Exhaust gas purification system for diesel engines

A technology for diesel engine and exhaust gas purification, applied in engine components, combustion engines, machines/engines, etc., can solve problems such as space problems, achieve compact structure, improve rapid gasification, and large degrees of freedom.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

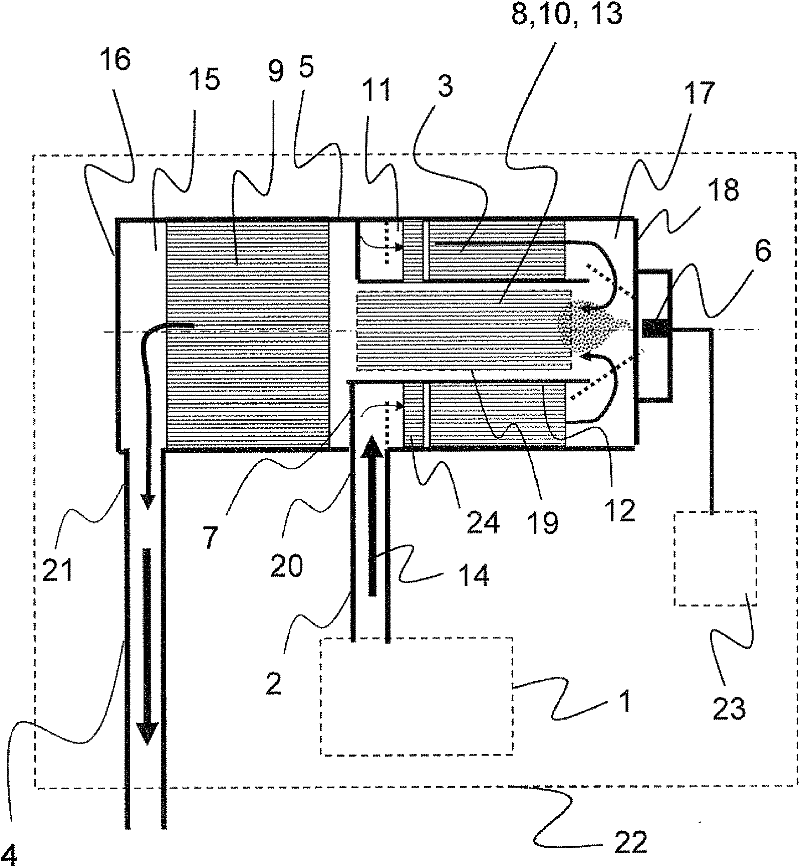

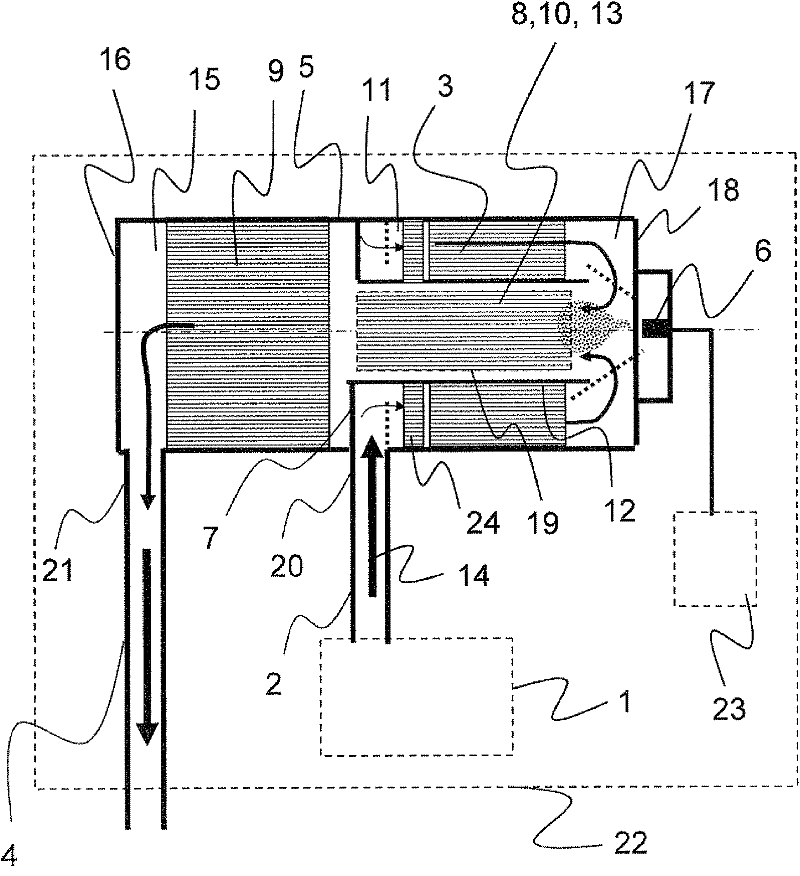

[0027] exist figure 1 The exhaust gas purification system shown in is used in particular for diesel engines of commercial vehicles. The power requirements of commercial vehicles are very high, while at the same time the consumption should be as low as possible. Carbon dioxide and water vapor are mainly produced during fuel combustion in each cylinder of a diesel engine, but the incomplete combustion makes unburned hydrocarbons, carbon monoxide, carbon black, and nitrogen oxides formed due to high combustion temperatures still exist in the exhaust substances, which are to be removed from the exhaust gas as completely as possible by means of the exhaust gas purification system according to the invention.

[0028] according to figure 1 The diesel engine 1 is connected to the casing 5 of the exhaust gas purification system through the exhaust pipe 2 . The exhaust pipe 2 opens approximately centrally on the outer circumference of the housing 5 into the region of the partition wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com