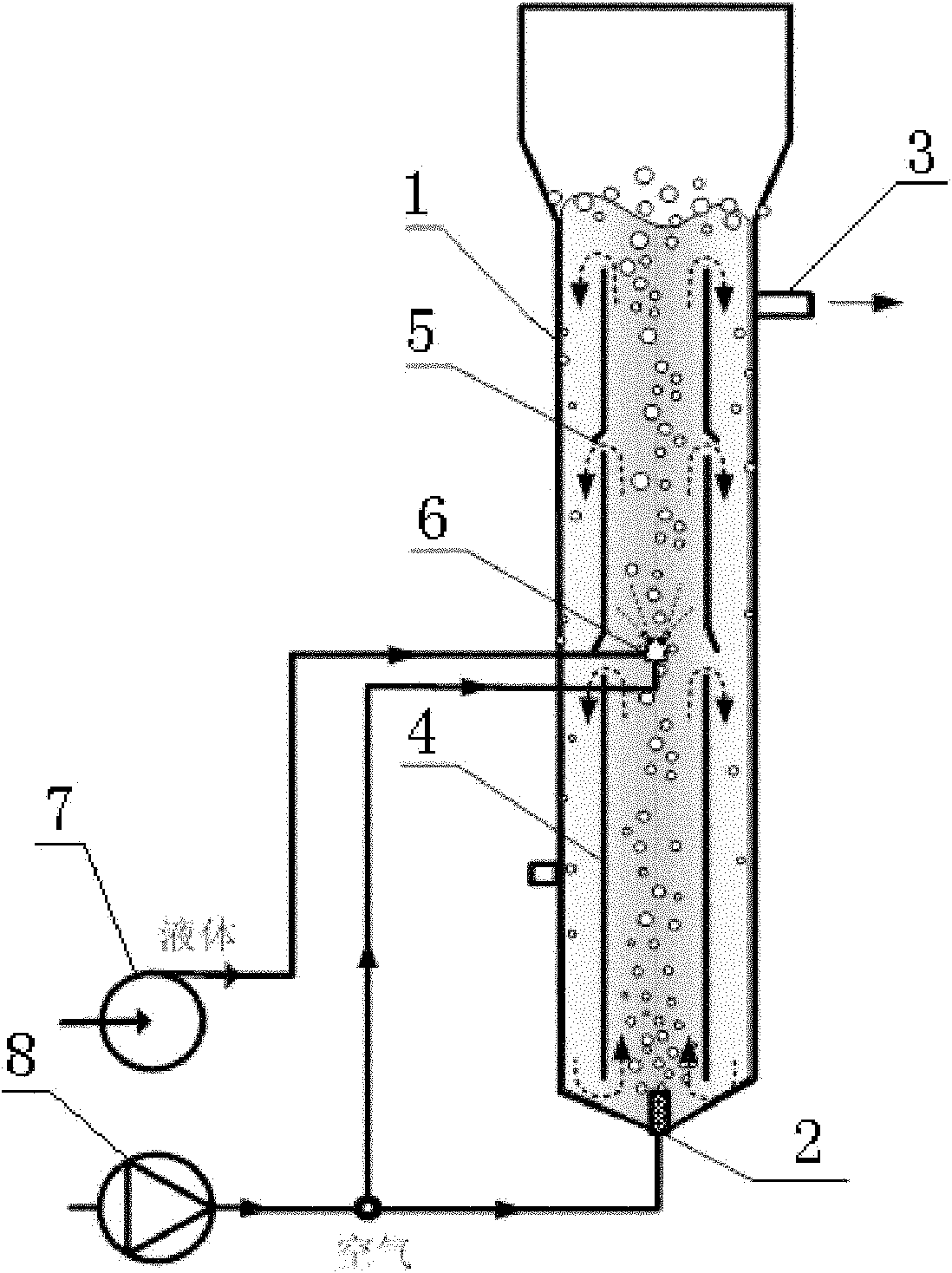

Airlift-jet multi-stage loop reactor

A loop reactor and jet technology, applied in the field of reactors, can solve the problems of high energy consumption and unsatisfactory gas-liquid distribution, and achieve the effects of low energy consumption, good mass transfer effect, and uniform gas-liquid distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

