Compositions comrrising amlodipine and bisoprolol

A kind of technology of amlodipine base and amlodipine besylate, applied in the field of solid pharmaceutical compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

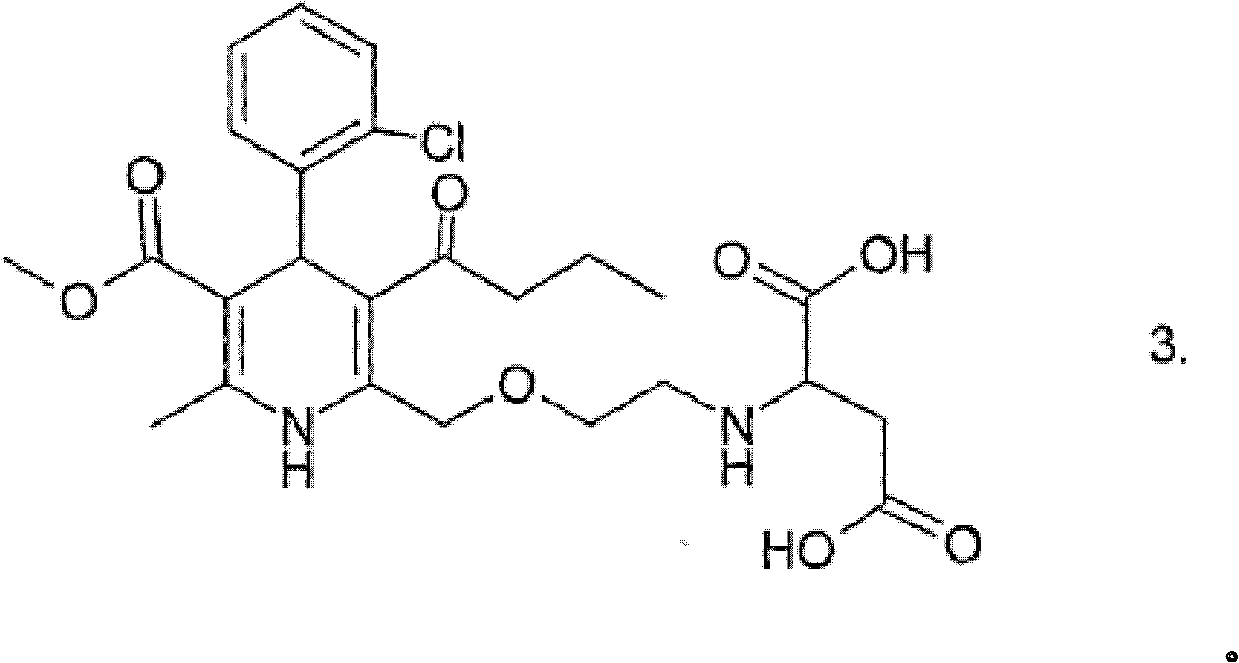

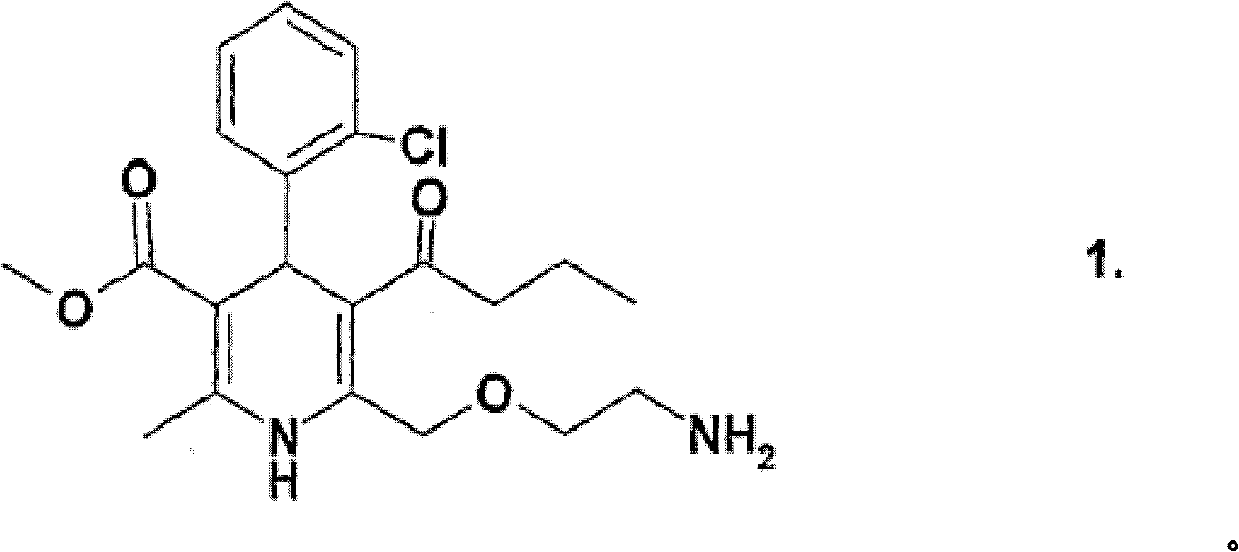

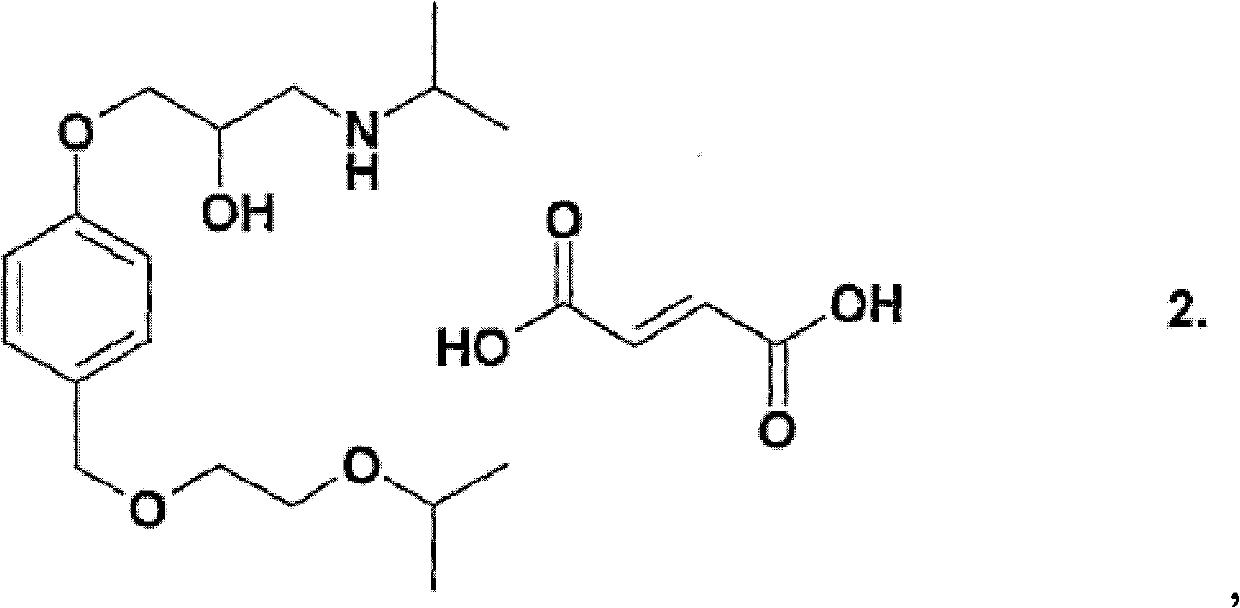

Image

Examples

Embodiment 1

[0103] Composition of 1000 tablets:

[0104]

[0105] method:

[0106] The two active ingredients were sieved through a 250 μm sieve and then homogenized with microcrystalline cellulose, sodium starch glycolate and colloidal silicon dioxide in a drum mixer for 10 minutes. Magnesium stearate was then added to the mixture and the resulting mixture was further homogenized for 2 minutes.

[0107] The homogenate was compressed into tablets having a weight of 305 mg using a tablet machine.

[0108] Tablets were packed into cold-formed OPA / AL / PVC composite foil blisters with a thickness of 130 μm and covered with aluminum foil with a thickness of 20 μm.

[0109] Tablets prepared according to Example 1 were checked for contaminants on the day of manufacture and after storage for 3 months at 40°C / 75% relative humidity as follows:

[0110]

[0111] Further quality data of the product of Example 1 are as follows:

[0112]

Embodiment 2

[0114] Composition of 1000 capsules:

[0115]

[0116] method:

[0117] The two active ingredients were sieved through a 250 μm sieve and then homogenized with microcrystalline cellulose, sodium starch glycolate and colloidal silicon dioxide in a drum mixer for 10 minutes. Magnesium stearate was then added to the powder mixture and the resulting mixture was homogenized for a further 2 minutes.

[0118] The homogenate is filled into capsules with a 47 mg filling using a tablet press.

[0119] Capsules were packed into cold-formed OPA / AL / PVC composite foil blisters with a thickness of 130 μm and covered with aluminum foil with a thickness of 20 μm.

[0120] On the day of production and after storage for 3 months at 40° C. / 75% relative humidity, the results of the contaminant inspection of the capsules prepared and packaged according to Example 2 were as follows:

[0121]

[0122] Reference example:

[0123] Composition of 1000 tablets:

[0124]

[0125] method:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com