Micromechanical component and method for the production thereof

A technology of micromechanical components and structures, applied in the field of manufacturing such components, can solve the problems of escaping gas, changing pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

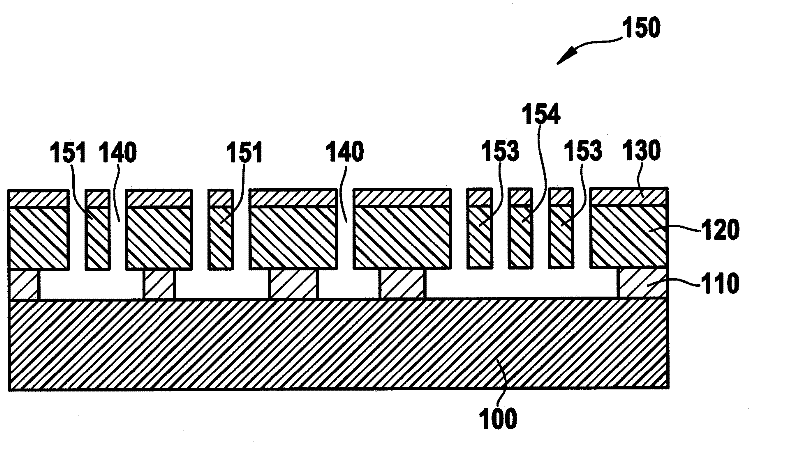

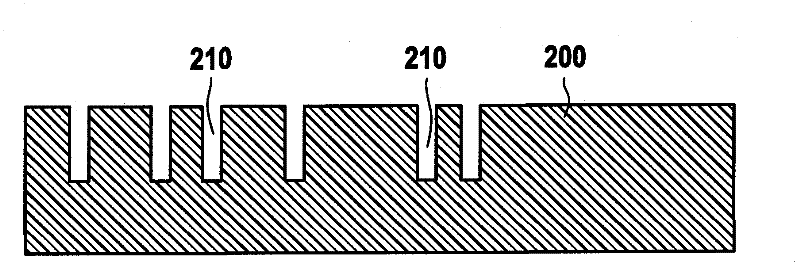

[0016] the following Figures 1 to 7 The production of a micromechanical component 300 is shown schematically, which can be used, for example, as an inertial sensor in a motor vehicle. During manufacture, processes and materials conventional in semiconductor technology can be used.

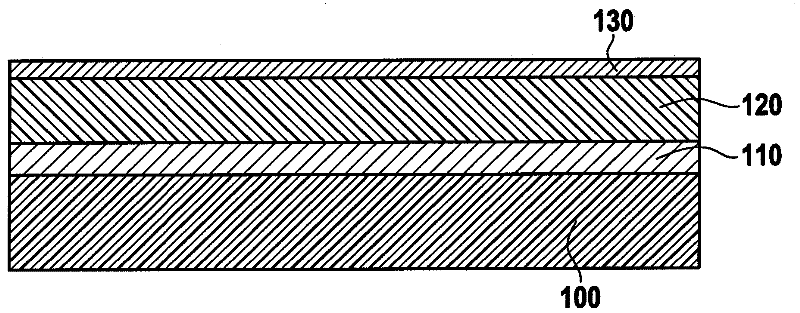

[0017] figure 1 and 2 The production of a functional substrate 100 with a micromechanical structure or MEMS structure 150 is shown for a component 300 , initially a substrate 100 is provided, which comprises, for example, a semiconductor material such as silicon. Substrate 100 may be a commonly used wafer having a diameter of, for example, 8 inches (200 mm).

[0018] Next on the substrate 100 as in figure 1 A sacrificial layer (Opferschicht) 110 is applied as shown in and a functional layer 120 is applied on this sacrificial layer 110 . The sacrificial layer 110 preferably comprises silicon oxide. The functional layer 120 may be a so-called epitaxial polysilicon layer, ie a polysilicon laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com