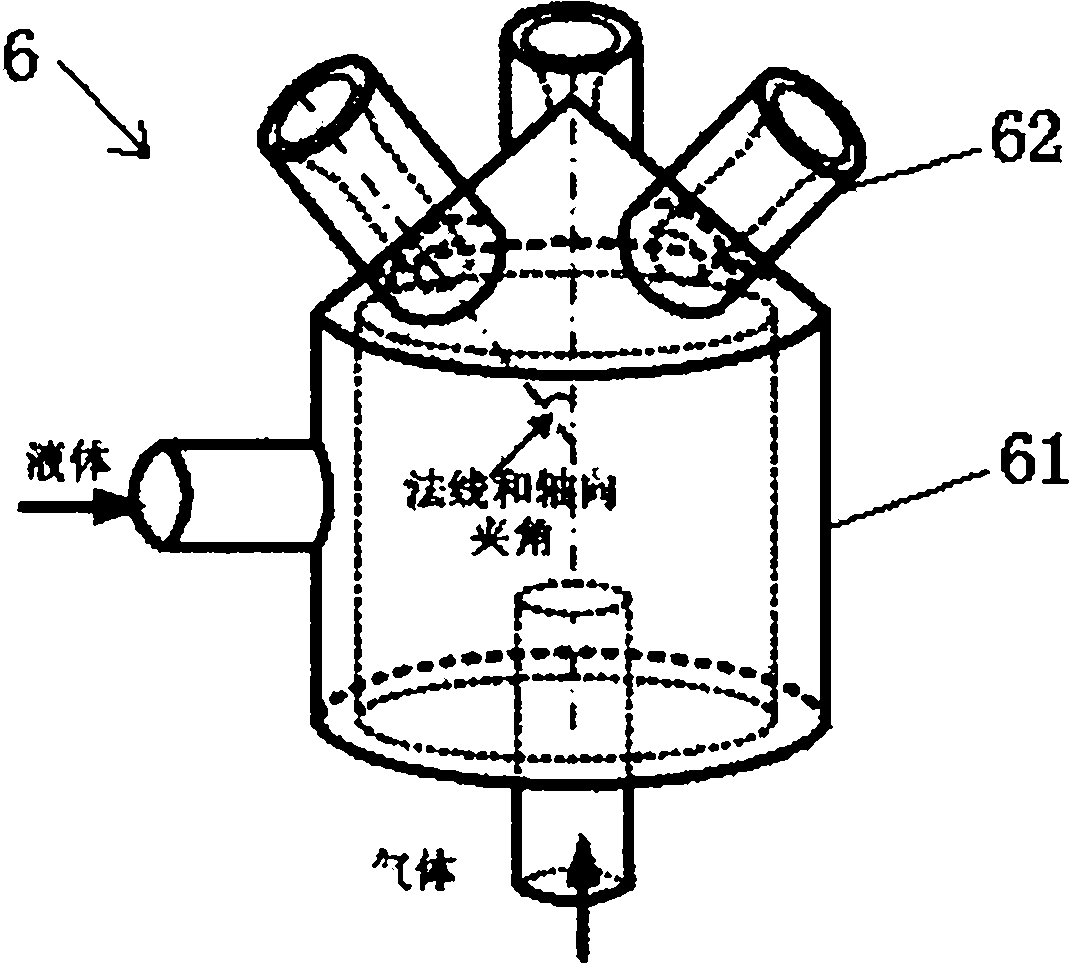

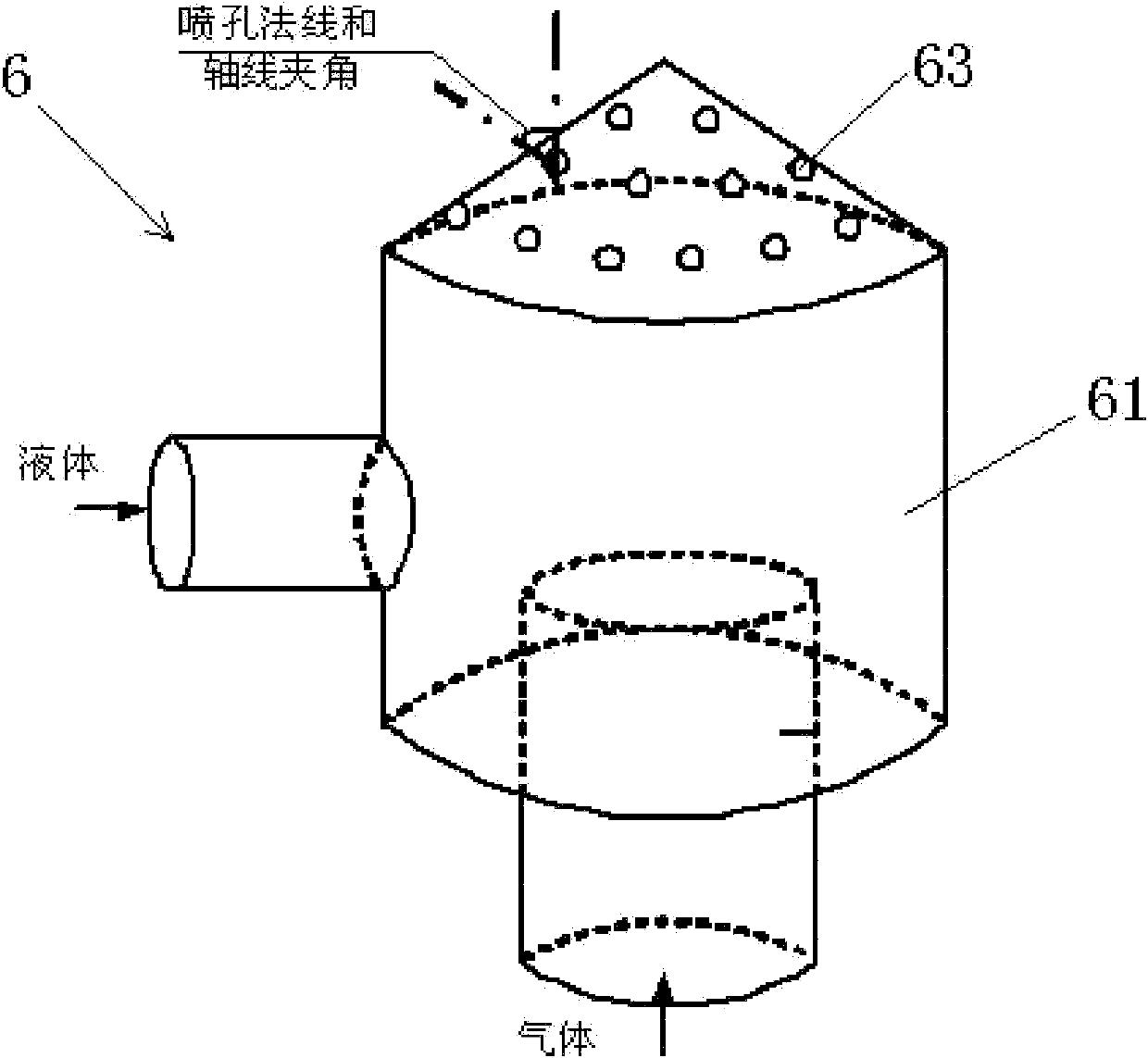

[0029] Embodiment 1: This embodiment is the hydrodynamic conditions in a 180L airlift-jet multi-stage loop reactor. The tower body 1 has a height of 3000mm and a diameter of 280mm. The diameter of the guide tube 4 is 213mm, and there are 3 sections in total, with a total height of 2130mm. The heights of each section of the guide tube 4 from bottom to top are 900mm, 400mm and 750mm in turn, and the gap between the adjacent sections of the guide tube 4 is 40mm . The distance between the lower edge of the guide tube 4 and the bottom of the tower body 1 is 100mm. The jet distributor 6 adopts such as figure 2 The shown form is installed in the first gap (H=940mm) at the lowermost end, and is composed of three nozzles with a diameter of 5mm, and the initial shot direction of the nozzles and the axis angle of the tower body 1 are 45 °. The total air flow injected into the tower body 1 is 100L / min (working condition, the same below), wherein, the air flow of the tower bottom gas d...

Embodiment 2

[0030] Embodiment 2: This embodiment is the influence of jet gas volume and liquid volume on jet effect. The settings and specifications of the tower body 1 and the guide tube 4 are the same as those in Example 1, and the experimental system is water-air. The total amount of gas injected into the tower body 1 is 100min / L (operating conditions, the same below), the liquid volume (L) is 24L / min, and the gas volume (V G1 ) and the gas volume injected by the jet distributor 6 (V G2 ) ratio V G1 :V G2 , and the ratio of jet liquid to gas volume L:V G2 At different times, the measured apparent circulation liquid velocity and volumetric gas holdup are shown in Table 1. In the control group, except that there was no jet flow, other conditions were the same, and the measurement results were as follows: Image 6 shown. Visible V G1 :V G2 In the range of 1:1~3:1, L:V G2 In the range of 1:3 to 1:1, the circulating liquid velocity and the volumetric gas holdup are increased to var...

Embodiment 3

[0033] Embodiment 3: This embodiment is the influence of the position of the jet and the angle of the first shot on the effect of the jet. The settings and specifications of the tower body 1 and the guide tube 4 are the same as those in Example 1, and the experimental system is water-air. Introduce the jet flow in the first gap (the plane where the nozzle is located from the lower edge of the draft tube height H=940mm) and the second gap (H=1380mm) from bottom to top of the draft tube 4 respectively. The total amount of gas injected into the tower body 1 is 100min / L (operating conditions, the same below), wherein the ventilation rate of the gas distributor 2 at the bottom of the tower is 60L / min, the ventilation rate of the jet distributor 6 is 40L / min, and the liquid The volume is 24L / min. The control group was under the same conditions except for no jet flow. The measurement results are shown in Table 2. It can be seen that the height of the jet flow position is within the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com