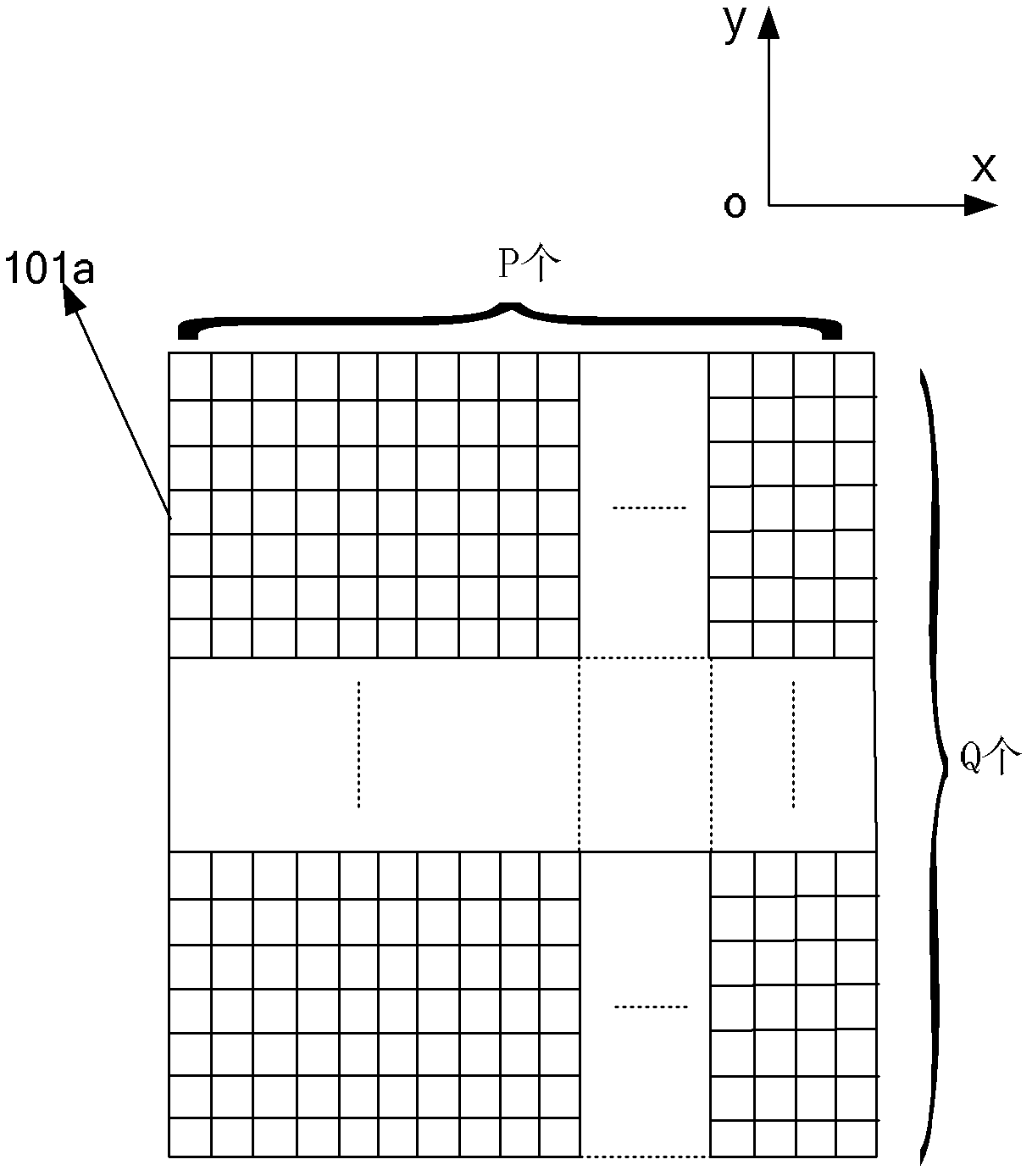

[0022] Figure 1a It is a schematic structural diagram of an array beam shaping device according to Embodiment 1 of the present invention, Figure 1b is a schematic cross-sectional view of the xoy plane structure of the beam shaping device according to Embodiment 1 of the present invention, Figure 2a It is a structural schematic diagram of the shaping unit of the present invention. One side surface of the working surface of the base 101 of the shaping device includes a plurality of shaping units 101a, the cross-section in the xoy plane of the shaping unit 101a is a rectangular structure, and the shaping units 101a are arrayed along the x-axis and the y-axis of the base 101 of the shaping device distribution, such as Figure 1b As shown, M columns of shaping units 101a (integer of M ≥ 1) are distributed along the x-axis of the base 101 of the shaping device, and N rows of shaping units 101a (integer of N ≥ 1) are distributed along the y-axis of the base of the shaping device....

Embodiment 2

[0030] Figure 5 It is a schematic cross-sectional view of the xoy plane of the beam shaping device according to Embodiment 2 of the present invention. The base 101 of the beam shaping device is circular, and the shaping units 101a inside it are rectangular and irregular in shape. Each shaping unit 101a is distributed in an array along the x-axis and the y-axis. There are tiny gaps between adjacent shaping units 101a. gap. The size of the shaping unit 101a is on the order of millimeters. M shaping units 101a (an integer of M≥1) are distributed along the x-axis, and N shaping units 101a (an integer of N≥1) are distributed along the y-axis, that is, the number of shaping units 101a in the x-axis and the y-axis The number can be 2 or 3 or more than 3, but it must be ensured that M and N are not 1 at the same time. When M=N=1, it is a common optical shaping unit. The image structure of the phase sub-unit in the shaping unit 101a is the same as the calculation method in the embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com